A number of AM resin manufacturers make what they call burnt or damaged Sherman road wheels w/o rubber tyre. Here is a question:

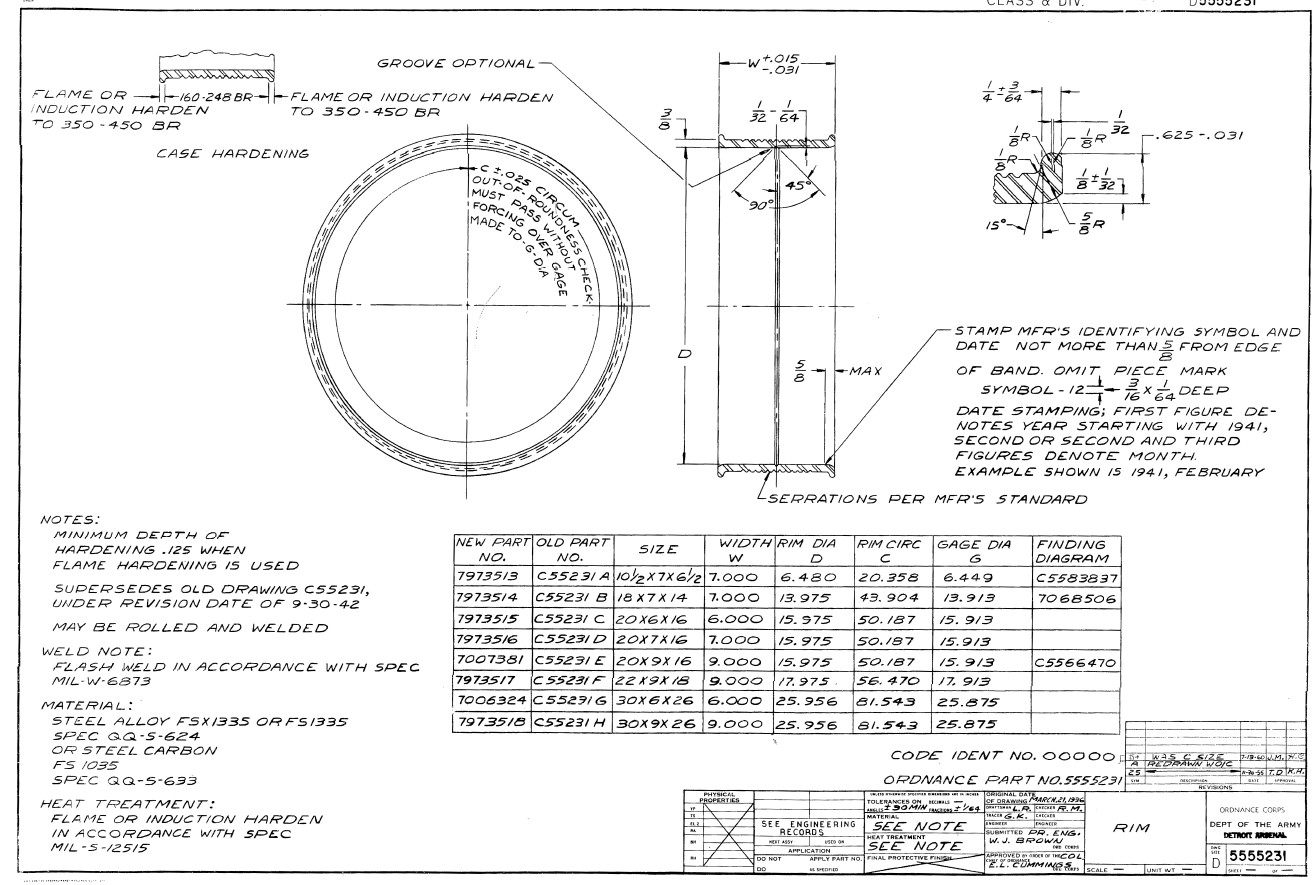

were those wheels really smooth or should they have some grooves for

better grip of the tyre like T-34 and the likes in German service (Pz.III/Pz.IV)? I can't find neither drawings nor decent resolution images of the thing.

Thanks in advane!