I was cleaning up my harddrive and found some pictures of my 'sound-reducing-air-compressor-box project'.

Although it's not a recent project I'm still very happy with this box and I though it might inspire some people here to make their own.

It reduces the noise to about 40-50%, a big improvement in my opinion.

So here's an overview of the project:

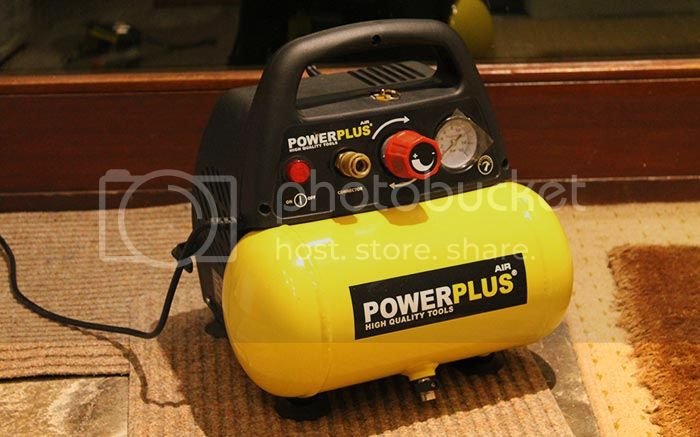

This is my compressor, it's a small oil-free 'PowerPlus' (Same as 'Stanley DN200/8/6') with a 6 liter tank (96 db).

Despite the noise, I am very satisfied with this machine, the output pressure is adjustable and it is pretty compact.

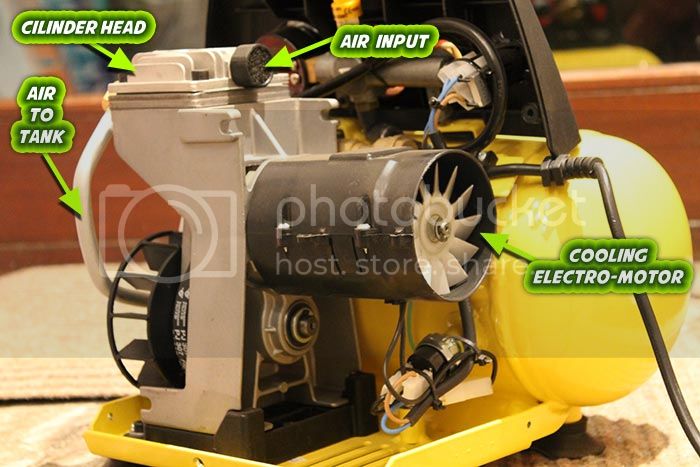

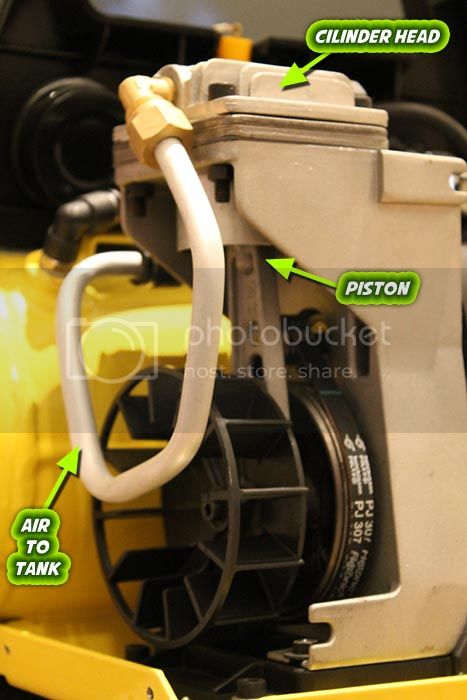

First I screwed it apart to see how everything works and which parts makes noise ...

(I showed the basic parts in the picture)

I thought about how I would build it and also searched the web for ideas and techniques.

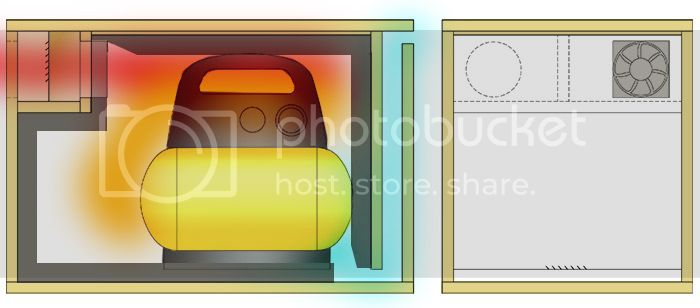

Eventually I drew the plan below, this seemed like a fairly compact solution.

(blue is fresh air, red is heated air to dissipate)

Then started sawing panels (18mm MDF) and gluing them together.

I also used wheels to make the box some more mobile, here I'm (pre)drilling the holes for the screws.

The wheels could produce some contact-noise, so when airbrushing the box is put on 4 foam tubes (cut from swimming pool toy).

After gluing I rounded the corners with a router.

First coat of white primer with a paint roller.

Painted and drying

There is a 90mm 12V pc-fan inside the box to remove the heat.

To minimize the contact-noise I made a small sound absorber from 2mm foamboard.

Cutting the hole:

Screwing the fan on the wood.

Other side

After that I glued the panel in place.

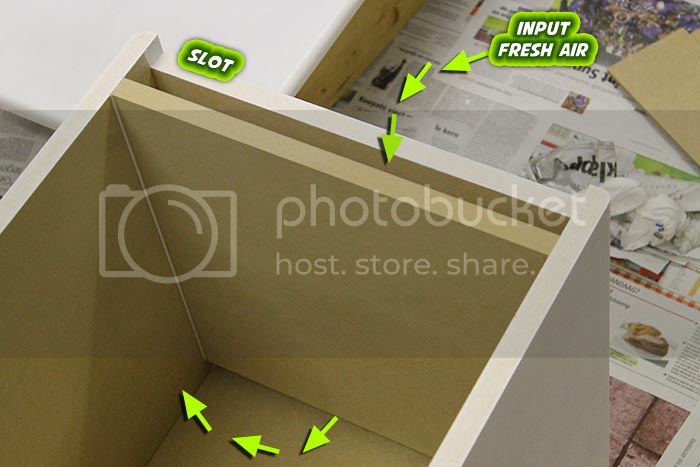

The 90mm fan has a good flow rate, so in order to prevent it sucking a vacuum in the box, there must be a fresh air inlet.

I had calculated the surface area of the fan-hole and then provided an air inlet a little larger.

Below you can see the air inlet, The fan sucks air through the slot in the box (the green arrows)

All panels are glued... (left heat-outlet, right fresh air inlet)

At the bottom of the lid I glued 6mm MDF to properly seal the lid.

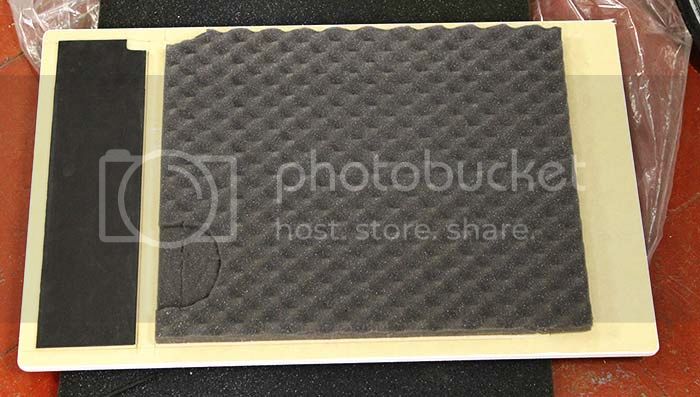

I putted black sound insulation on the inside, glued here and there with a hot glue pistol ...

All pieces first cut to size and then mounted ...

The 90mm fan is powered with a 12 volt adapter, the fan draws about 300mA according to the sticker.

Below I soldered the fan to the adapter ...

When everything was sound isolated, the compressor went into the box...

I put a socket in the box in which both the compressor and the 12V adapter are plugged in...

In the heat exhaust passage I glued two more cross pieces and I coated the wall with 2mm black foam board, this to avoid noise-rays bouncing as much as possible.

At the bottom of the lid I also glued sound-insulation...

I then did a sound test with the compressor on and the box closed, and the result was pretty good.

The remaining noise came from the air-inlet-slot because there was no filter and the sound-rays could just bounce between the walls of the slot.

For this I made a weird filter based on this link : http://www.artifacturestudios.com/archives/985/

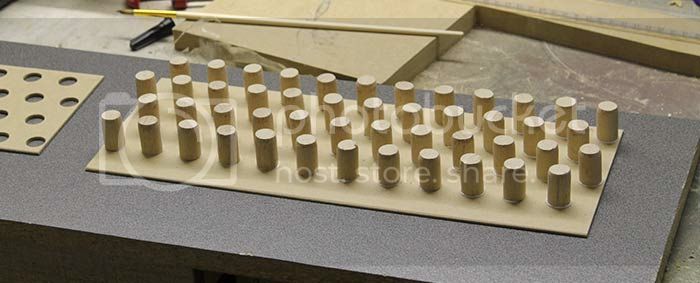

I drilled about 48 holes in each plate, and then sawed 48 dowels from a 15mm thick pole...

Then glued those dowels in the holes...

And the sound-filter was ready to install, the sound waves go through the dowels and get filtered at a certain frequency depending on the size and distance of the dowels.

The filter in place, between the walls of the air-inlet.

So this is the final box, air inlet

hot air outlet

So it reduces the sound quite well, The box is set-up under a desk, hovering on 4 pieces of foam tube.

The heat dissipation works very good, because it gets cooled constantly and only producing heat when it starts pumping.

hopefully this can inspire some of you who are about building their own compressor box, your neighbors will love it!

Thanks for reading and good-luck with your projects!

Kind regards,

Steven