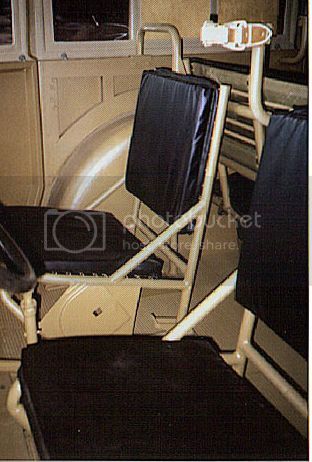

Not to detract from the wheel project that I am working on, but I realized that I really didn't have good shots of the gun itself...

So...

That is all... gotta go... for now...

)

)

Wich resin do you use to cast?

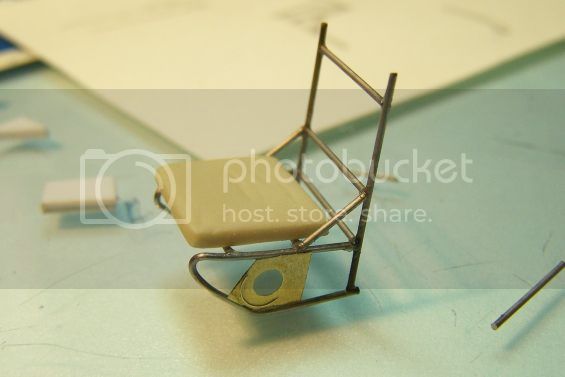

That resin set really leaves a lot up to the building.

Incredible work Jonathan! What have you used for the form? (rifle holders)

Phil.

Good progress. I have worked with several pe sets and found the only problem is stretching plastic rod to fit hinges. The devil is in the details. Your work has inspired me. I am planning on adding a 2.5cm flak to Tamiya's old sdkfz 251/1. This kit lacks a lot of interior detail, so I will button up the top and have the gun slightly inset.

|