I 3D Printed some Tanks!!!

Al Qahirah, Egypt / لعربية

Joined: October 06, 2013

KitMaker: 244 posts

Armorama: 180 posts

Posted: Saturday, September 27, 2014 - 10:39 PM UTC

I'd rather regret doing some things in my life than to regret having done nothing with my life...

Al Qahirah, Egypt / لعربية

Joined: October 06, 2013

KitMaker: 244 posts

Armorama: 180 posts

Posted: Saturday, September 27, 2014 - 10:47 PM UTC

The home 3D printing technology is still in its early stages, the finishes achieved with these printers are not a match for the finish and details level of ready kits.

But I believe as technology develops the 3D printer will become an essential tool for every scale modeler.

Imagine going on Tamiya or Verlinden websites and buying 3D designs of figures and vehicles and printing them instantly without waiting for shipping. Imagine being able to adjust the scale, the posture of your figures or adding upgrades and parts to tanks or making bases and sceneries according to your imagination. Putting it all together and printing it.

But would modernizing our hobby to that extent spoil the fun of making it? What do you think??

I'd rather regret doing some things in my life than to regret having done nothing with my life...

Al Qahirah, Egypt / لعربية

Joined: October 06, 2013

KitMaker: 244 posts

Armorama: 180 posts

Posted: Saturday, September 27, 2014 - 10:50 PM UTC

Another example of a figure bust that I recently printed:

Still raw, haven't been primed or painted!

I'd rather regret doing some things in my life than to regret having done nothing with my life...

Al Qahirah, Egypt / لعربية

Joined: July 23, 2004

KitMaker: 6,856 posts

Armorama: 6,363 posts

Posted: Saturday, September 27, 2014 - 10:58 PM UTC

That's pretty interesting stuff... how much did that printer set you back.. and how about the material you use for the printing?

Hisham

Vermont, United States

Joined: July 21, 2002

KitMaker: 3,569 posts

Armorama: 2,070 posts

Posted: Sunday, September 28, 2014 - 01:59 AM UTC

Hello,

Your 3D printed tanks look like great fun, and like scratchbuilding, a big part of the enjoyment of any project has to be in the figuring out the best way to accomplish something.

Thanks for the link to thingiverse.com

I'm just dipping my toes into the waters of 3D printing with a course for teachers using printers in the classroom. I am starting to look around for other online resources/communities.

It will be interesting to enter a new area of interest at the ground floor and not be one of the 'crusty old know it all guys'.

A little newb is good for the soul.

Do you visit other communities? I have a decent computer background, but not a drafting/machining/imaging skillset, yet.

Any suggestions where to start dipping my toes into these new waters?

Mike

If you can keep your head when all about you are losing theirs,

perhaps you've misunderstood the situation.

Al Qahirah, Egypt / لعربية

Joined: October 06, 2013

KitMaker: 244 posts

Armorama: 180 posts

Posted: Sunday, September 28, 2014 - 02:13 AM UTC

Thanks Hisham

I bought mine refurbished for 399 USD, a brand new one would start at about 699 USD

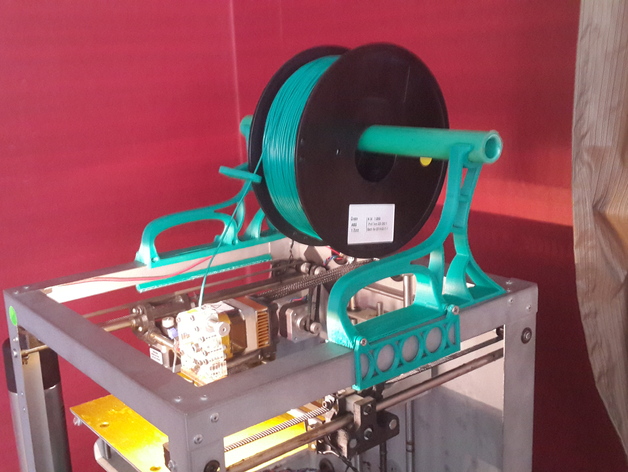

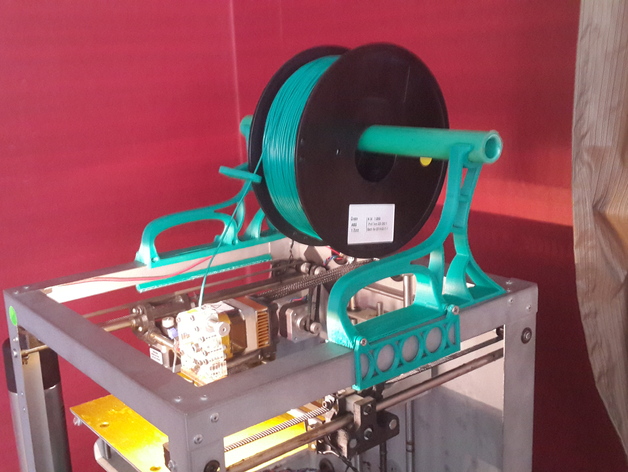

The Material used is ABS plastic, its sold in the form of a plastic wire (filament) that you feed into the printer and then it melts and comes out of the nozzle. Its quite a strong material.and the cost of the material is almost nothing, you can buy one kilo of abs filament for 20 USD and one kilo can last you for many many prints.

Here is how it looks:

I'd rather regret doing some things in my life than to regret having done nothing with my life...

Al Qahirah, Egypt / لعربية

Joined: October 06, 2013

KitMaker: 244 posts

Armorama: 180 posts

Posted: Sunday, September 28, 2014 - 02:20 AM UTC

Hi Mike,

You are right, 3D printing requires a lot of setup skill.

You can acquire such skill but looking into the forums on the 3D printer brand you are looking to buy, there are also some brands that provide very easy to use manuals and have also very good support and documentation and videos to get you started.

Other than that all you need is creation and imagination and off you go for a lot of fun. Its soooo interesting watching the 3d printer in action as things start to come to life from the design to real life material item that you can touch.

On thingiverse you will find millions of designs for so many creative ideas that you can print and use, what's even more mind blowing is that you can actually print some parts to upgrade your printer so in a sense your printer is building and improving itself.

Then if you really want to get into this stuff you could take a 3D design course then you would be able to create your own designs and print them.

i think there should be a website for 3D designs dedicated to scale modelers that they can download and print.

I have found a lot of diorama printable components on thingiverse but a dedicated website would be great.

I'd rather regret doing some things in my life than to regret having done nothing with my life...

Vermont, United States

Joined: July 21, 2002

KitMaker: 3,569 posts

Armorama: 2,070 posts

Posted: Thursday, October 16, 2014 - 11:35 AM UTC

So I ( all right, my school district ) am the proud owner of a Da Vinci 1.0 printer and the course has started.

Eventually we will be designing some 3d objects in Blender and in Tinkercad, but for now Thingiverse has Vallejo bottle racks, brush rests, glue bottle supports and about 6 million other things.

Above are my printed (not designed, but printed) Vallejo 3x2 paint holders. With this printer at 'fast' setting it still takes 1.5hrs to print this. The 5x5 will take 5 hrs..

They have very good strength both top, side and torque. Only drawback so far is that the paint numbers are obscured, but I can figure a work-around.

Resolution is nothing near what I would want for model parts, but for the sheer cool factor, it cant be beat!

Mike

If you can keep your head when all about you are losing theirs,

perhaps you've misunderstood the situation.

New York, United States

Joined: May 27, 2013

KitMaker: 2,210 posts

Armorama: 1,712 posts

Posted: Thursday, October 16, 2014 - 01:13 PM UTC

I like this... If I could I'd buy some of these kits (just cause

)

But those bottle holders I'd definitely want to get.

I do some 3D design work. Message me for more info on what I'm doing or have done. Inquire about a product catalog.

Vermont, United States

Joined: July 21, 2002

KitMaker: 3,569 posts

Armorama: 2,070 posts

Posted: Thursday, October 16, 2014 - 01:40 PM UTC

Even better, with some calipers and a little math, I can enlarge the rack for Ammo/Mig or the tiny tippy Akan bottles, reduce the height for the smaller Tamiya bottles or pretty much anything I want...

Also in thingiverse are several laser cutter plans for Tamiya bottles or Vallejo bottles to do larger numbers of bottles at once.

now to find someone with a laser cutter...

Mike

If you can keep your head when all about you are losing theirs,

perhaps you've misunderstood the situation.

New York, United States

Joined: May 27, 2013

KitMaker: 2,210 posts

Armorama: 1,712 posts

Posted: Thursday, October 16, 2014 - 02:29 PM UTC

Yep. Actually... I've been thinking about picking up some masonite to cover my desk that I recently cleaned off and am now using as my new model desk (from the living room coffee table, to the living room floor, to my bedroom floor, to my bedroom desk... I'm moving up in life!). So I might pick up some thing plywood and cut some holes, cut some slots, use some glue and I might make my own paint holder.

I do some 3D design work. Message me for more info on what I'm doing or have done. Inquire about a product catalog.

JPTRR

Managing Editor

Managing Editor

#051

Tennessee, United States

Joined: December 21, 2002

KitMaker: 7,772 posts

Armorama: 2,447 posts

Posted: Thursday, October 16, 2014 - 03:04 PM UTC

Hussein,

Amazing! The bust, especially.

If they demand your loyalty, give them integrity; if they demand integrity, give them your loyalty.--Col John Boyd, USAF

“Any plan where you lose your hat is a bad plan.”

ColinEdm

Associate Editor

Associate EditorAlberta, Canada

Joined: October 15, 2013

KitMaker: 1,355 posts

Armorama: 1,229 posts

Posted: Thursday, October 16, 2014 - 04:35 PM UTC

The voices are back.....excellent....

Ontario, Canada

Joined: November 03, 2012

KitMaker: 2,275 posts

Armorama: 2,233 posts

Posted: Thursday, October 16, 2014 - 05:38 PM UTC

#037

California, United States

Joined: December 19, 2004

KitMaker: 2,870 posts

Armorama: 1,458 posts

Posted: Friday, October 17, 2014 - 02:30 AM UTC

Like the bust a lot. Pretty good detail all around. I've been watching this tech evolve for a while now and it all boils down to detail replication and production speed. So far, the detail capability for 1/35 or 1/32 figures is not there yet. Basic furniture and other every day items like drums, barrels, crates, etc. are OK. Lack of production speeds limits the tech to making mold masters or custom one-offs or pairs. Detail improvement will probably be achieved first and then speeds will follow.

"It's not where you start.It's where you finish"-Model On!!!!

"I just drank what?"-Socrates

If the enemy is in range, so are you.......

'Impossible' means you haven't thought of the solution yet........

Texas, United States

Joined: June 12, 2007

KitMaker: 1,866 posts

Armorama: 1,696 posts

Posted: Friday, October 17, 2014 - 03:39 AM UTC

Anybody remember the first TI calculators? And then how fast they got tiny and cheap?

Hold on to your hats, it's coming.

Vermont, United States

Joined: July 21, 2002

KitMaker: 3,569 posts

Armorama: 2,070 posts

Posted: Sunday, November 23, 2014 - 07:21 PM UTC

So, my 'project' for this 3D printing class.

PST's 1/772 T55 plus my legs and chassis. Legs articulate at the 'hip' and there are other bits as shins and feet, but I like this look. I will probably add feet to these legs.

Mike

If you can keep your head when all about you are losing theirs,

perhaps you've misunderstood the situation.

Quebec, Canada

Joined: January 01, 2004

KitMaker: 7,600 posts

Armorama: 6,110 posts

Posted: Sunday, November 23, 2014 - 08:02 PM UTC

Isn't the printing medium expensive? In the case of inkjet printers, the printers are now relatively cheap - constant ink refills not so much.

North Carolina, United States

Joined: June 06, 2006

KitMaker: 4,691 posts

Armorama: 3,509 posts

Posted: Sunday, November 23, 2014 - 08:15 PM UTC

Well the figure looks real good.the tanks look...well...as my wife would say,cute.they almost look edible.Like you said,the technology for home use is still young

Bayern, Germany

Joined: October 22, 2013

KitMaker: 380 posts

Armorama: 376 posts

Posted: Sunday, November 23, 2014 - 08:41 PM UTC

Iterresting seeing someone really using a 3D-printer for real modelling purposes.

I´ve had the chance to work with the Ultimaker2 (fantasic printrer, but a bit too expensive for my home use) on some rapid prototyping stuff.

As you´re printing ABS you could try "vapor softening" to improve your print results. By "bathing" your prints in Acetone vapors you can get rid of the print lines and achive a glossy and absolutely even finish. Might work better on the bust than on tanks with sharp edges. There are enough tutorial out there to get you started.

Impossible only means that you haven't found the solution yet.

Vermont, United States

Joined: July 21, 2002

KitMaker: 3,569 posts

Armorama: 2,070 posts

Posted: Sunday, November 23, 2014 - 10:55 PM UTC

Quoted Text

Well the figure looks real good.the tanks look...well...as my wife would say,cute.they almost look edible.Like you said,the technology for home use is still young

Actually the ABS plastic is pretty affordable, this printer uses a proprietary pre-loaded cartridge with a chip to tell the printer it is out, but there is a workaround for that.

Spools of ABS are less than the cost of a kit $25-30 depending, per kilo.

If you can keep your head when all about you are losing theirs,

perhaps you've misunderstood the situation.

Bayern, Germany

Joined: October 22, 2013

KitMaker: 380 posts

Armorama: 376 posts

Posted: Sunday, November 23, 2014 - 11:09 PM UTC

@Mike: Almost forgt about it. If you´re searching for a really good troubleshooting/ print improving guide take a look at this:

http://support.3dverkstan.se/article/23-a-visual-ultimaker-troubleshooting-guideAlthough it´s written for the Ultimakers, you can adapt it for other printers aswell. Simply compare your print with the pictures, find out whats "wrong" and try to adapt it to your printer. In the case of your paint rack (judgeing that by the look of your top surface) it might be that your printbed is calibrated slightly too low (but just a "µ", as we say here), or your printer suffers from "underextrusion".

3D-Printing is a bit of a trial and error game, it took me about two weeks to get it the printer to optimal results. Have fun trying.

Impossible only means that you haven't found the solution yet.

United States

Joined: June 02, 2013

KitMaker: 202 posts

Armorama: 199 posts

Posted: Monday, November 24, 2014 - 01:45 AM UTC

I have a Printrbot myself. Never managed to make anything tank related with it though. Mainly prototyping work. Never made anything as good as that bust either.

It's up for grabs though, if anyone wants to get into the hobby for cheap (relatively speaking).

Al Qahirah, Egypt / لعربية

Joined: October 06, 2013

KitMaker: 244 posts

Armorama: 180 posts

Posted: Monday, November 24, 2014 - 02:20 AM UTC

There should be a 3d printing repository of designs for scale modelers...there is a bunch of useful things we could print on 3D printers such as diorama accessories (drums, concrete blocks...etc) there could be also some interesting busts.

Its true that all my trial to print large scale tanks were not successful and the finish quality not comparable to ready kits

I'd rather regret doing some things in my life than to regret having done nothing with my life...