Thanks, Nick. It must have been raining when the photo of China Clipper was taken, based on all the mud. Makes me wonder how there is any soil left in France because you would think it was all carried away on tanks.

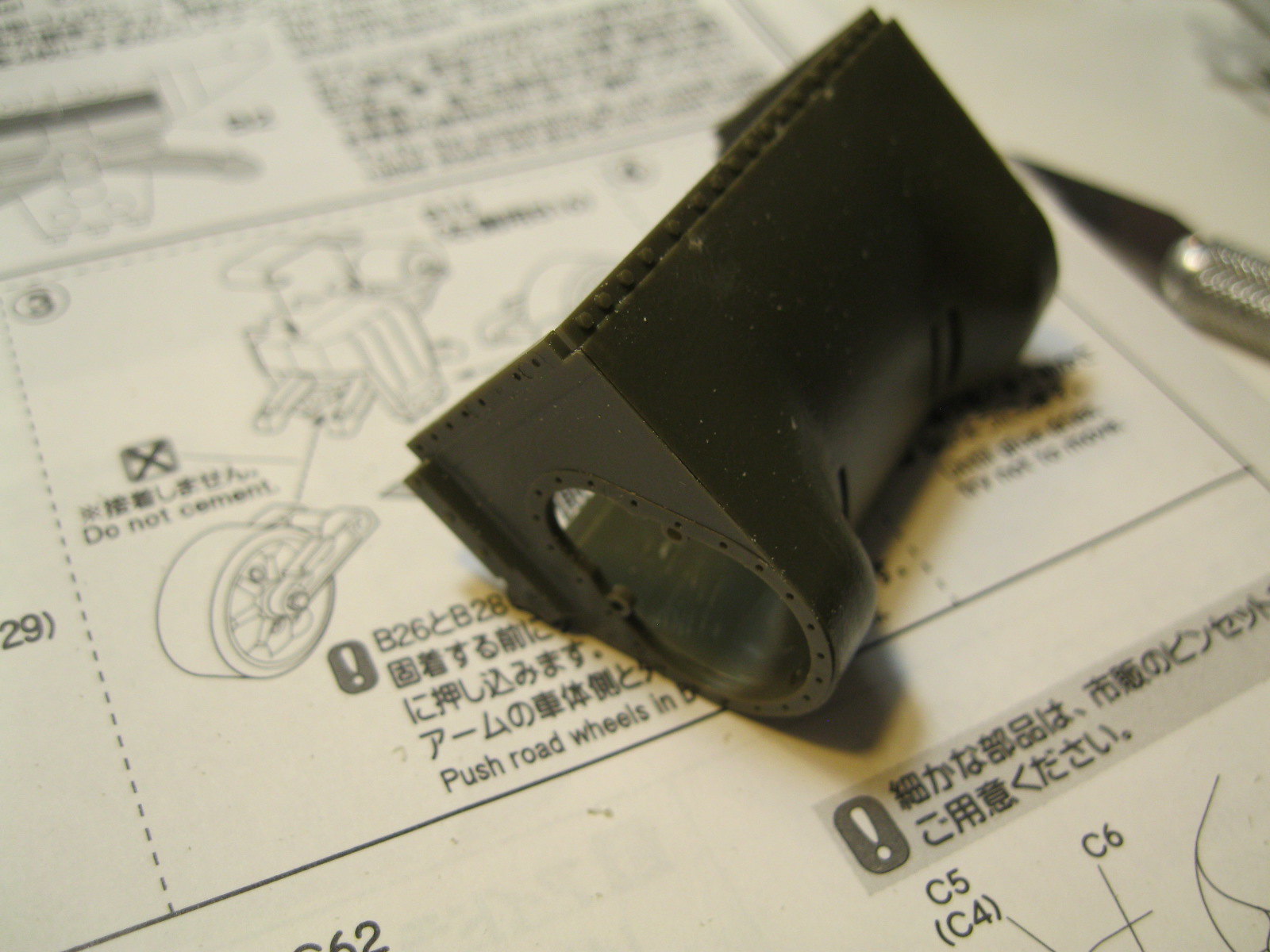

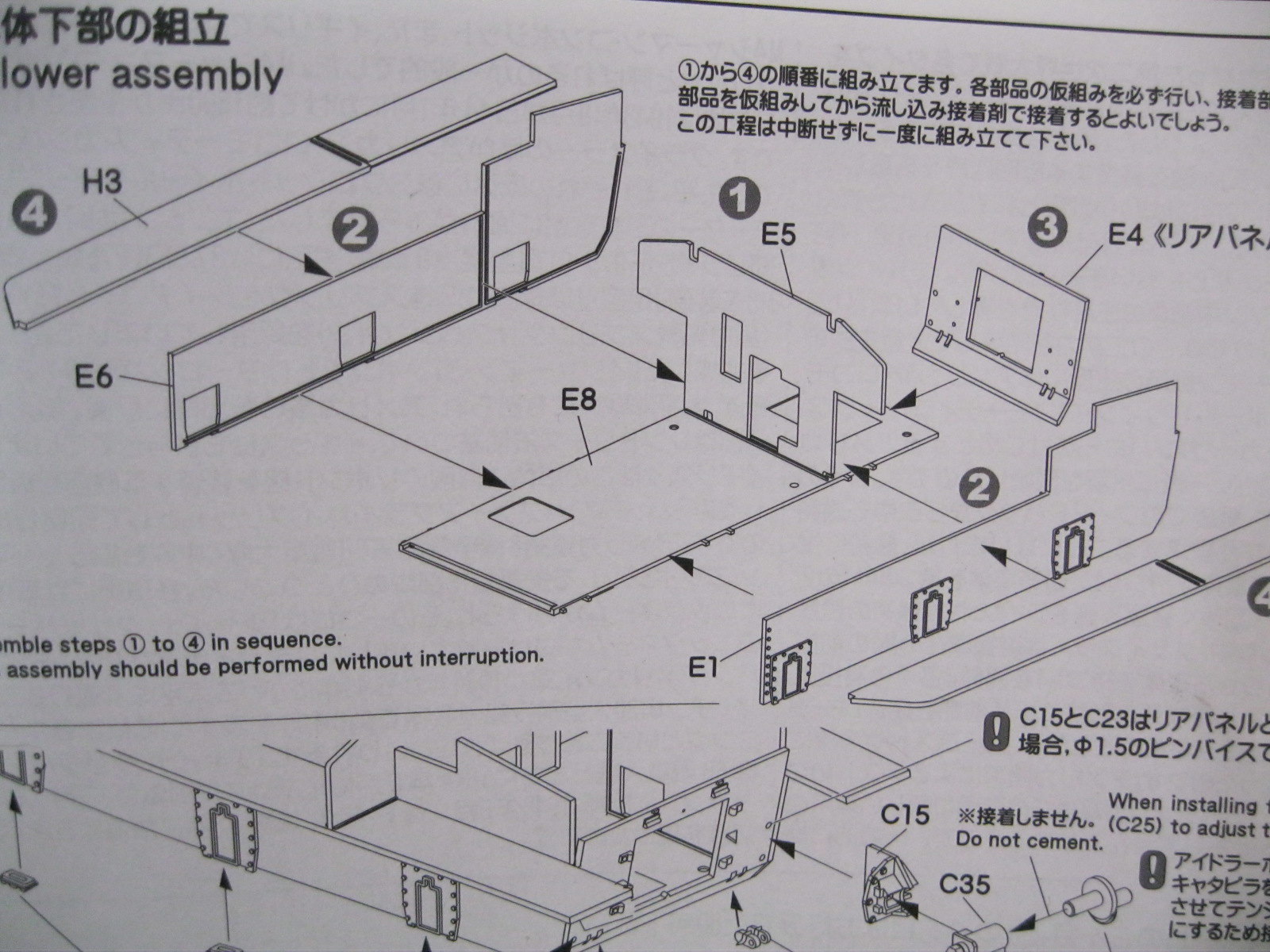

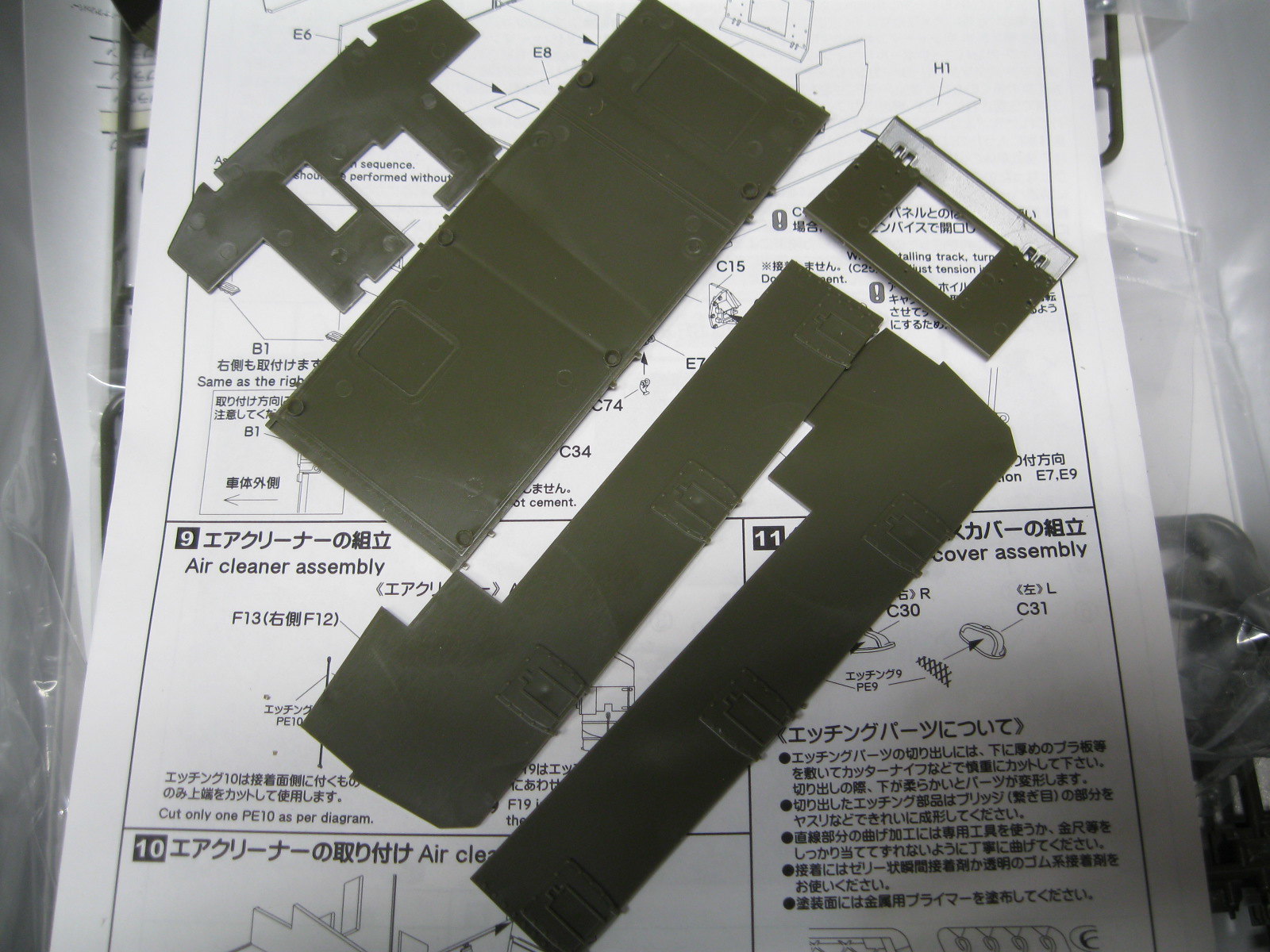

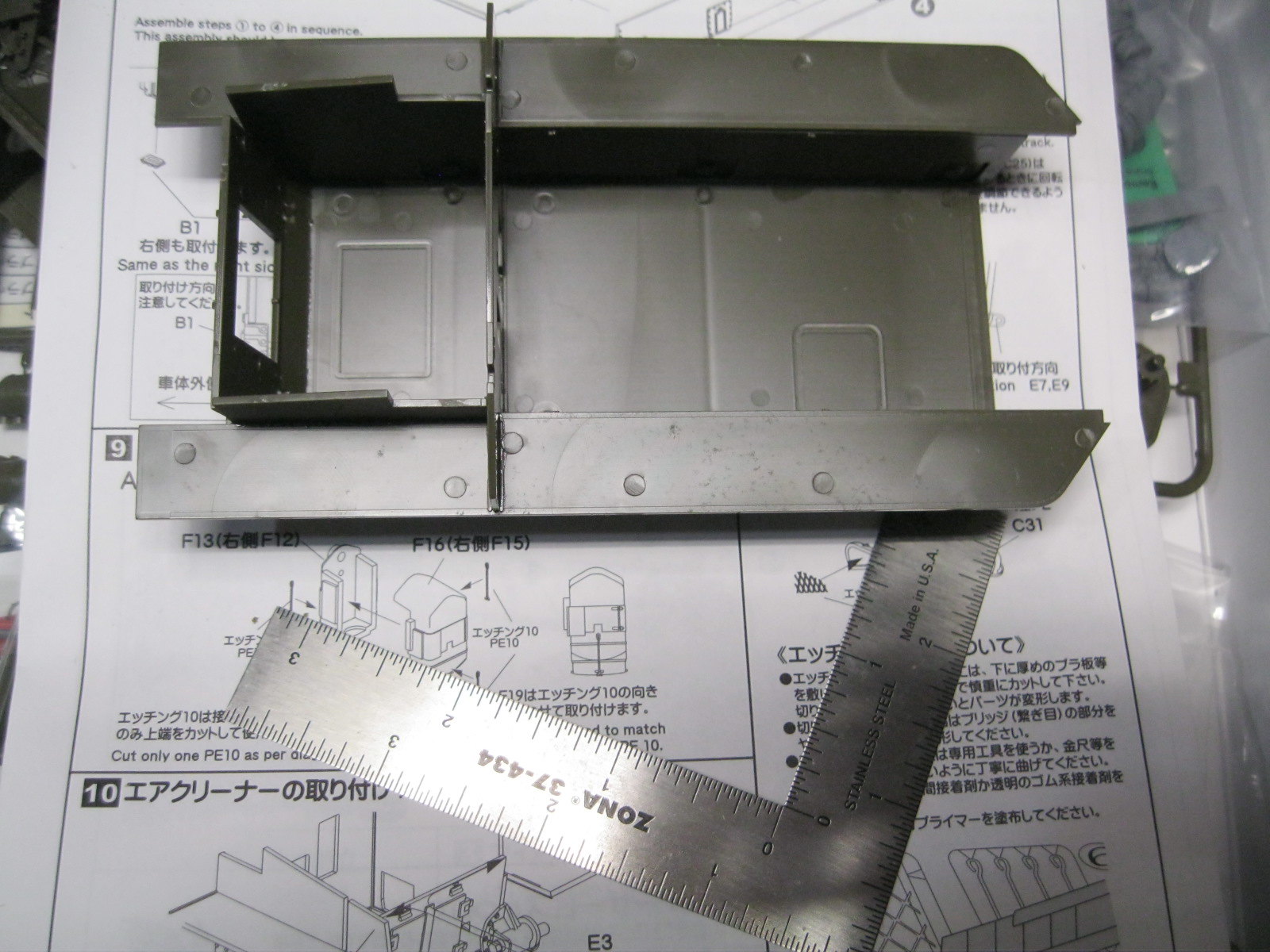

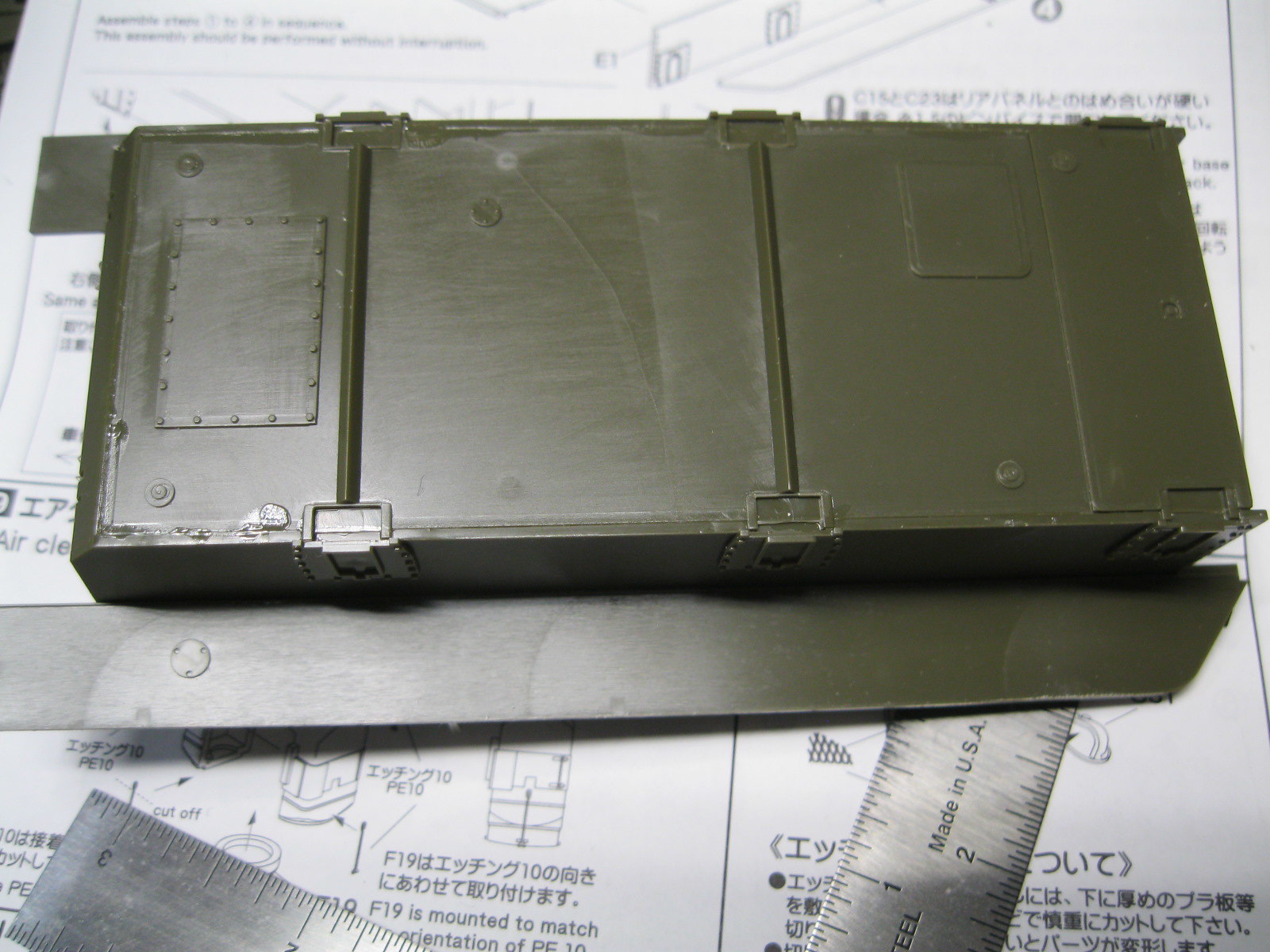

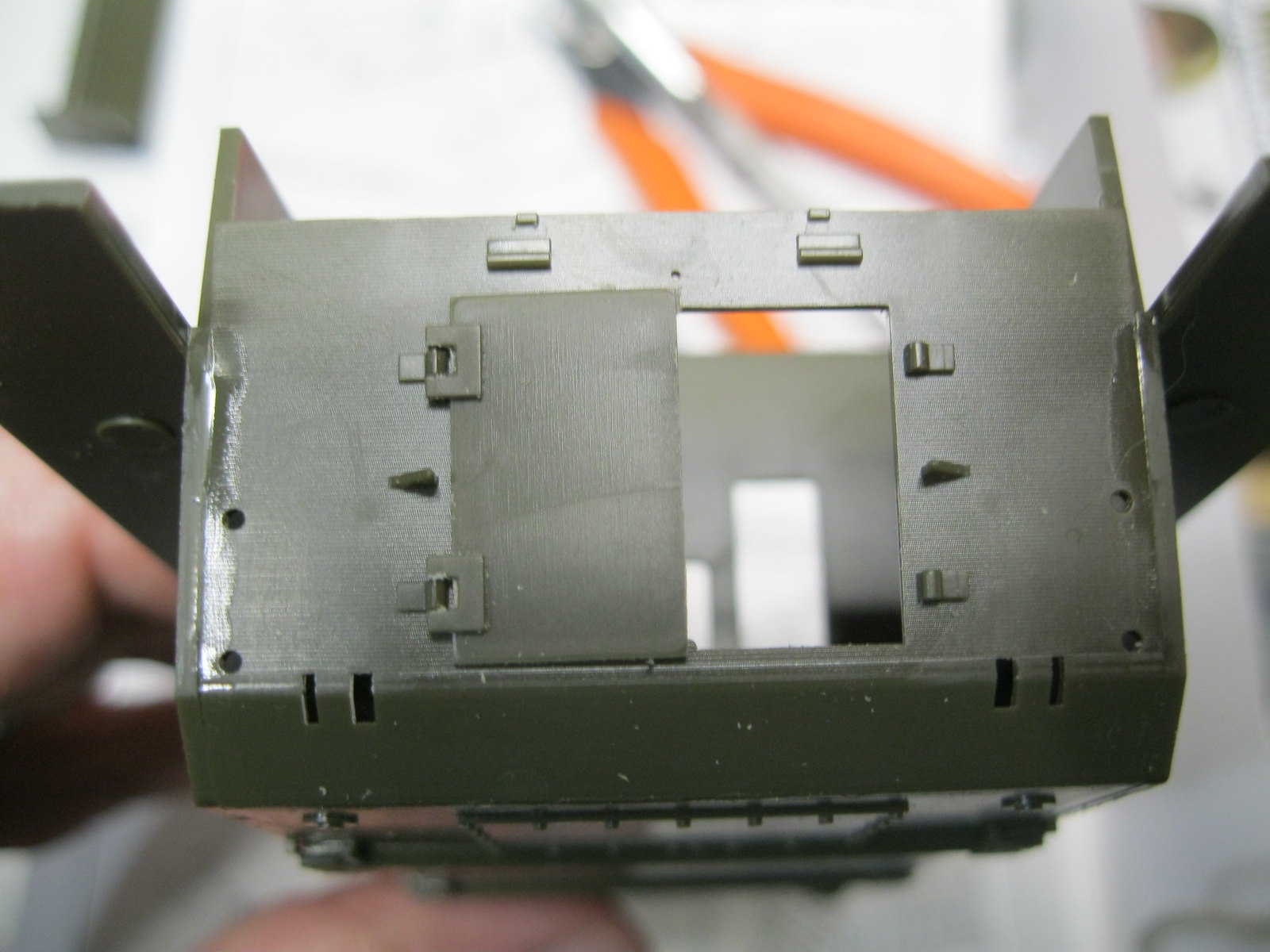

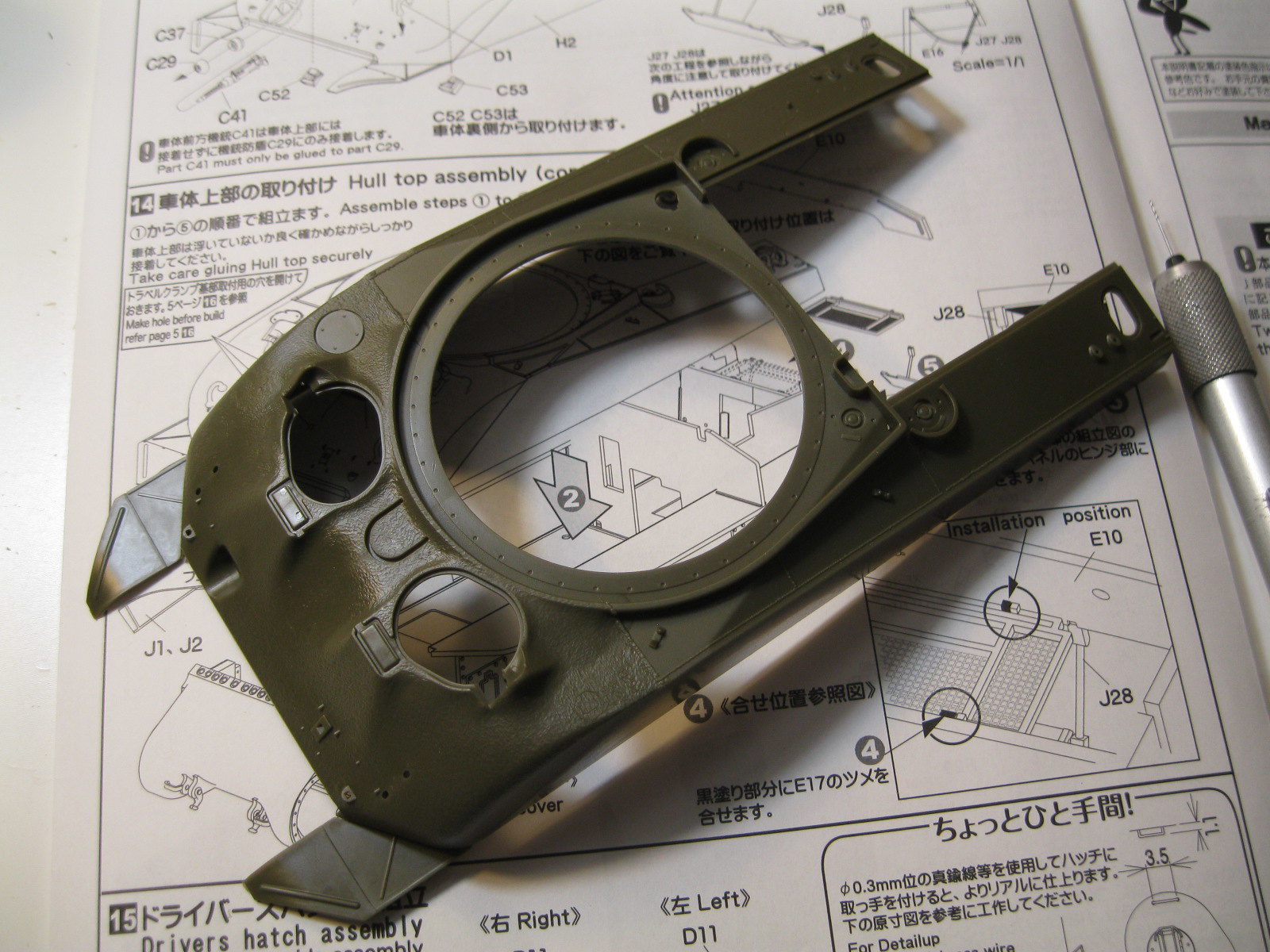

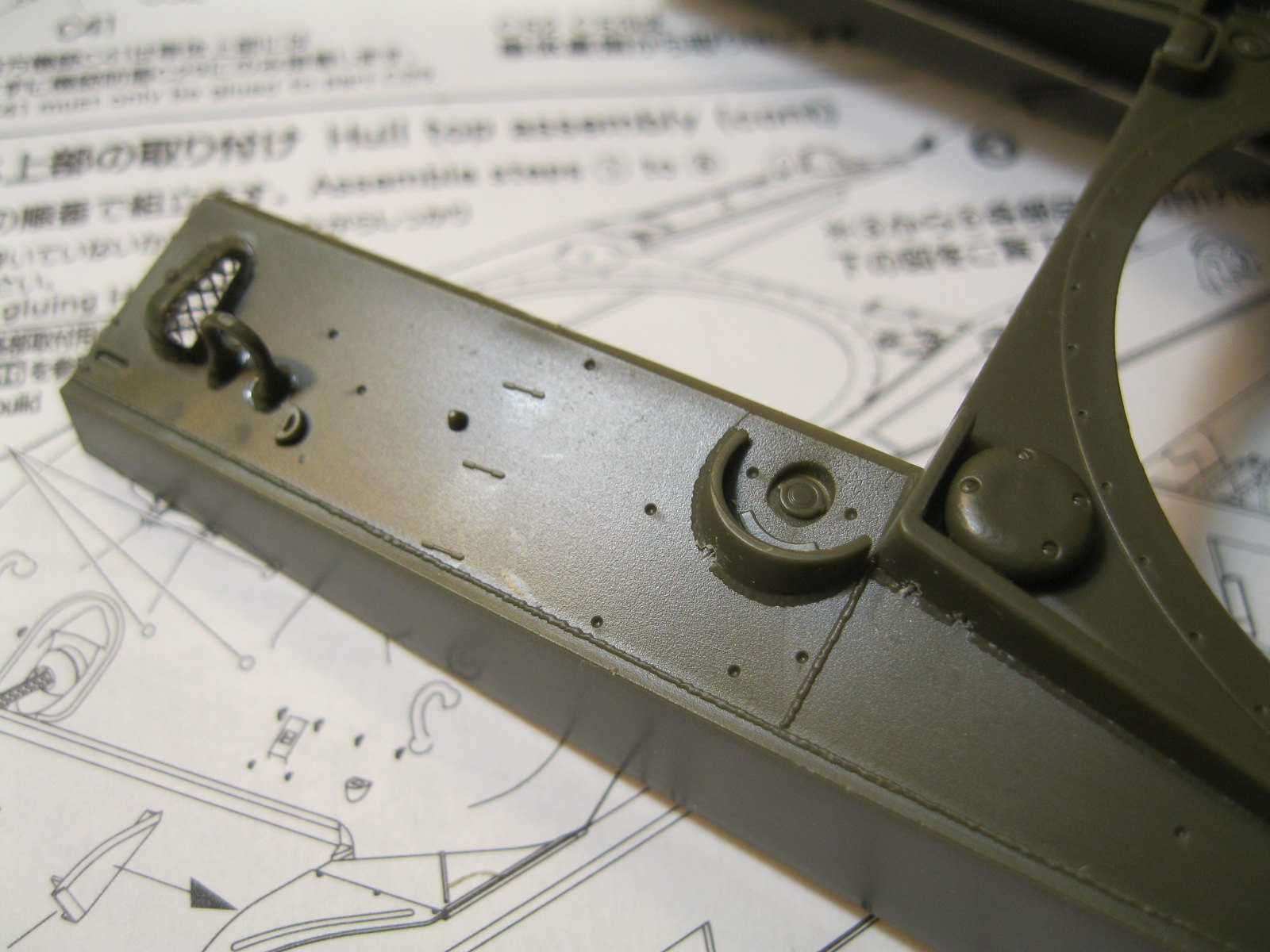

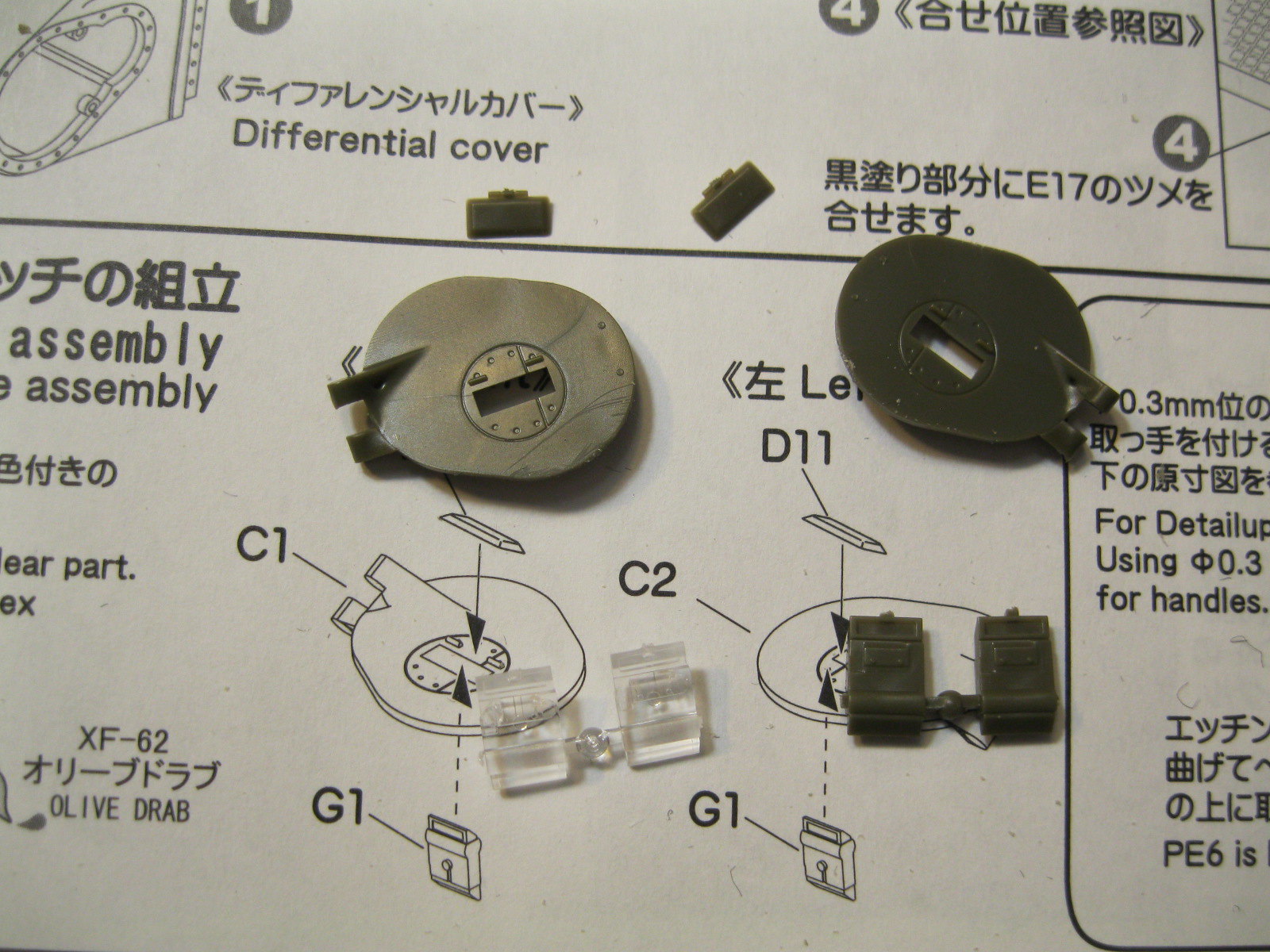

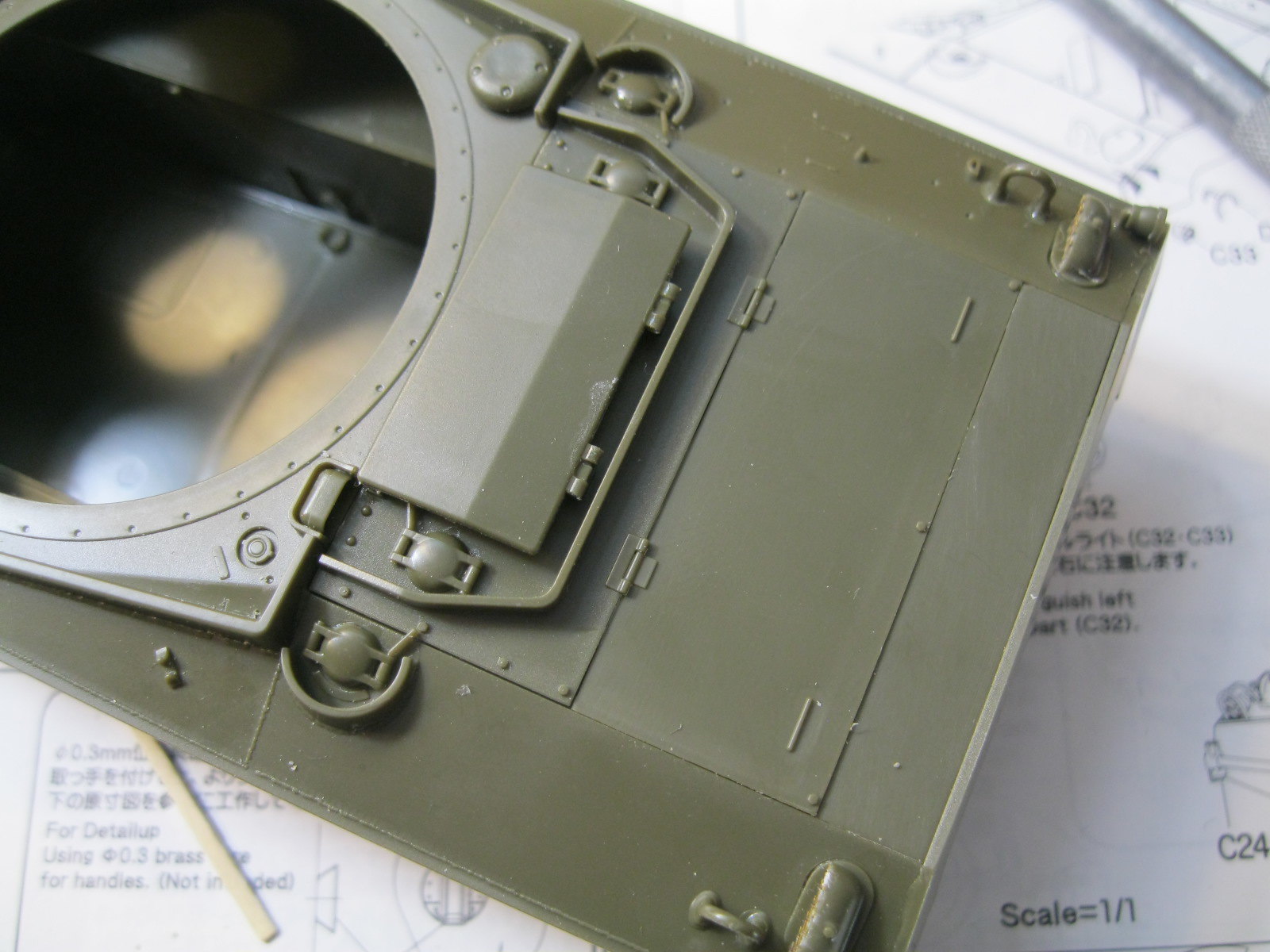

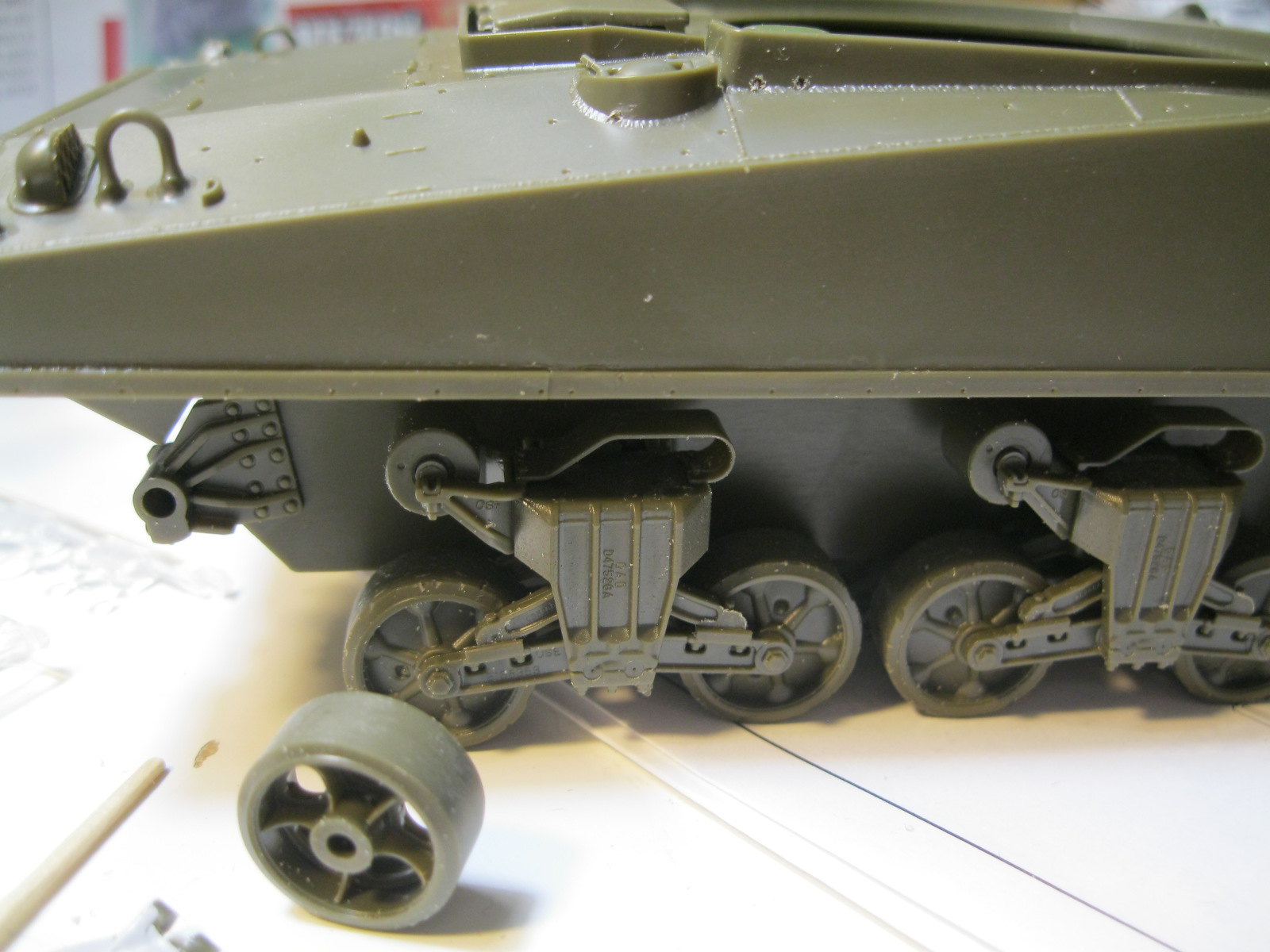

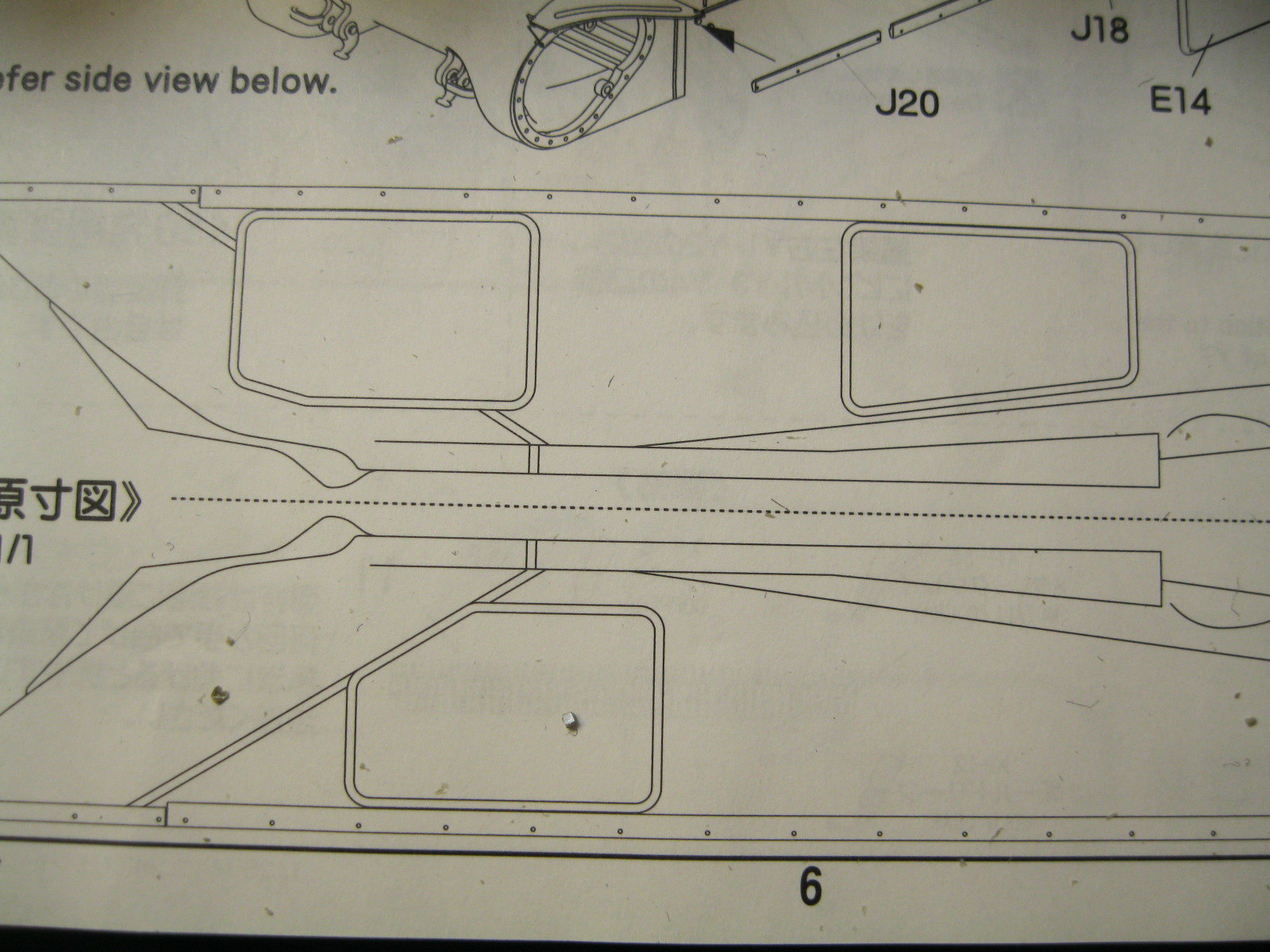

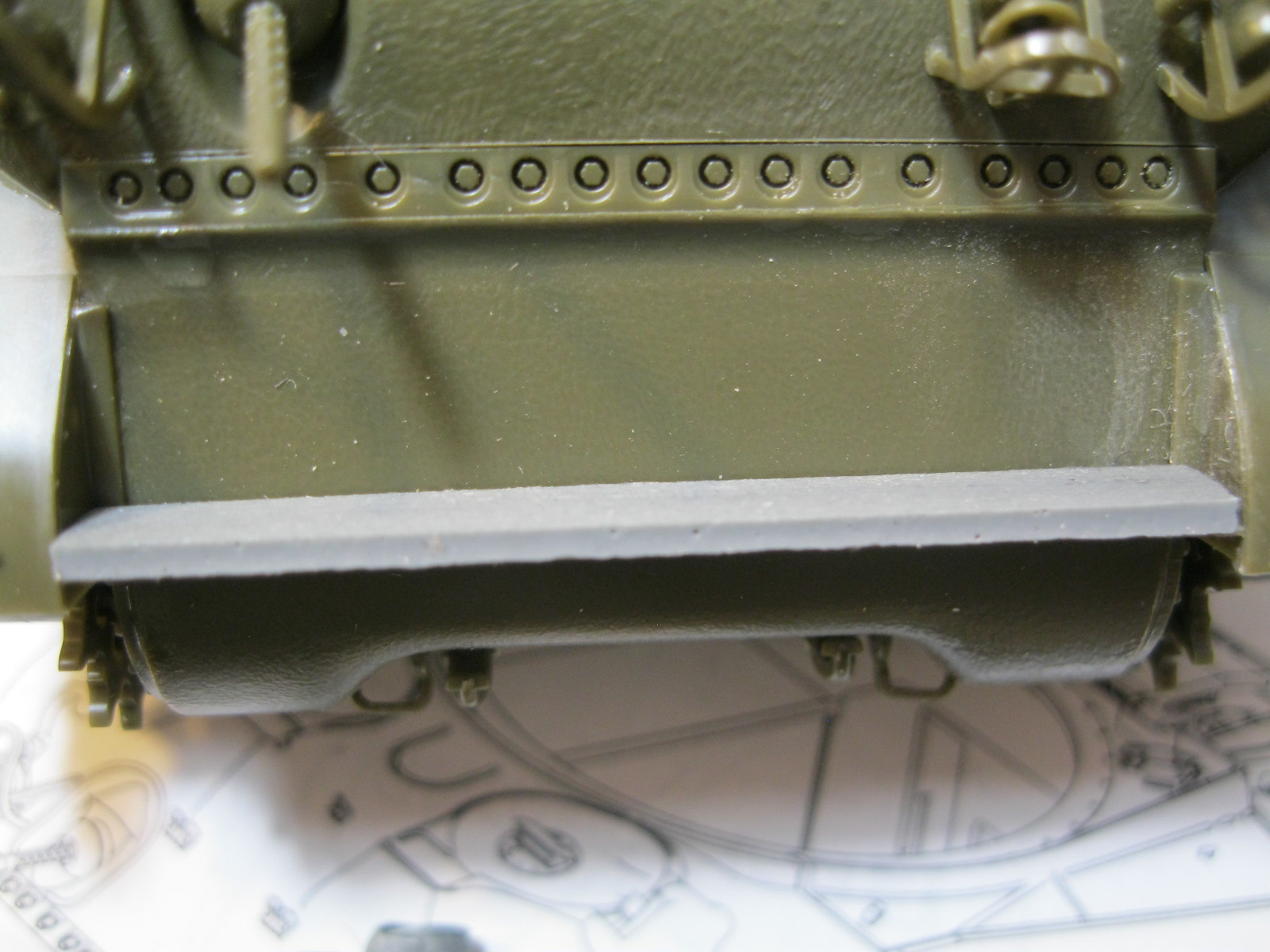

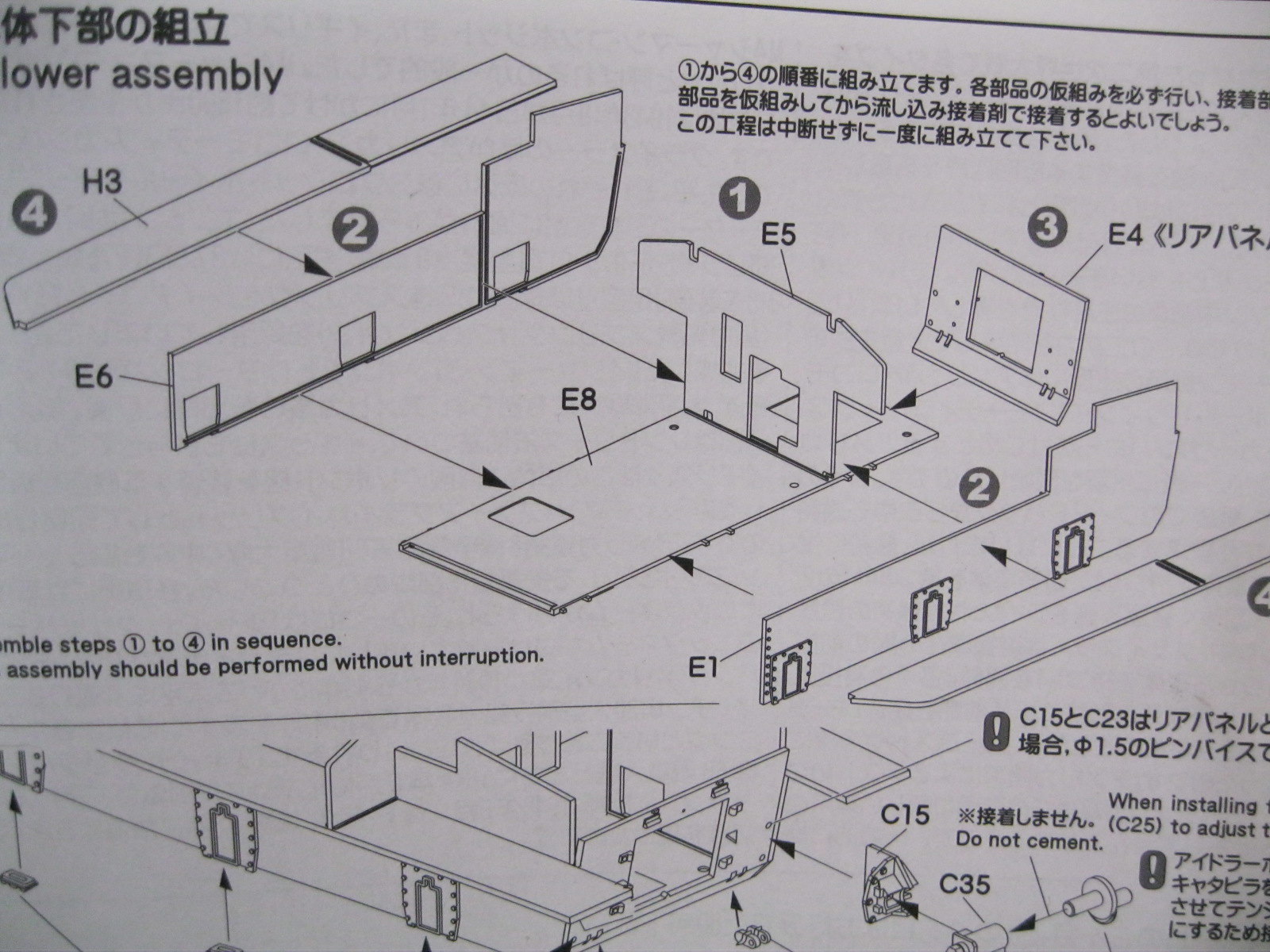

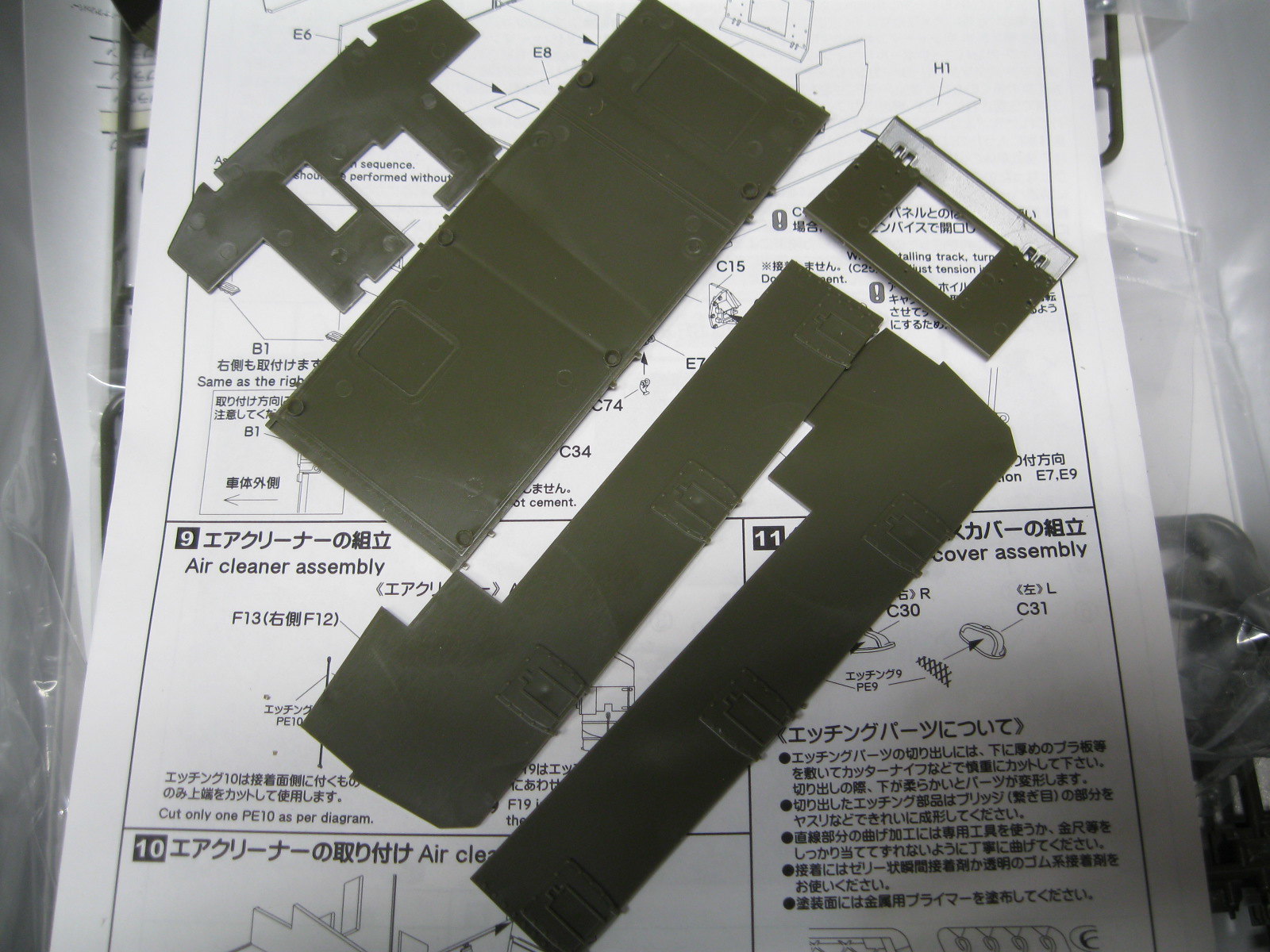

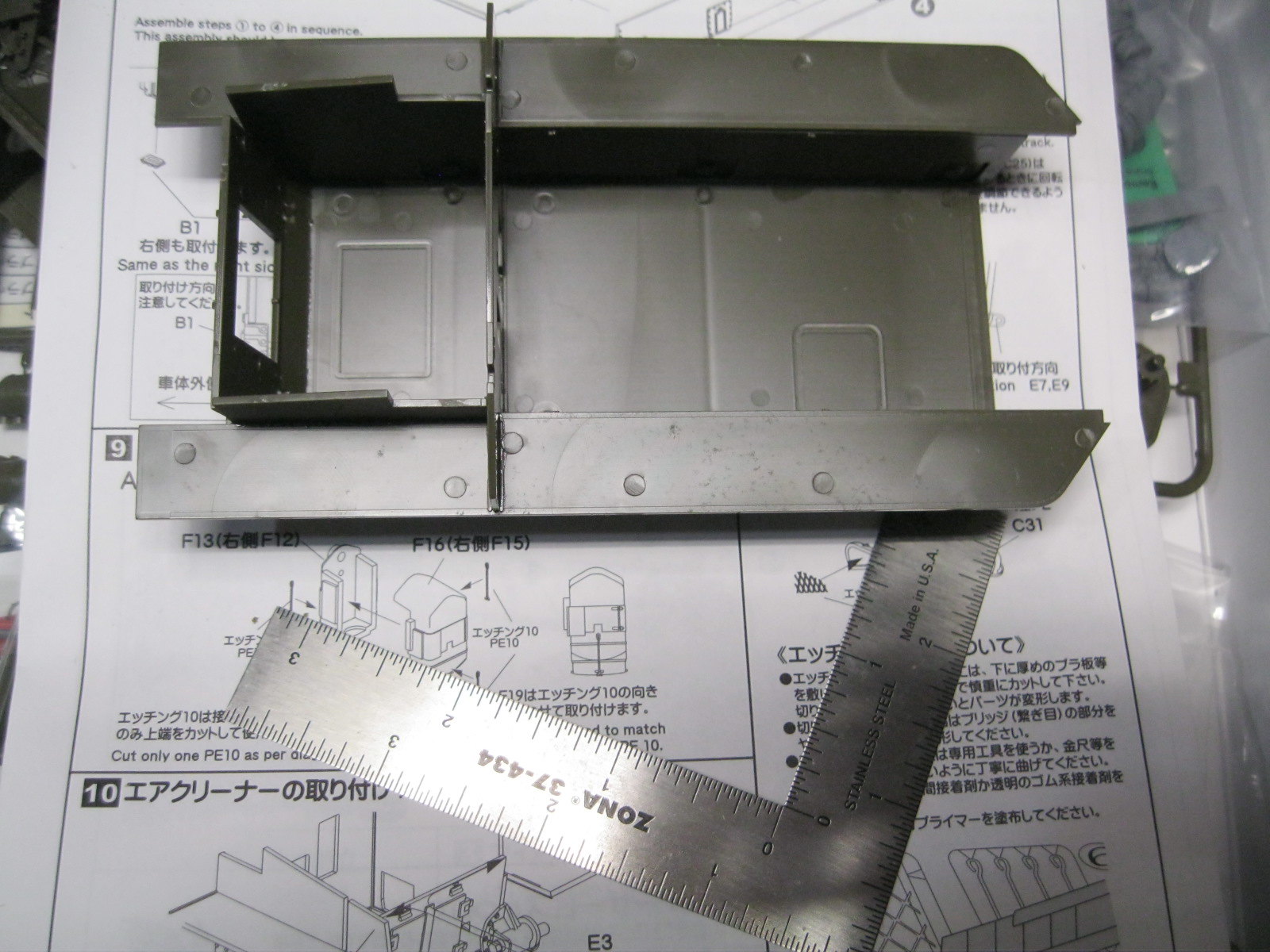

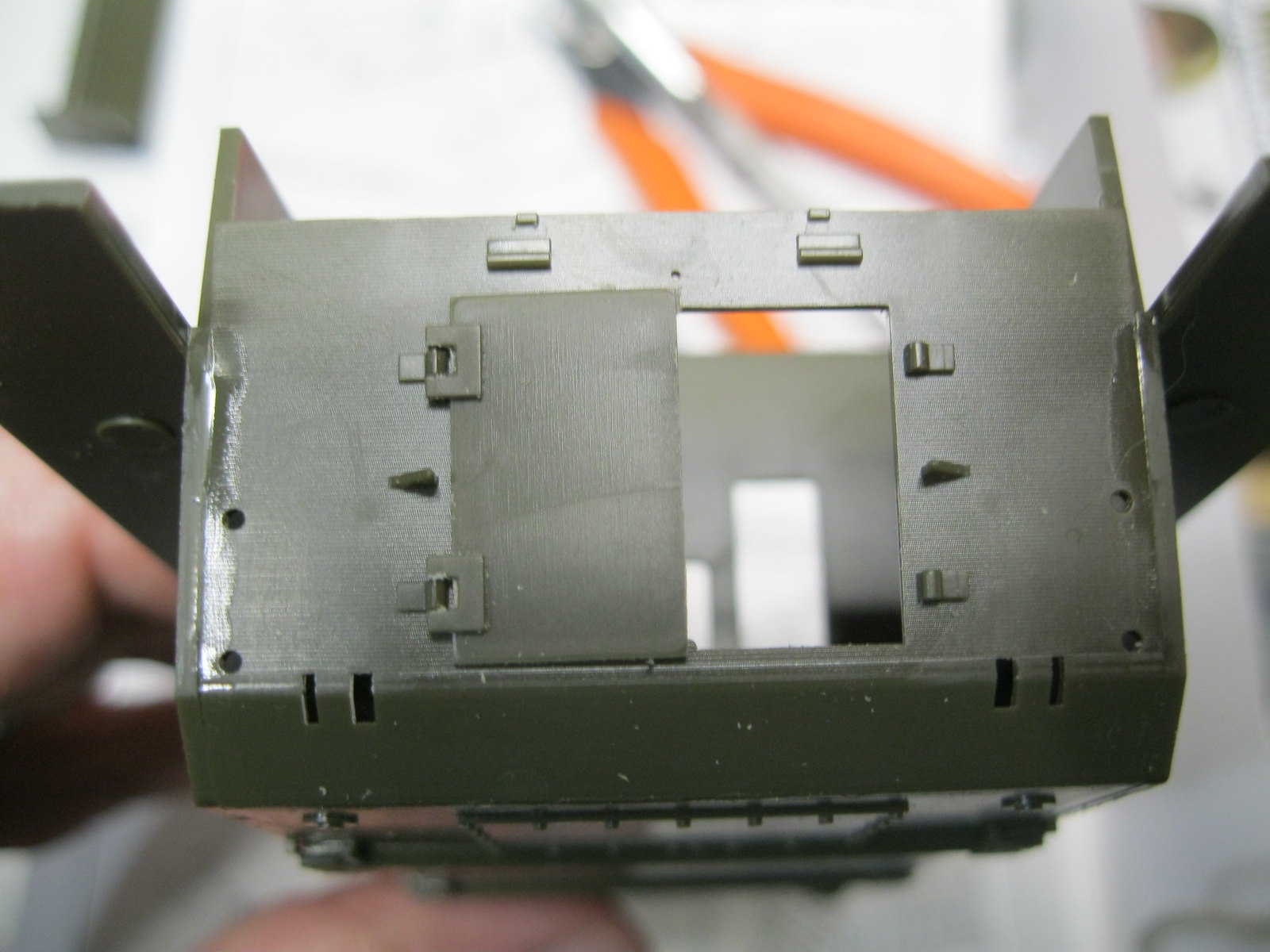

Bigger update today. Starting with the lower hull, I pulled out a small square to make sure everything was lined up properly. The hull parts fit well but are noticeably thinner than the typical molded hull tub. Makes for a better scale effect. It also makes me envious of the guys building all the new German tanks with full interiors. Nothing to show here.

IMG_9651

IMG_9651 by

russell amott, on Flickr

IMG_9653

IMG_9653 by

russell amott, on Flickr

IMG_9655

IMG_9655 by

russell amott, on Flickr

IMG_9656

IMG_9656 by

russell amott, on Flickr

IMG_9657

IMG_9657 by

russell amott, on Flickr

IMG_9658

IMG_9658 by

russell amott, on Flickr

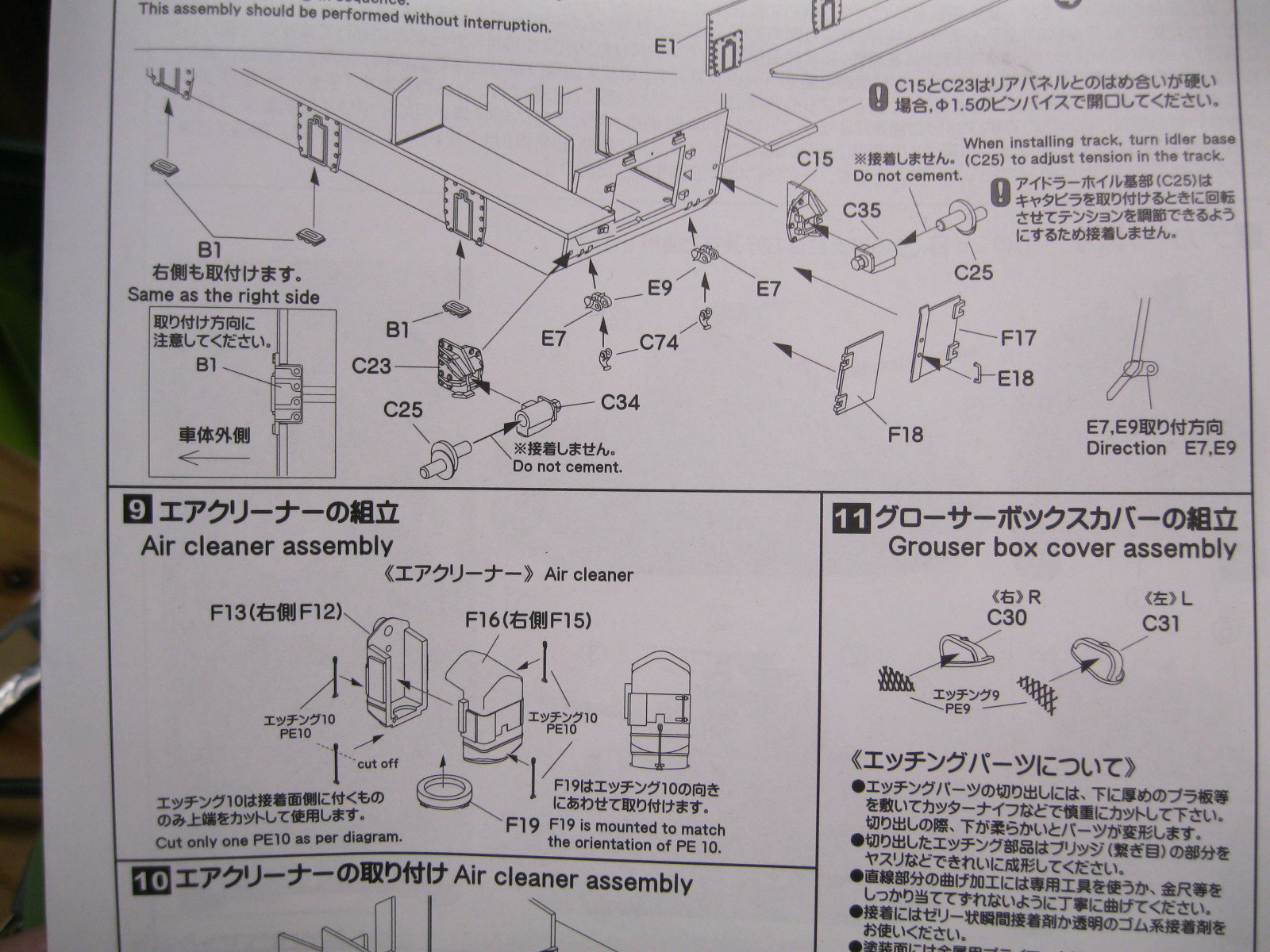

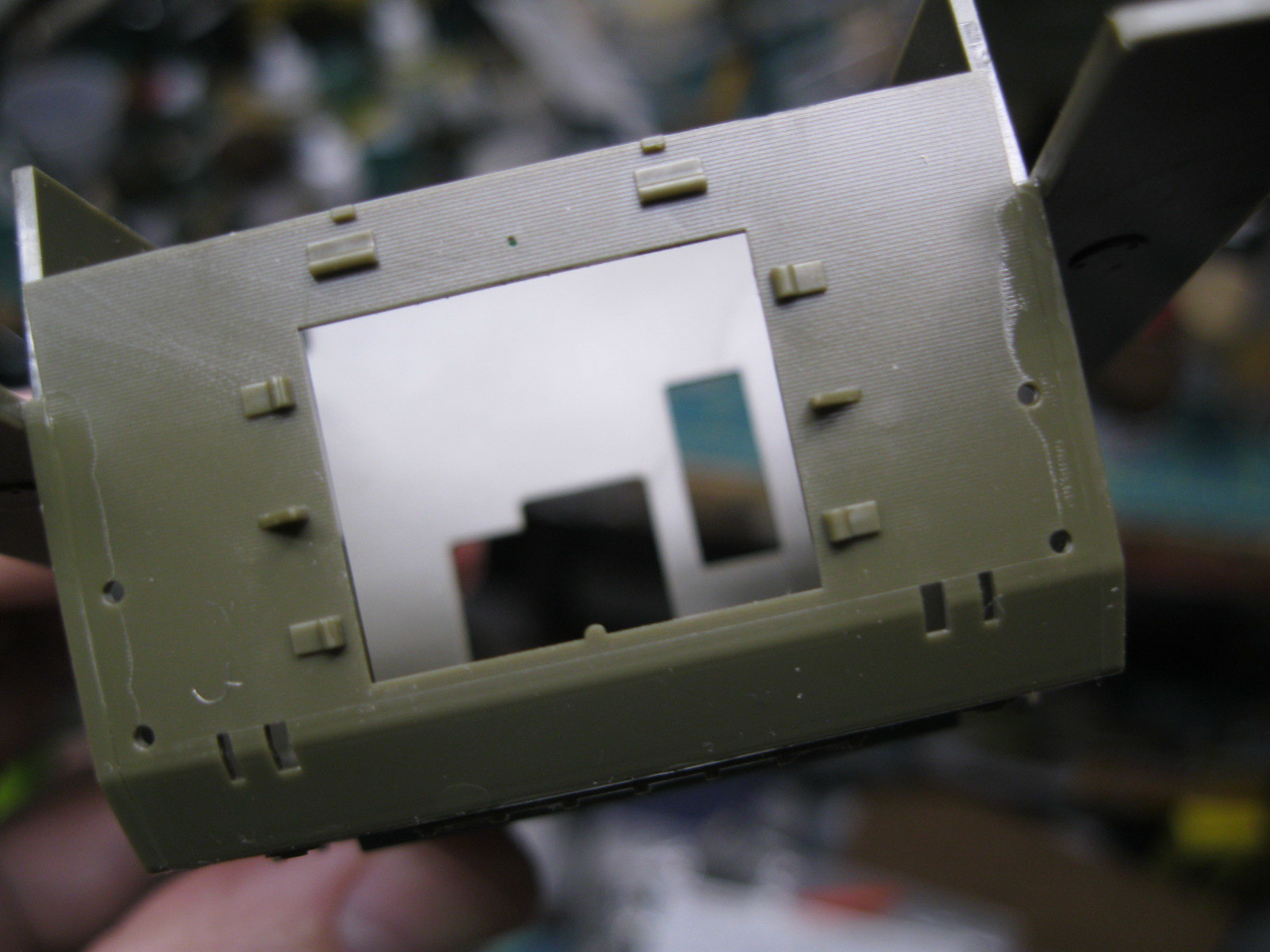

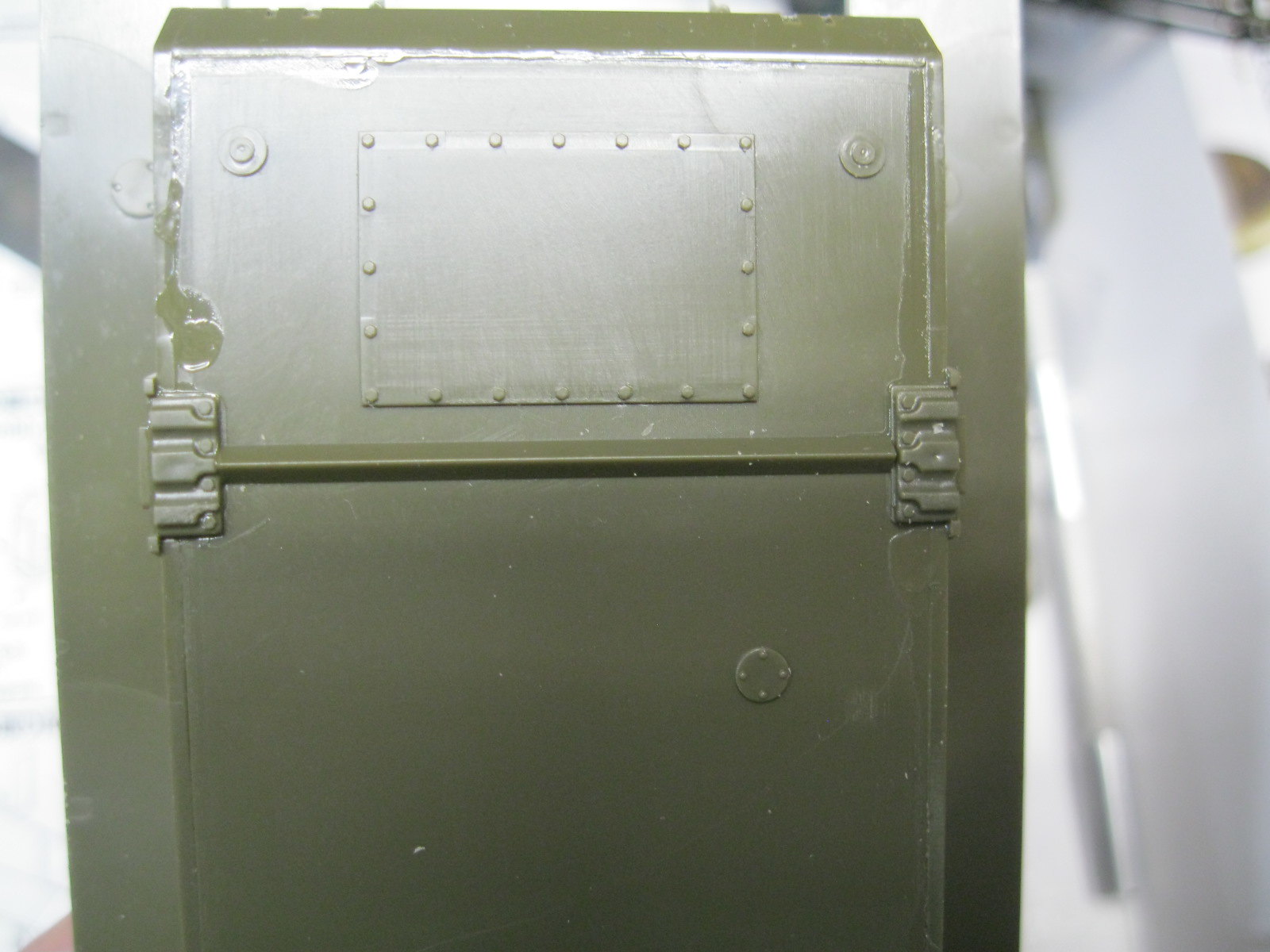

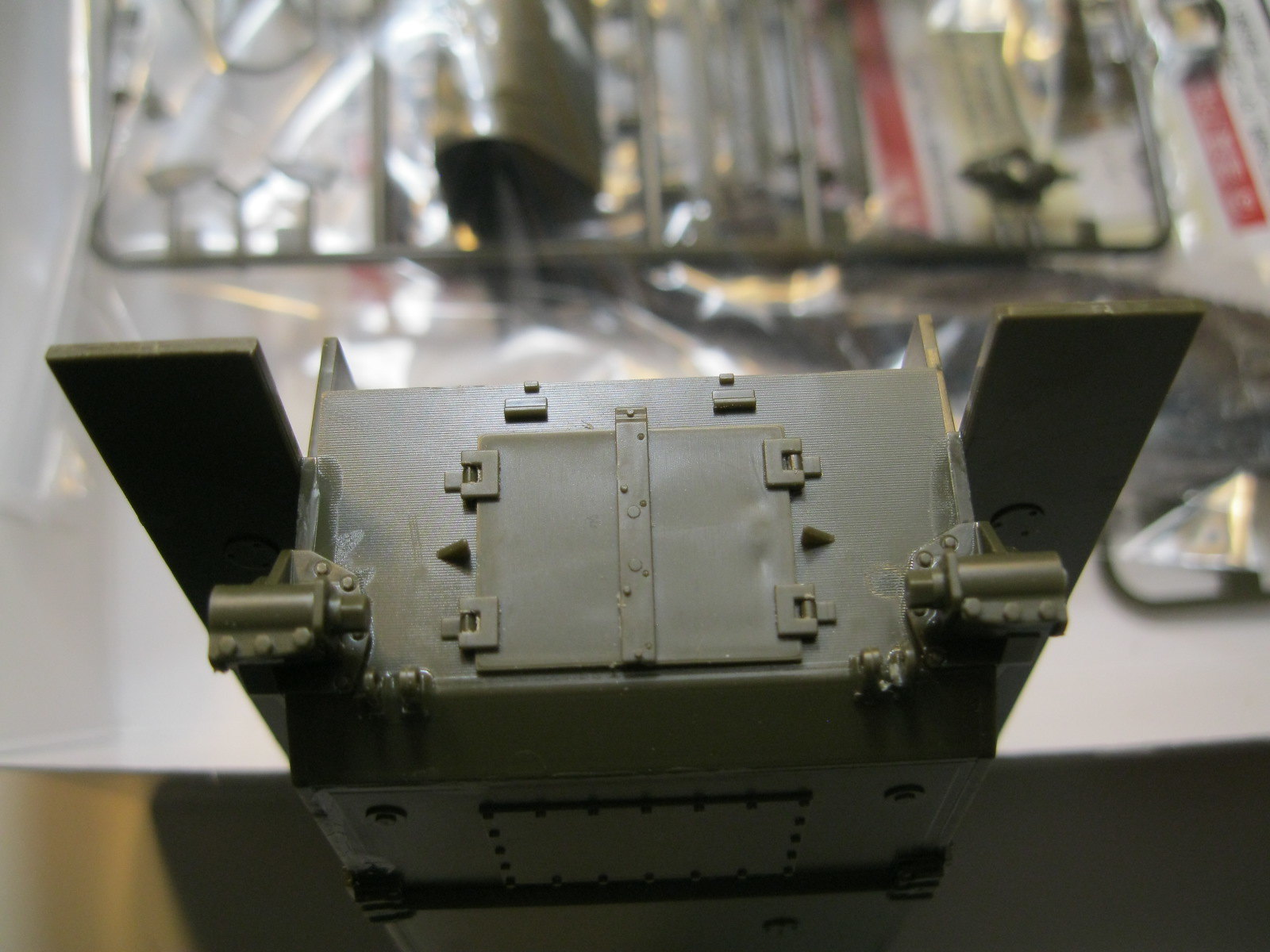

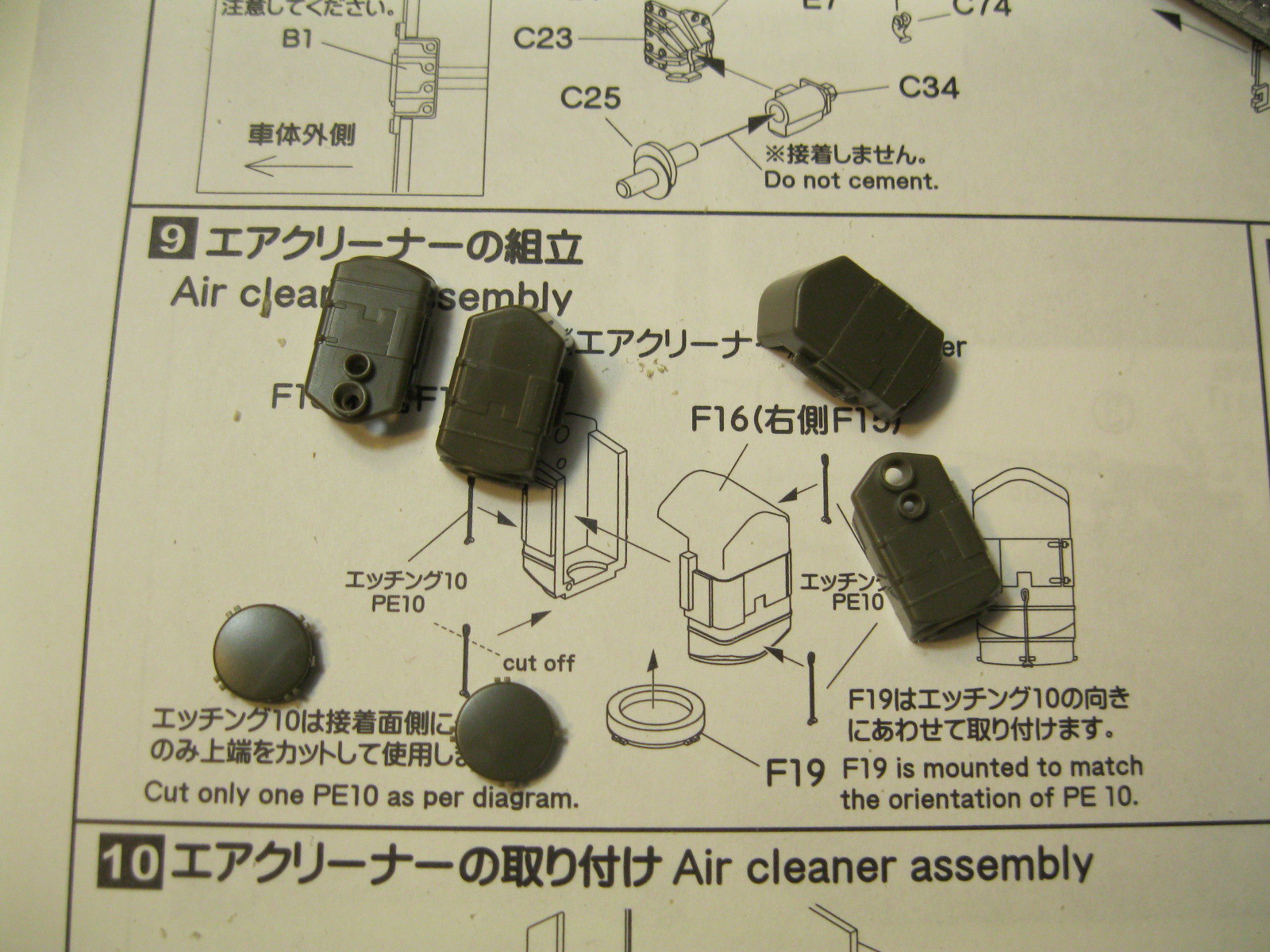

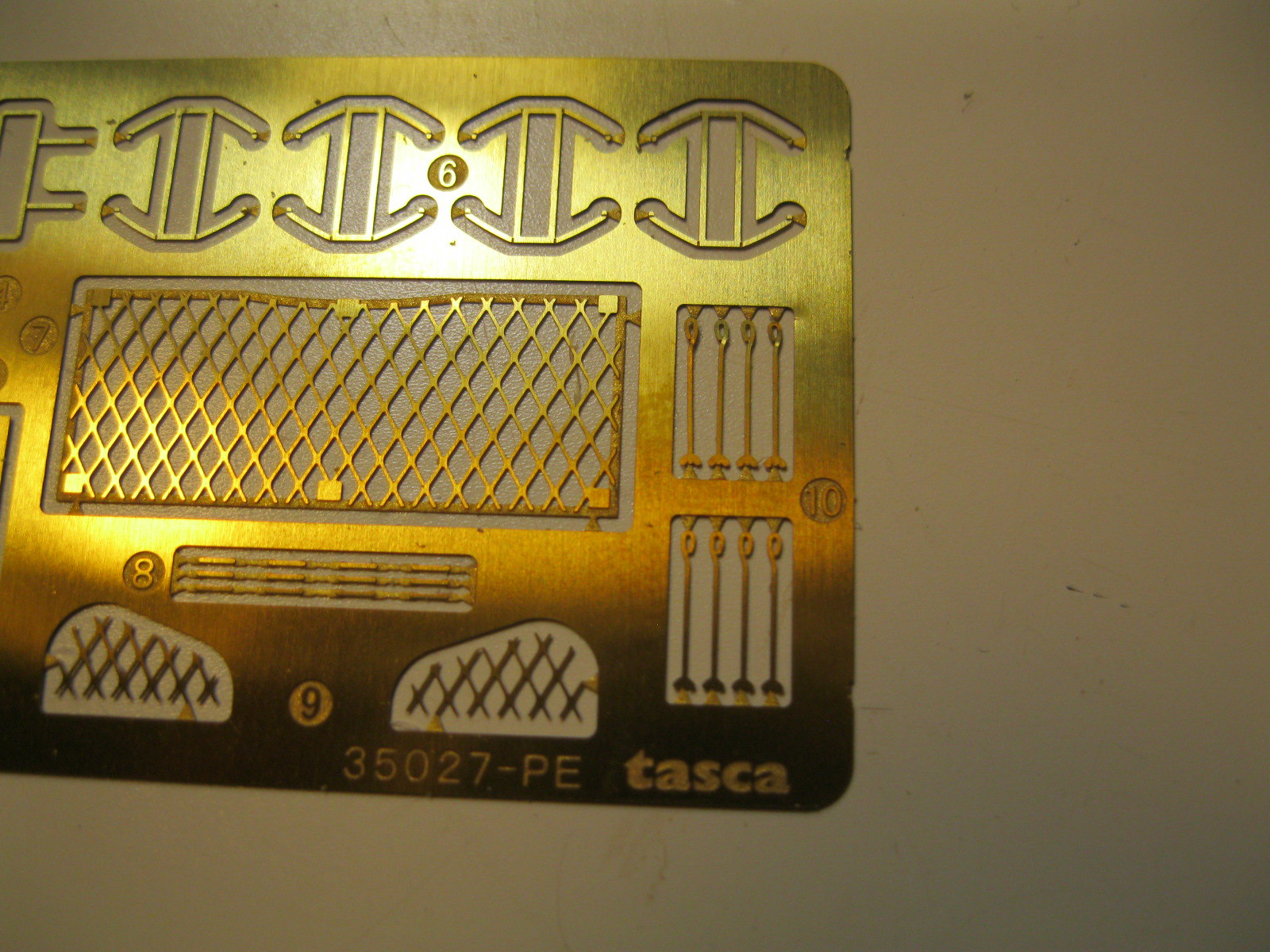

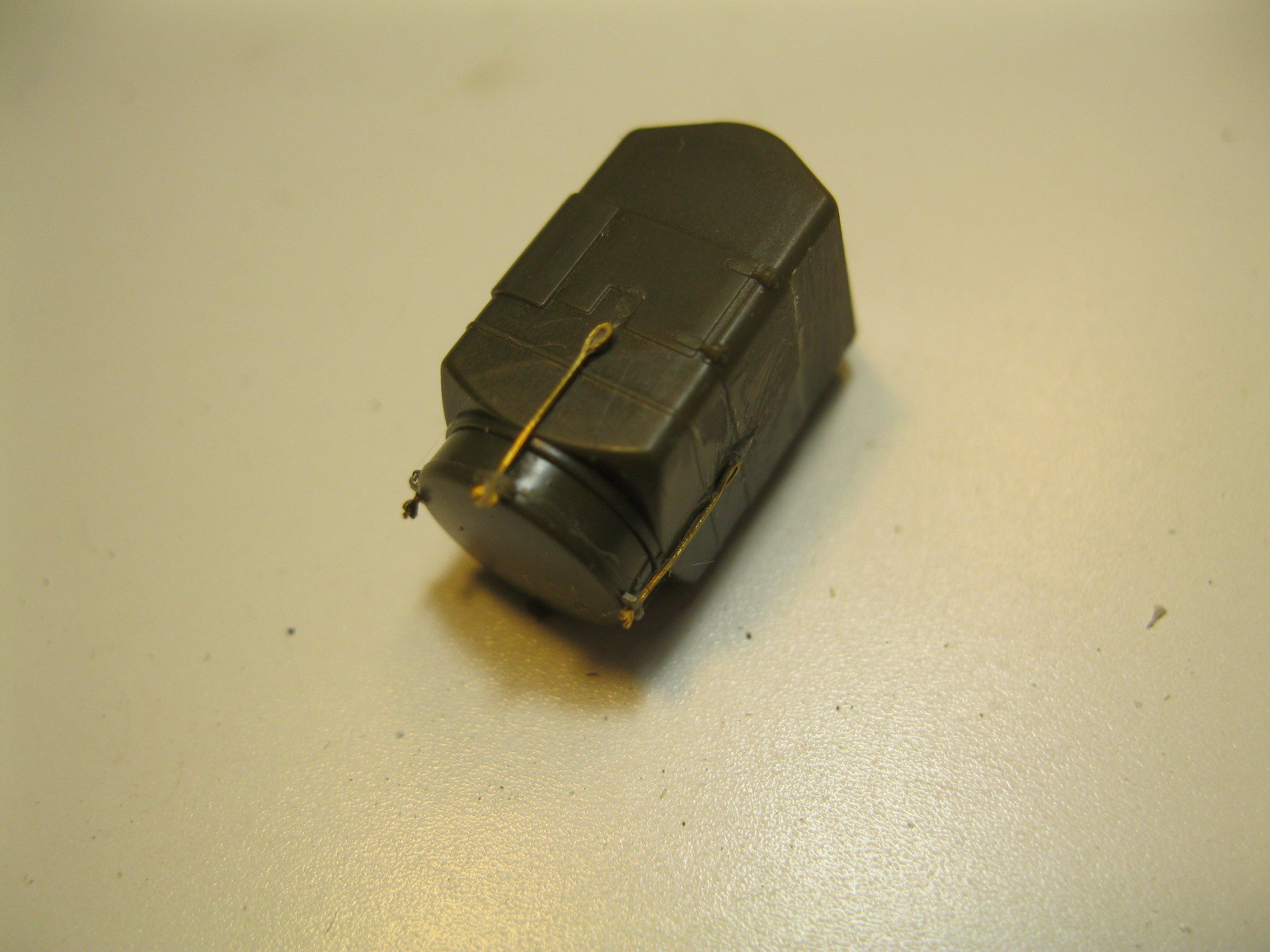

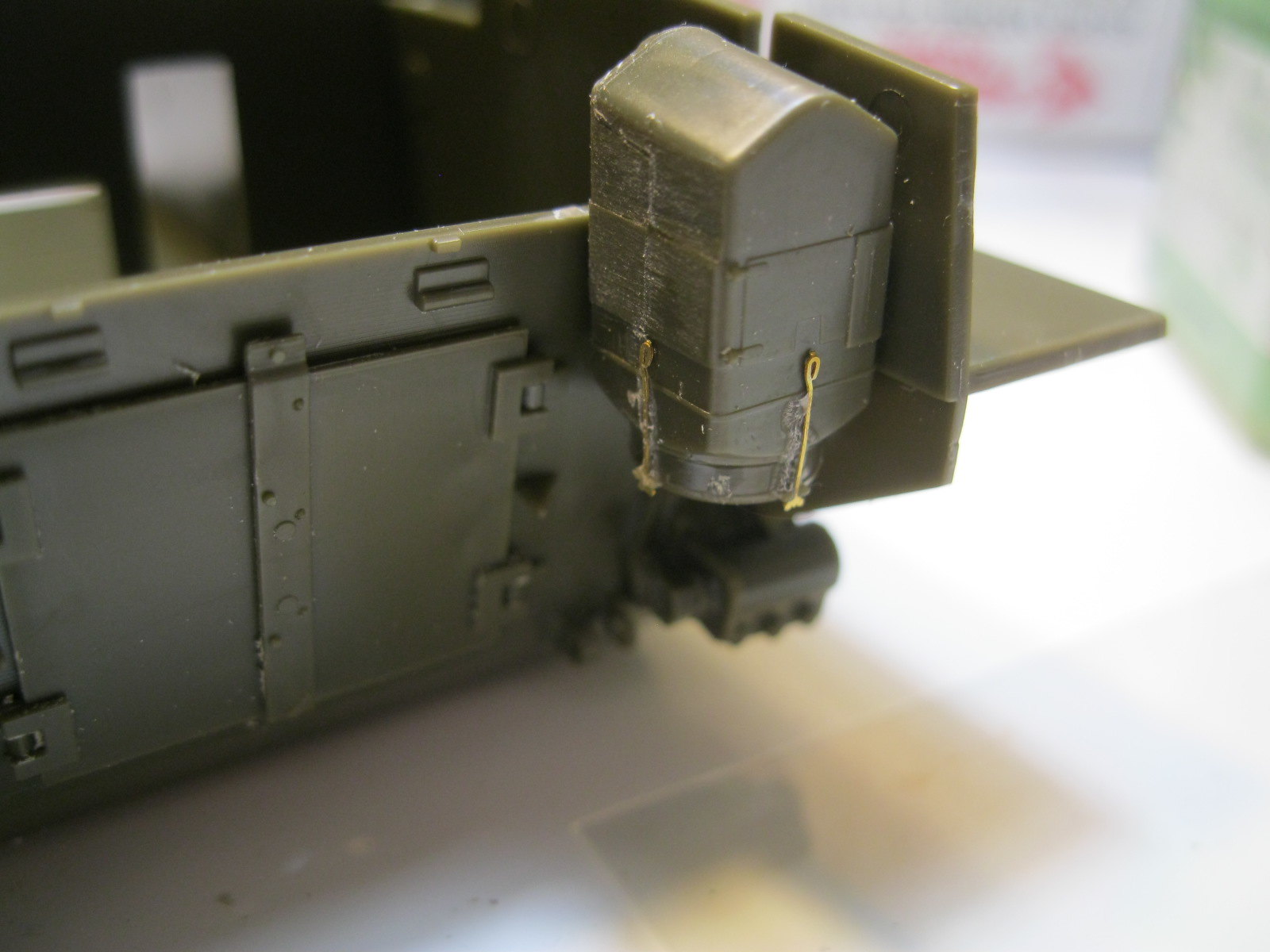

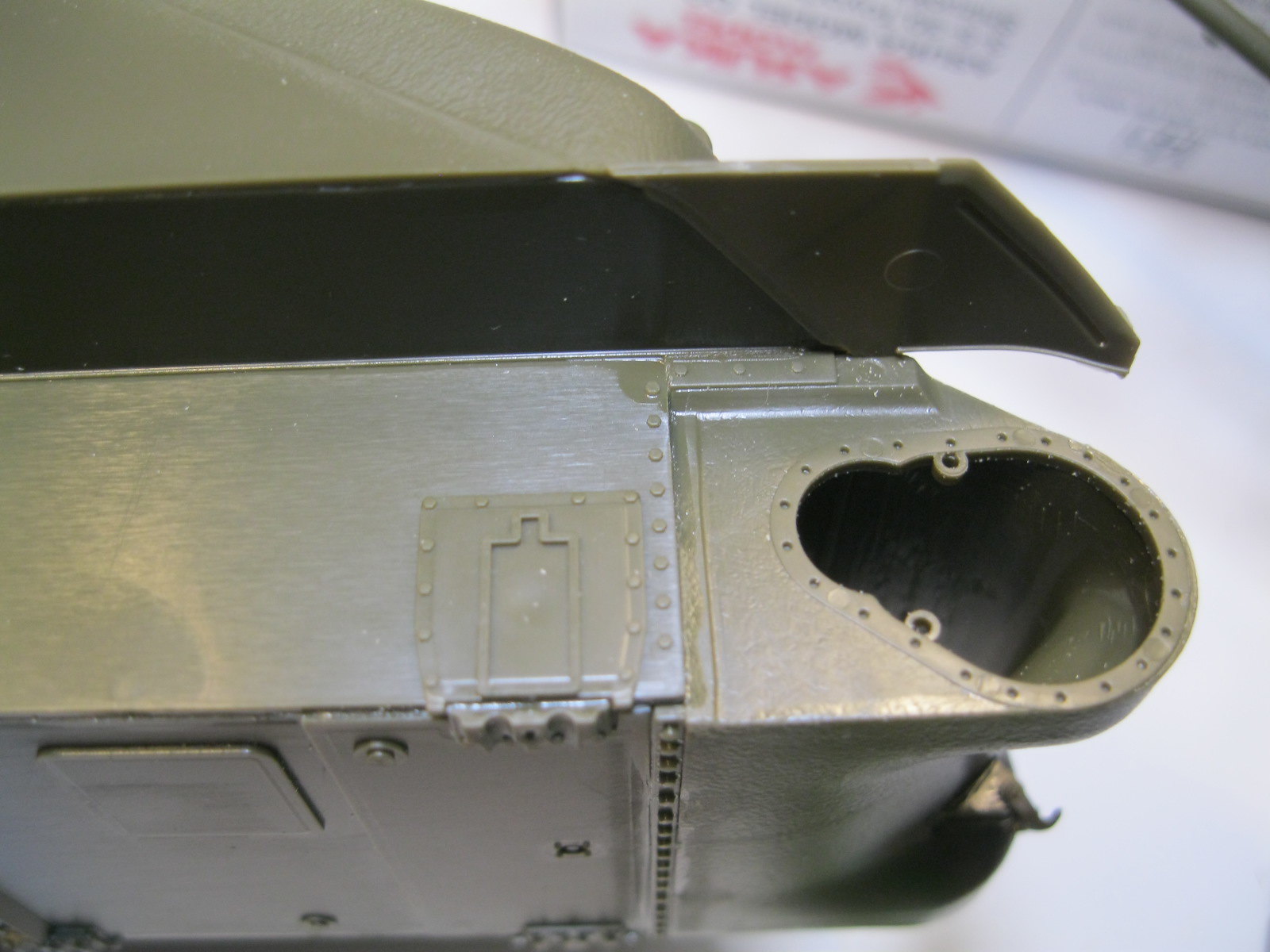

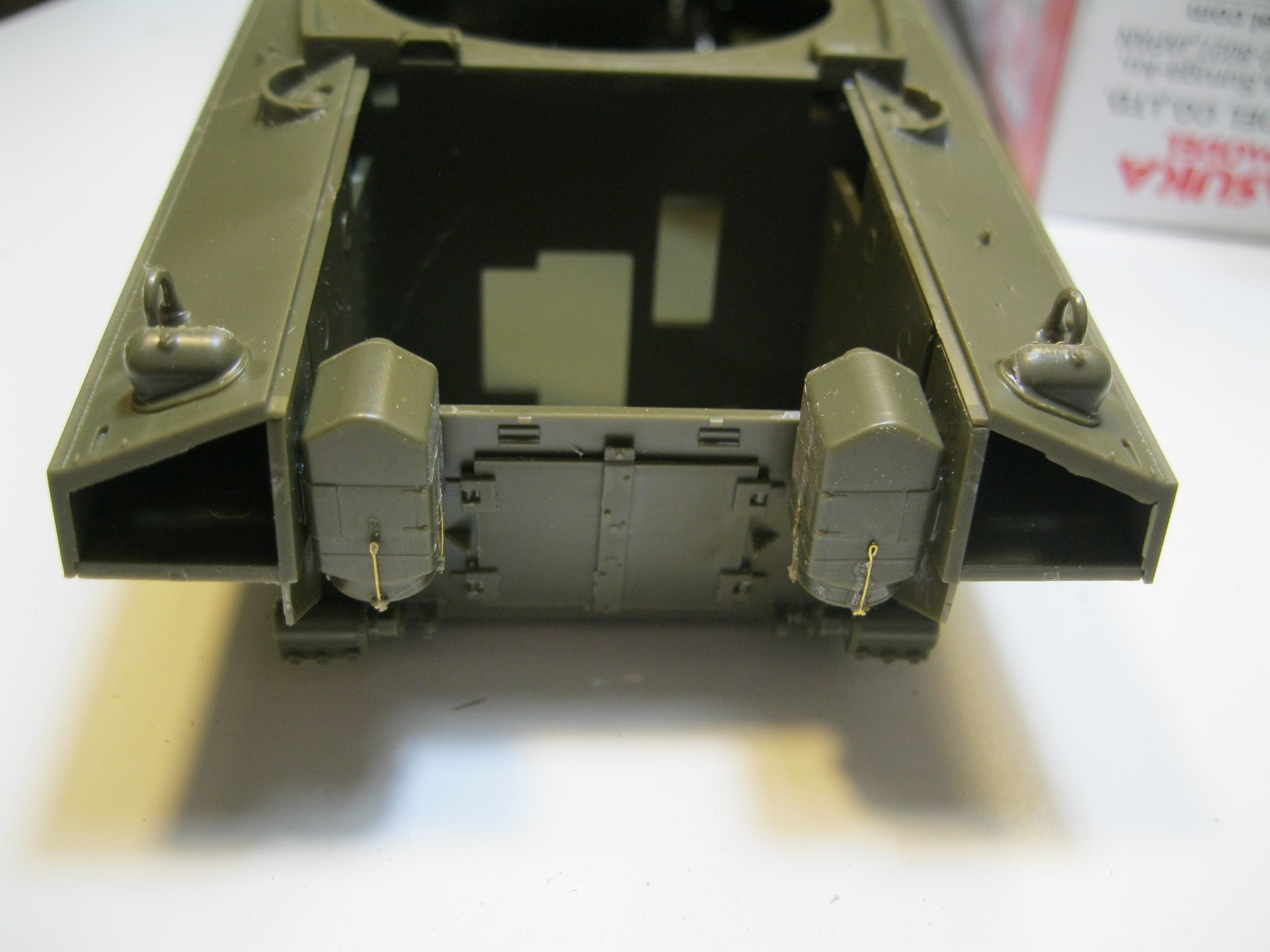

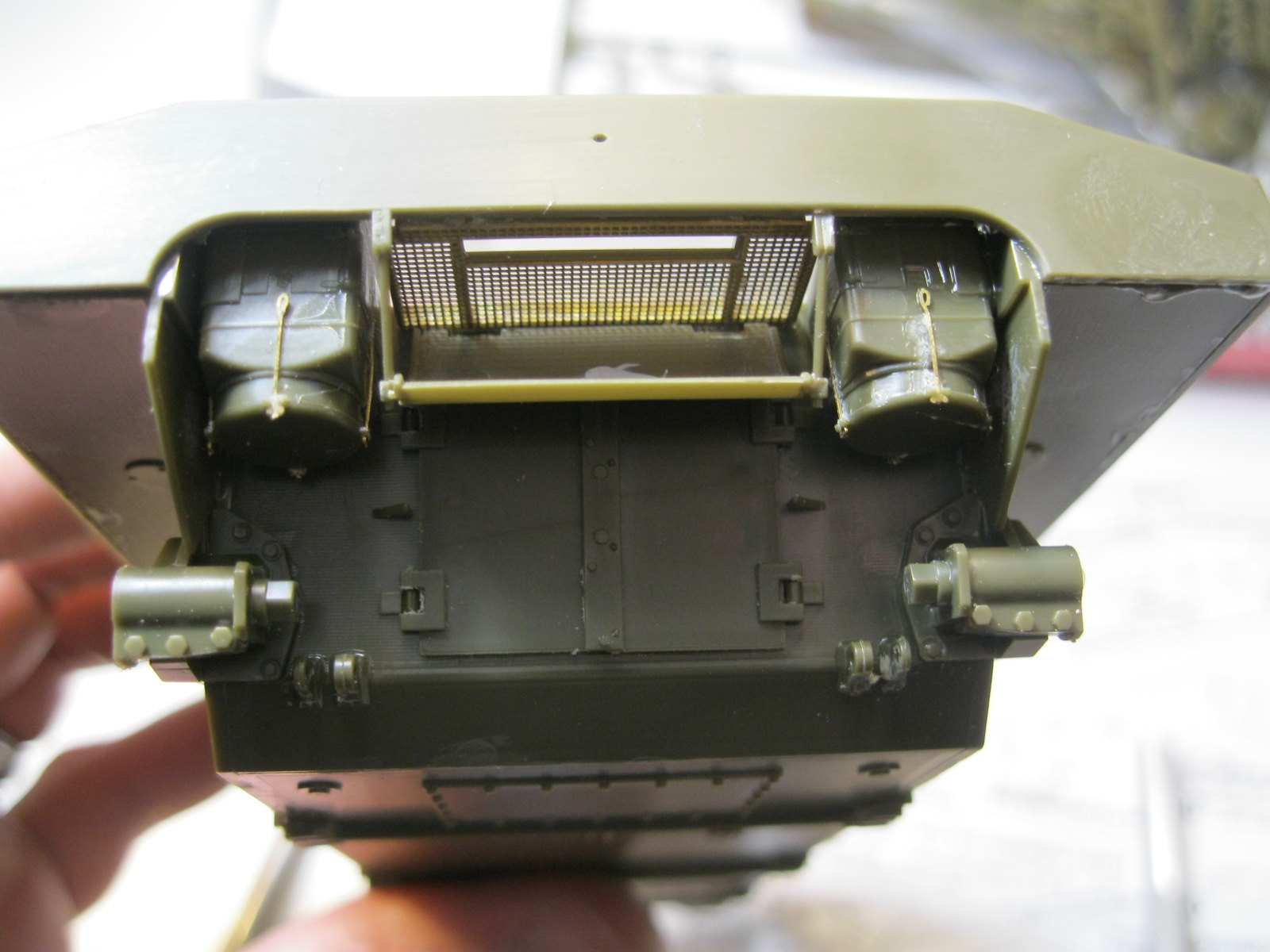

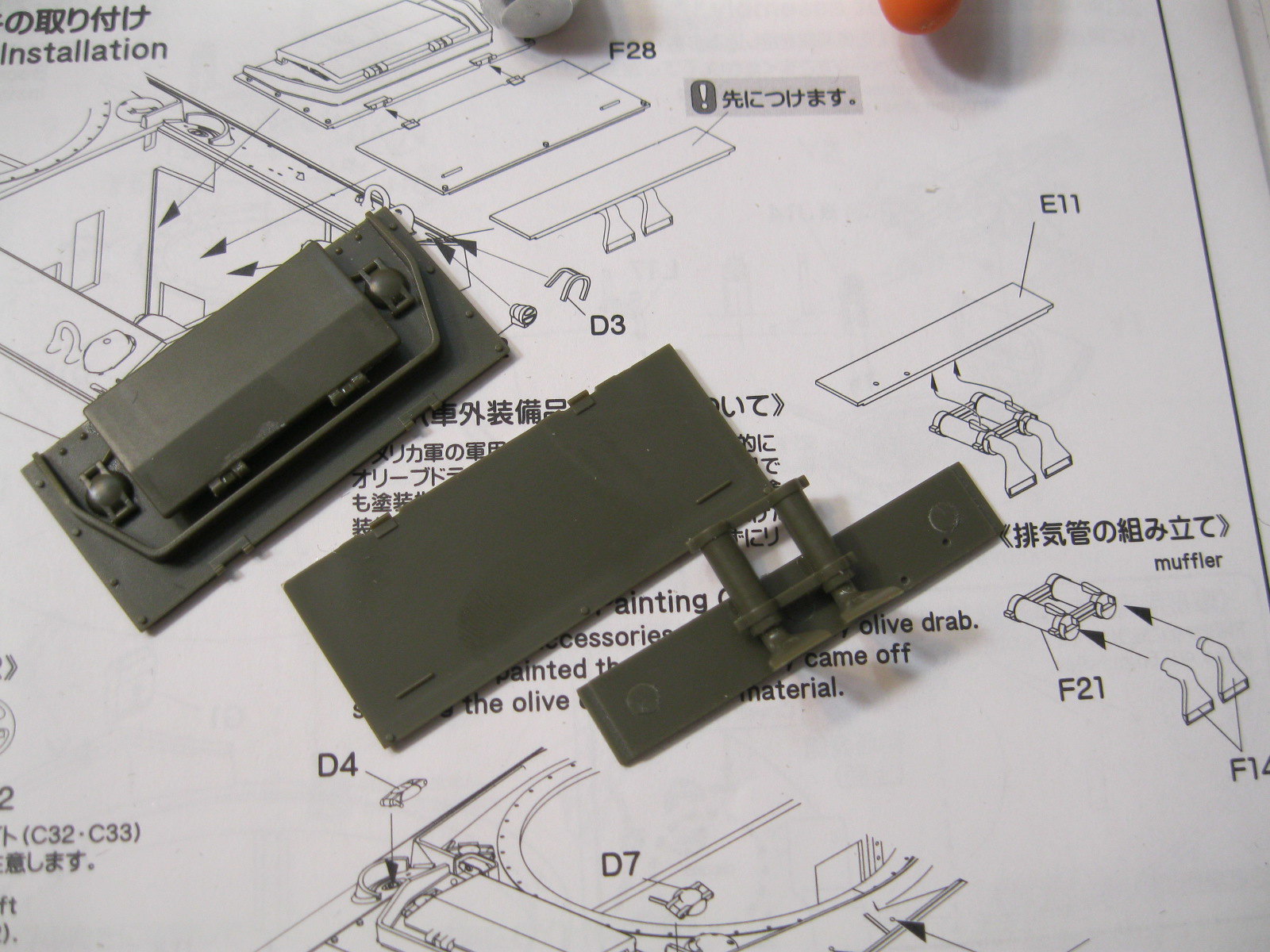

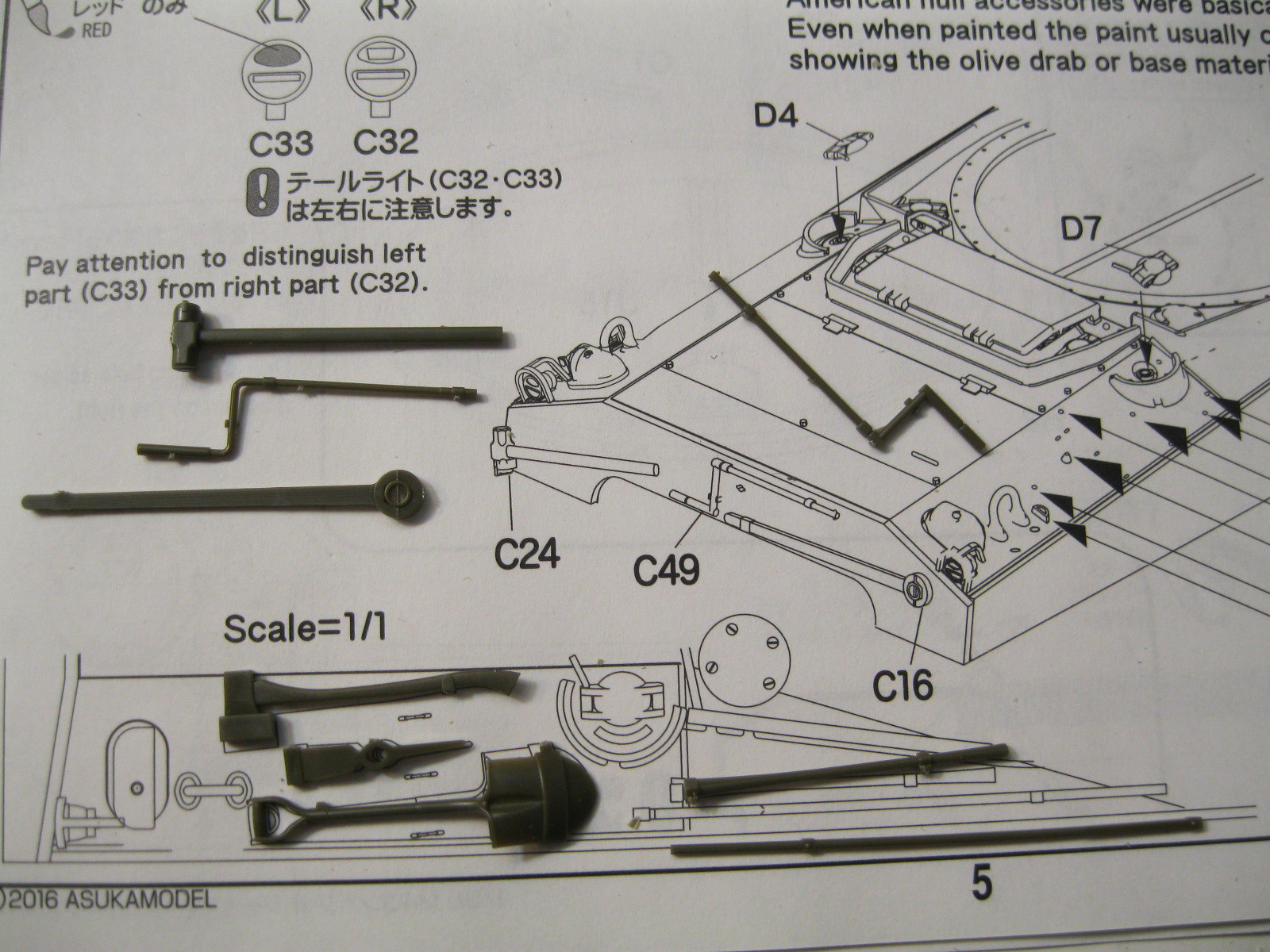

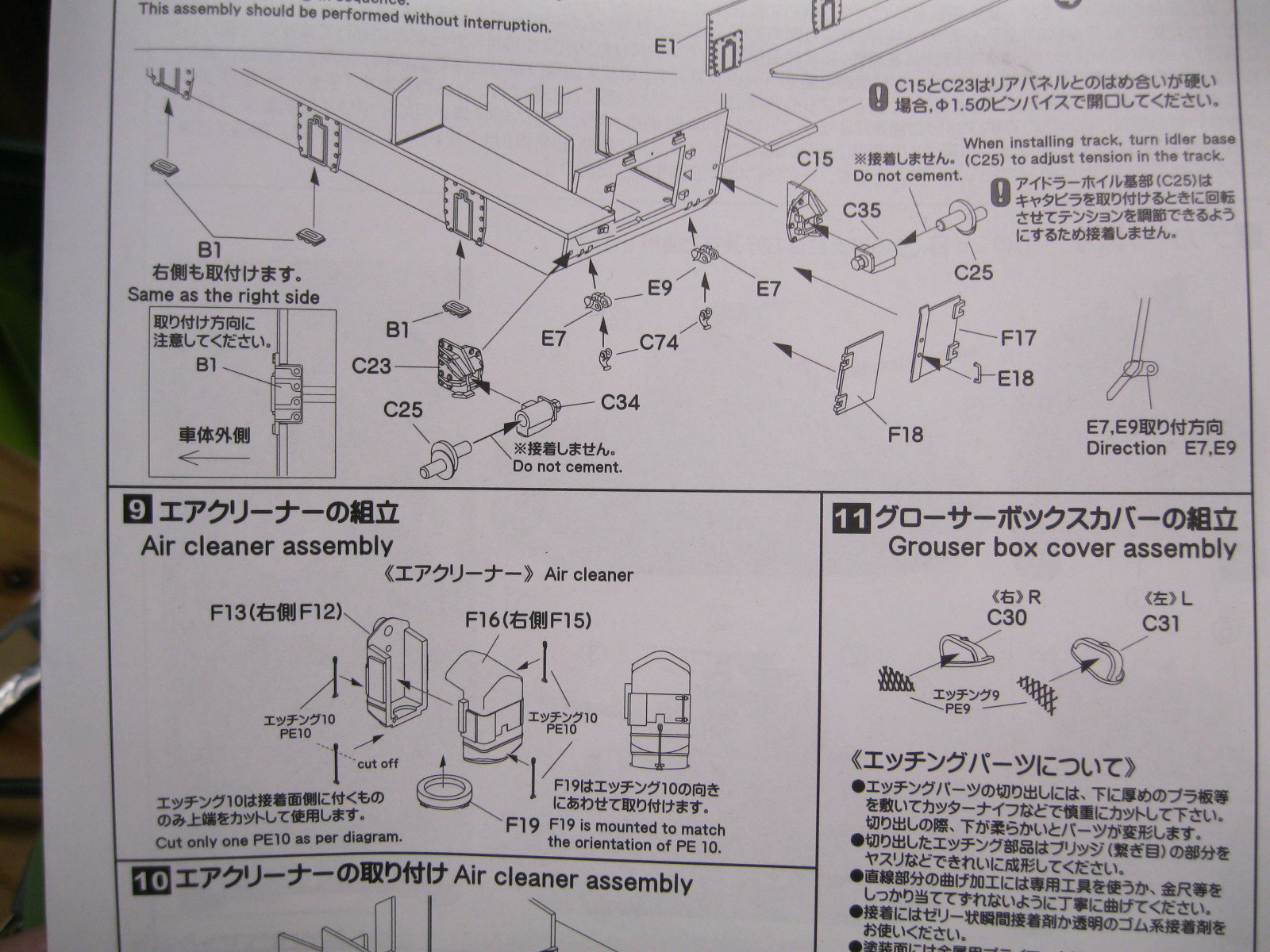

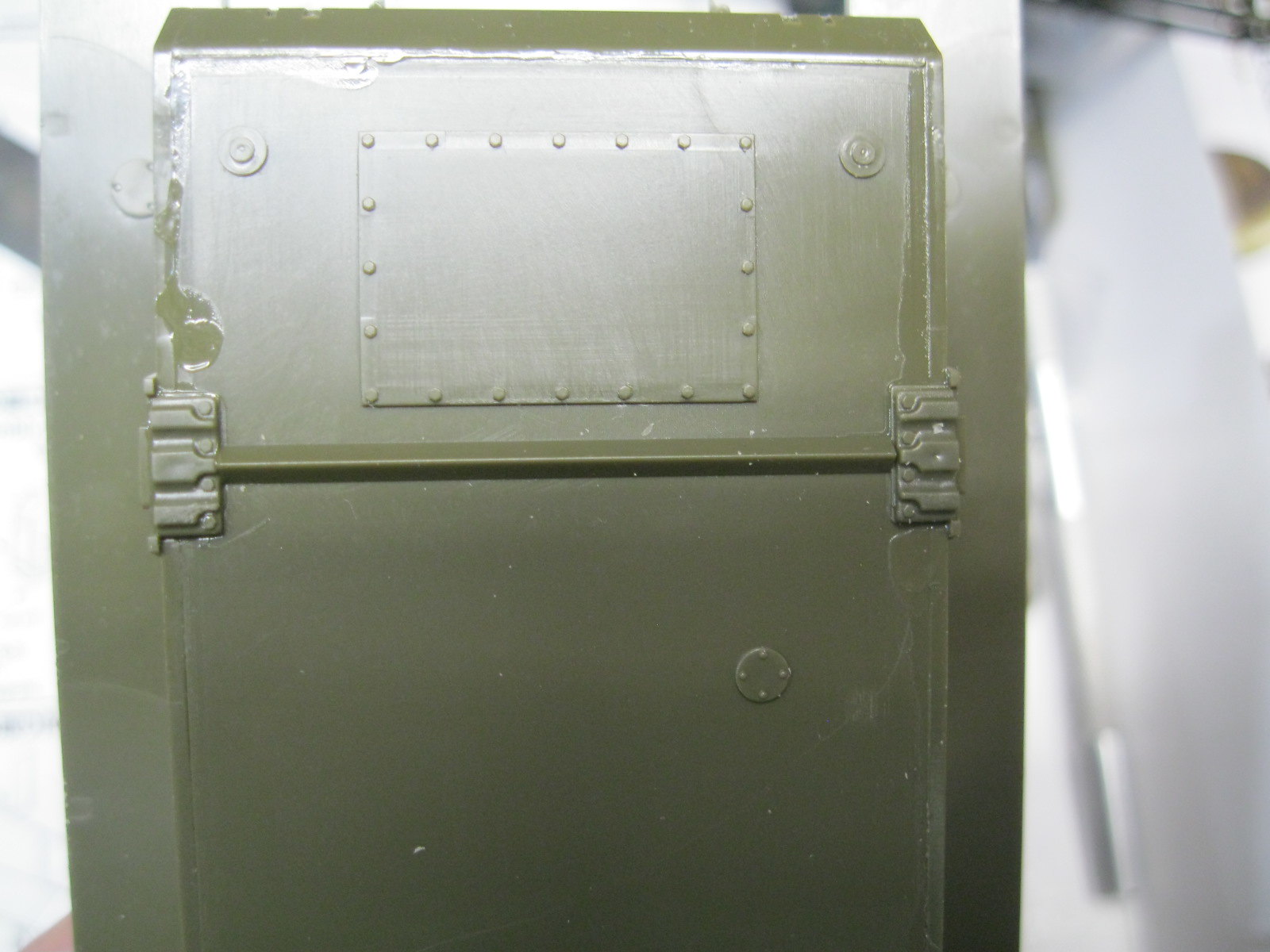

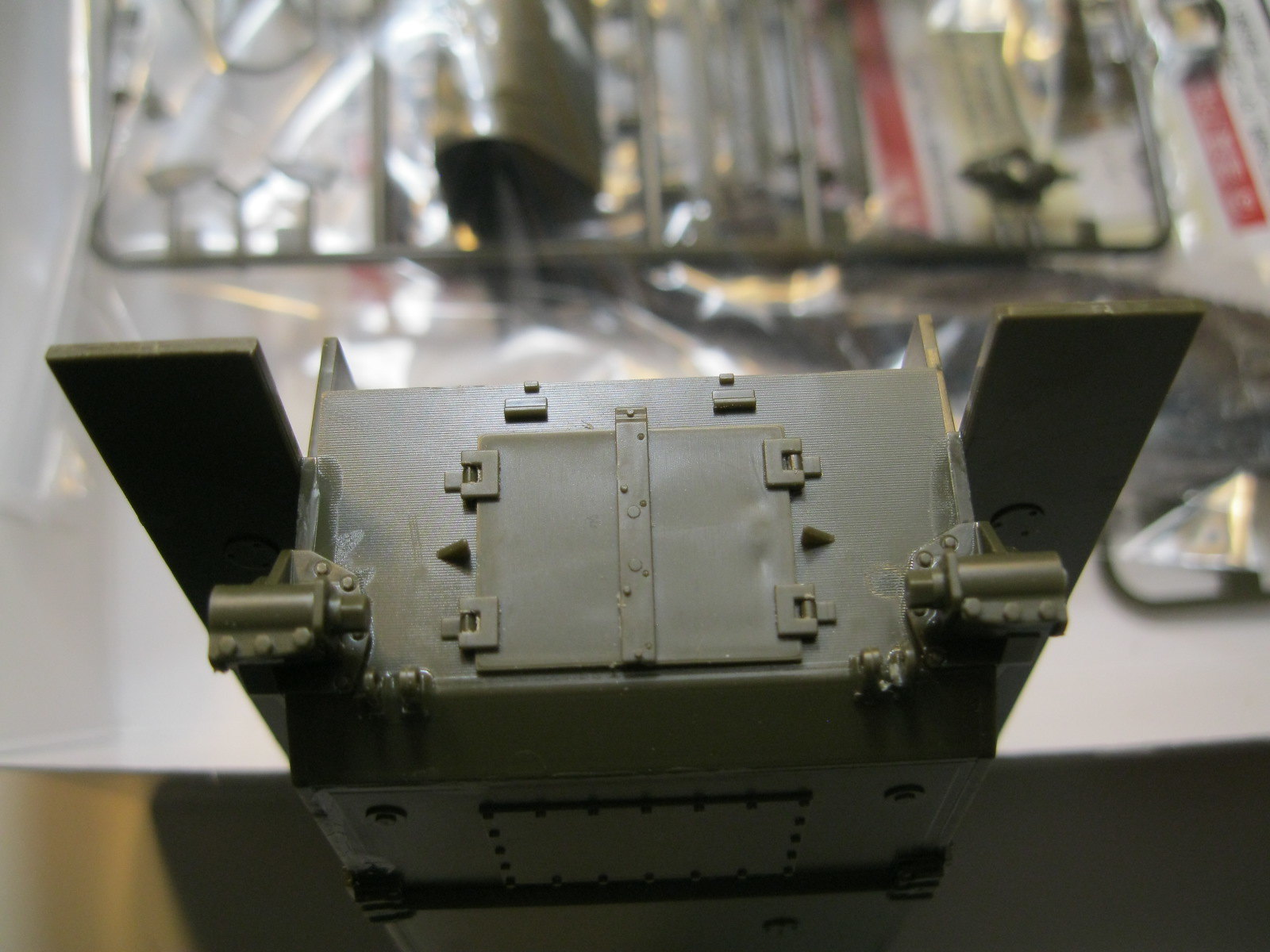

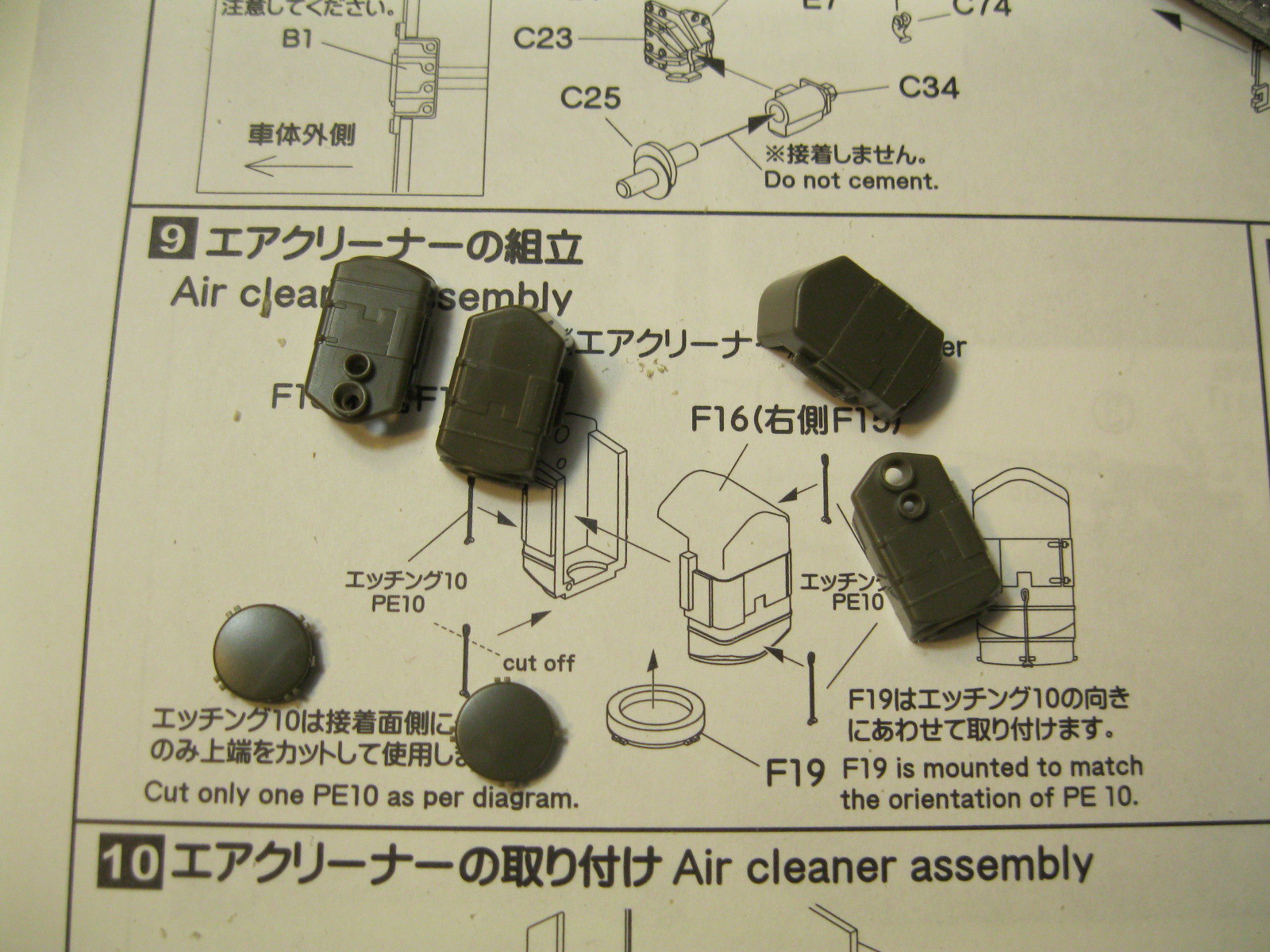

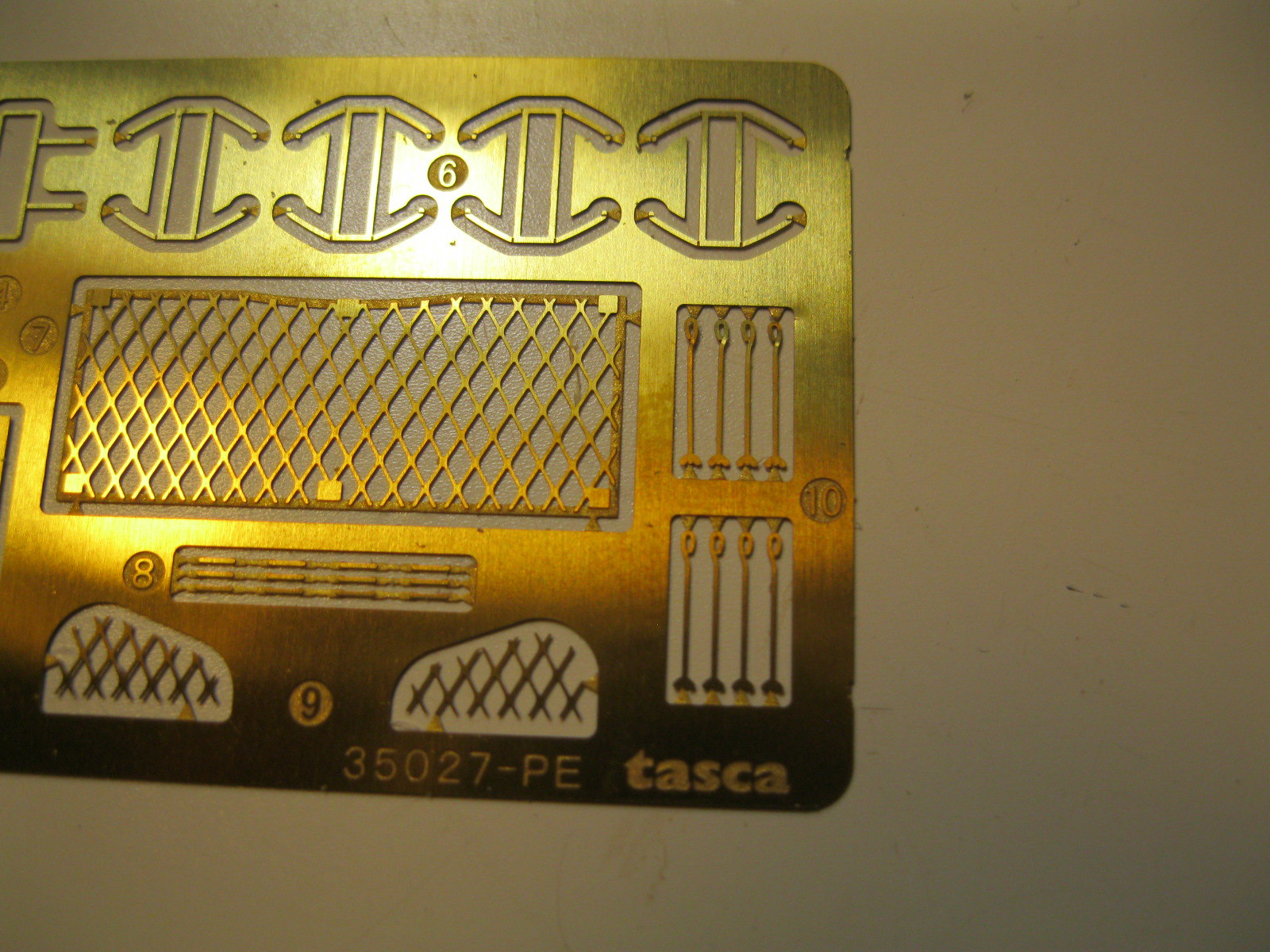

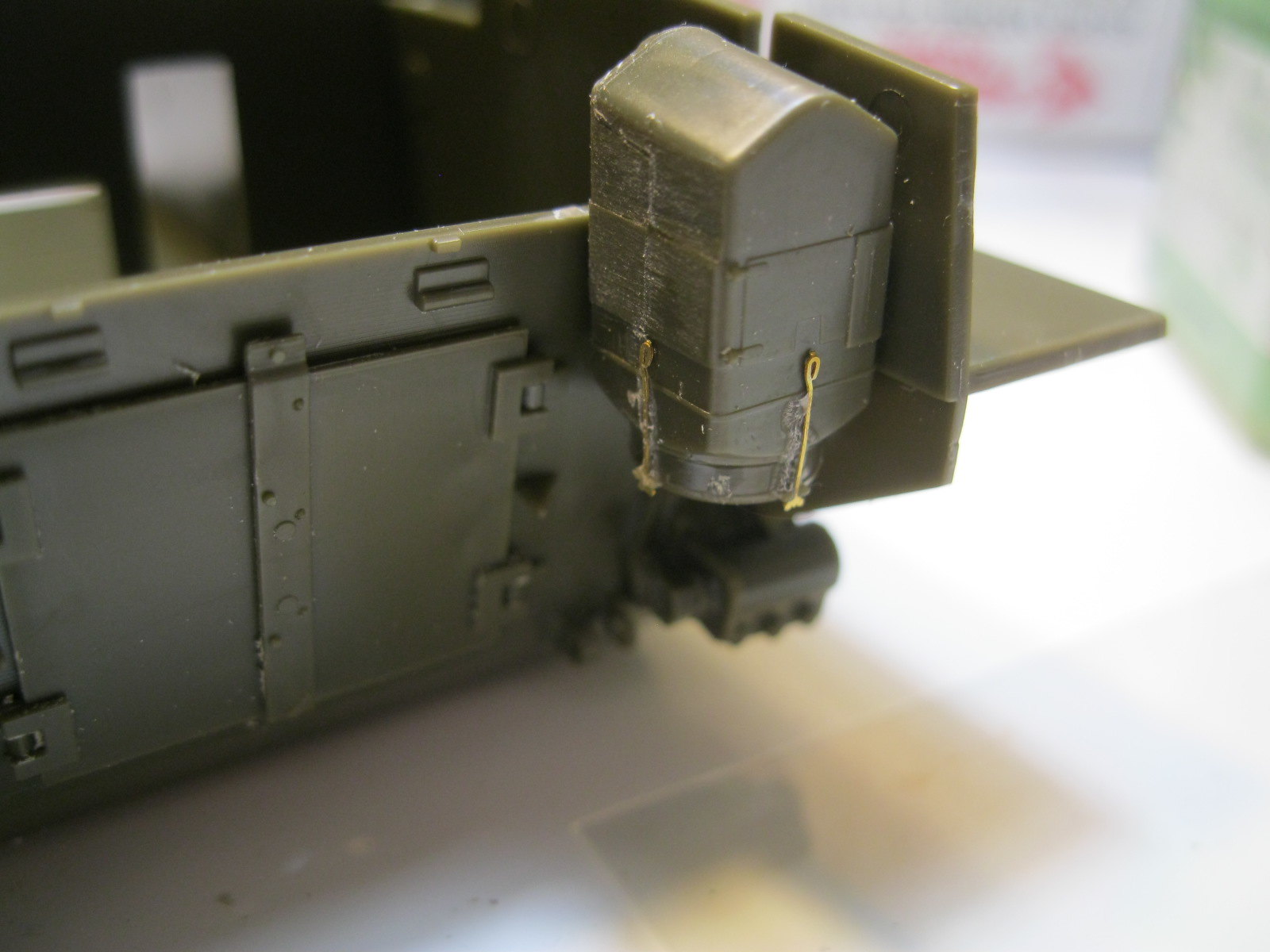

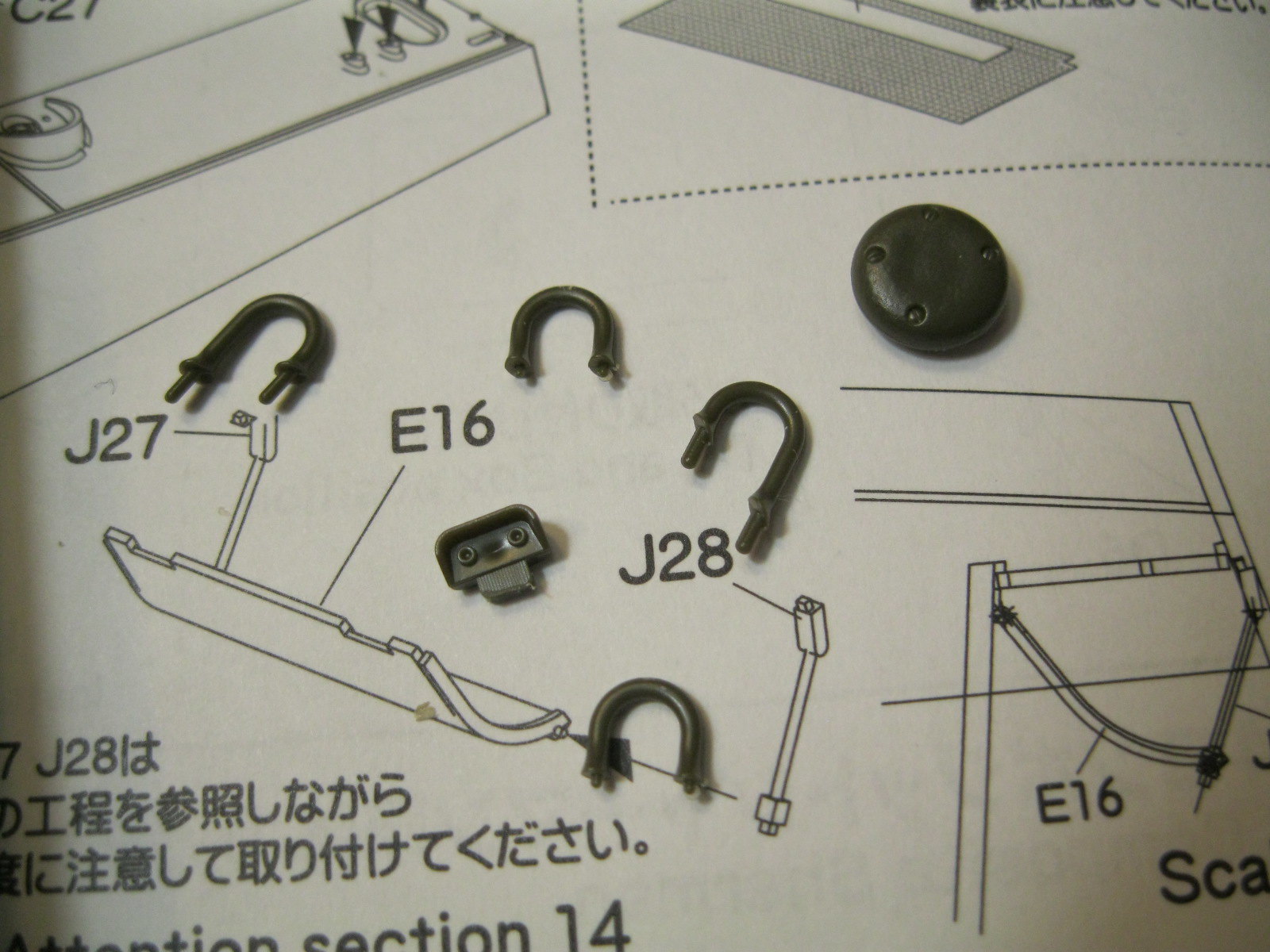

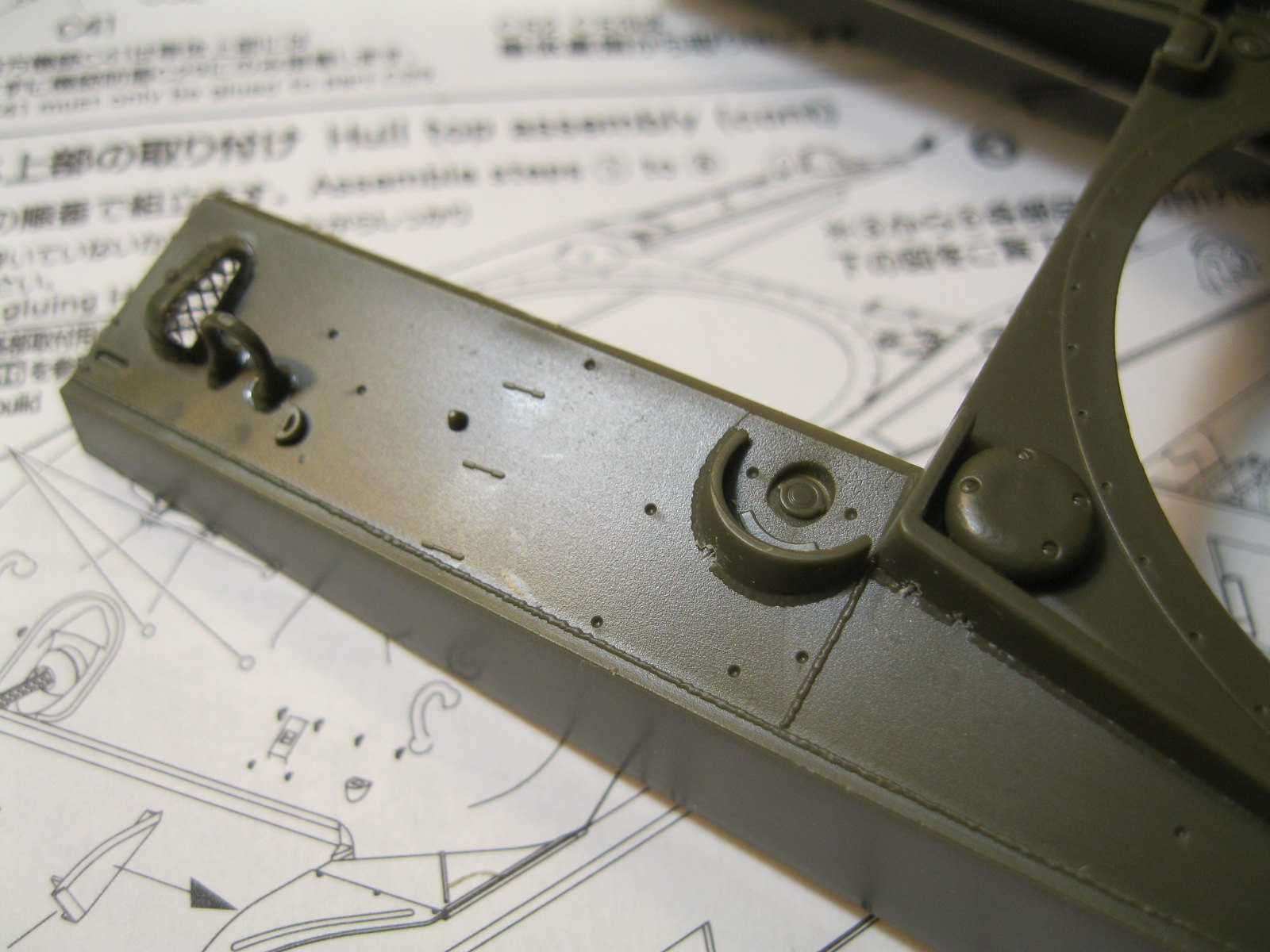

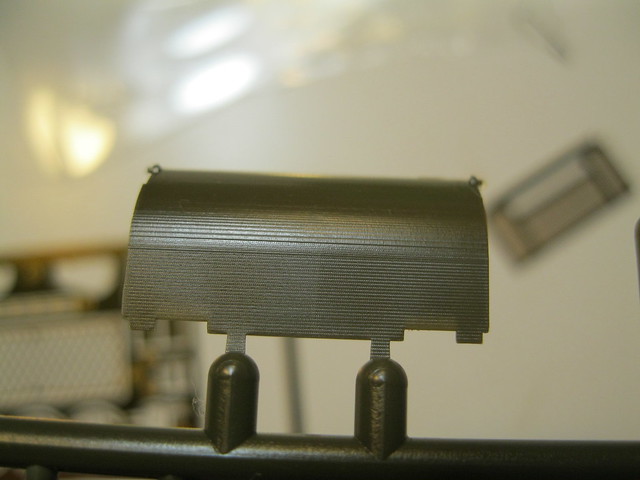

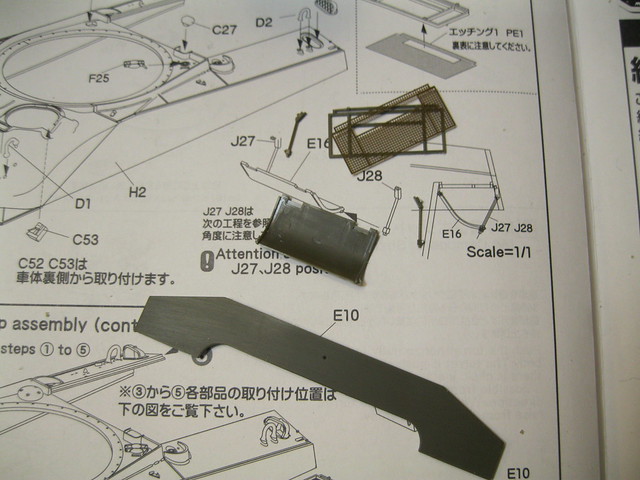

I didn't notice the lines across the rear plate until I was placing it. With the molded on details it isn't easy to clean up. I left it at this point, hoping that the added details will help cover it and no one will really be looking up the backside of the tank when it is done. Next came the placing of the small details on the rear and bottom. The engine access doors required some careful filing to get them to fit properly, something I remember from my previous Tasca kit. There are also some small sink marks visible on many of the little parts. Those on the hull bottom won't be seen. The air filters require some careful cleanup of the join seam and get small etch clamps. My CA glue was clumping and leaving little web strands so the clips look a little sloppy. I tossed that bottle and got a new one so the rest of the etch will go on cleanly.

IMG_9659

IMG_9659 by

russell amott, on Flickr

IMG_9660

IMG_9660 by

russell amott, on Flickr

IMG_9661

IMG_9661 by

russell amott, on Flickr

IMG_9662

IMG_9662 by

russell amott, on Flickr

IMG_9663

IMG_9663 by

russell amott, on Flickr

IMG_9664

IMG_9664 by

russell amott, on Flickr

IMG_9665

IMG_9665 by

russell amott, on Flickr

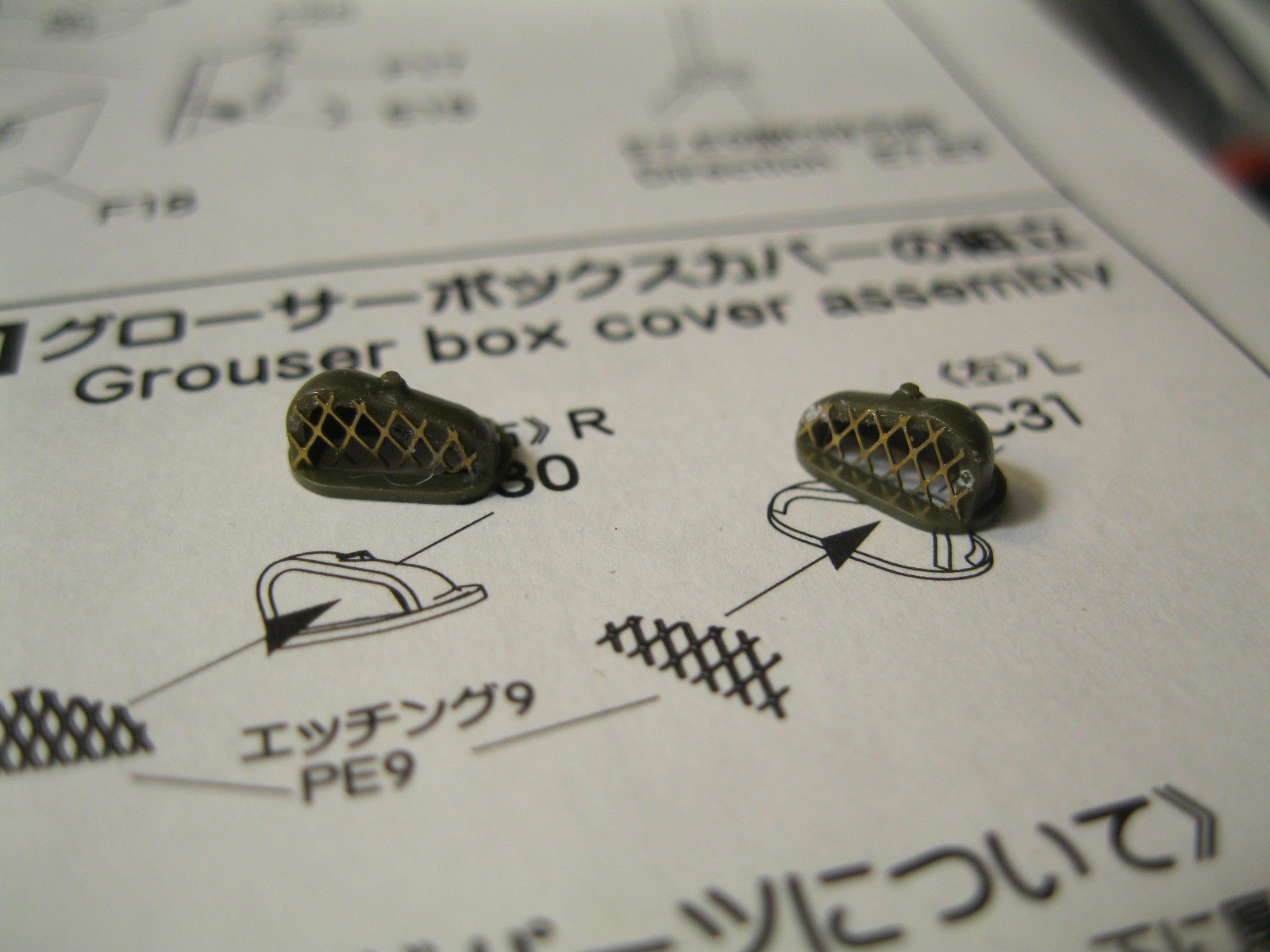

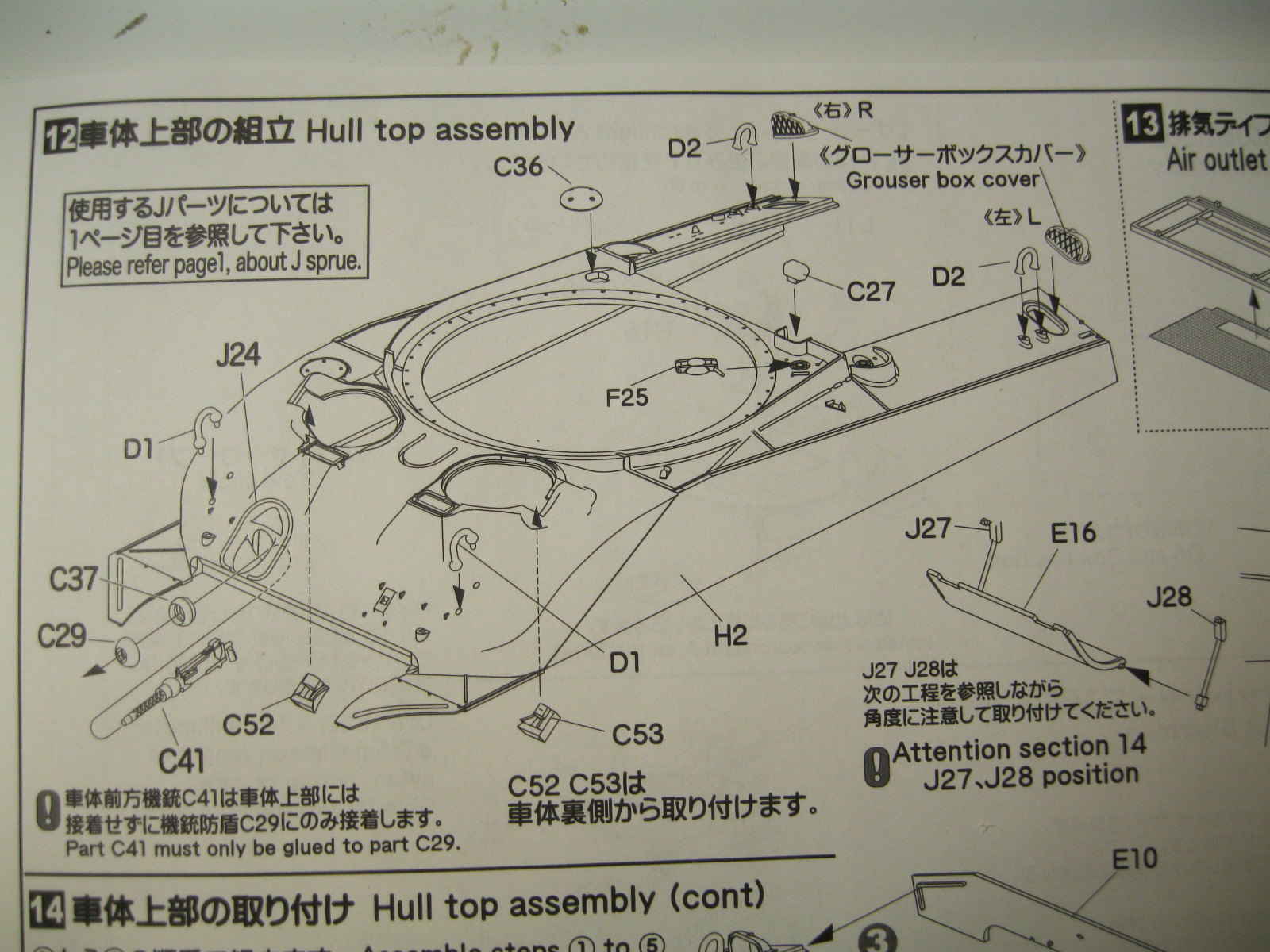

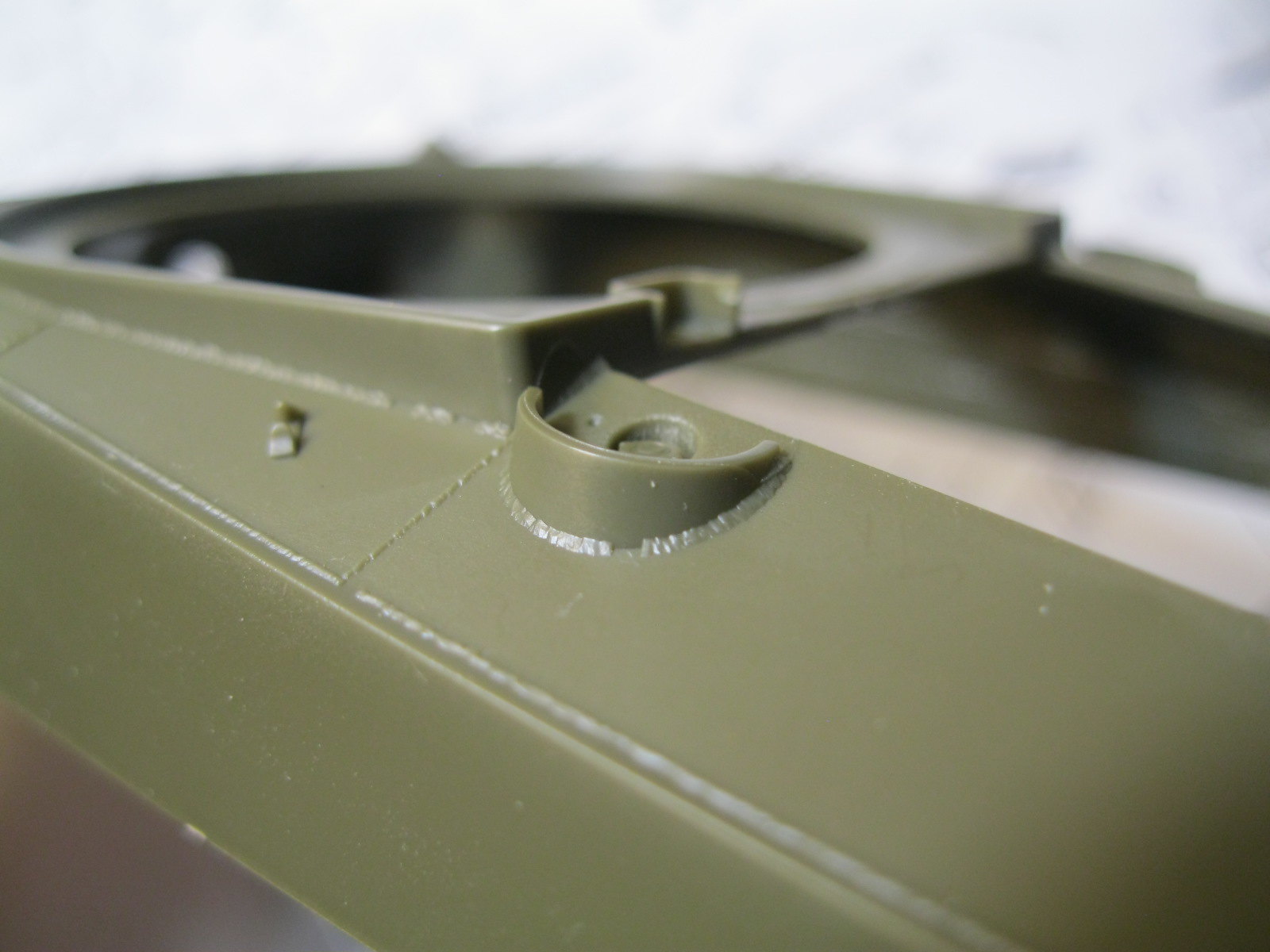

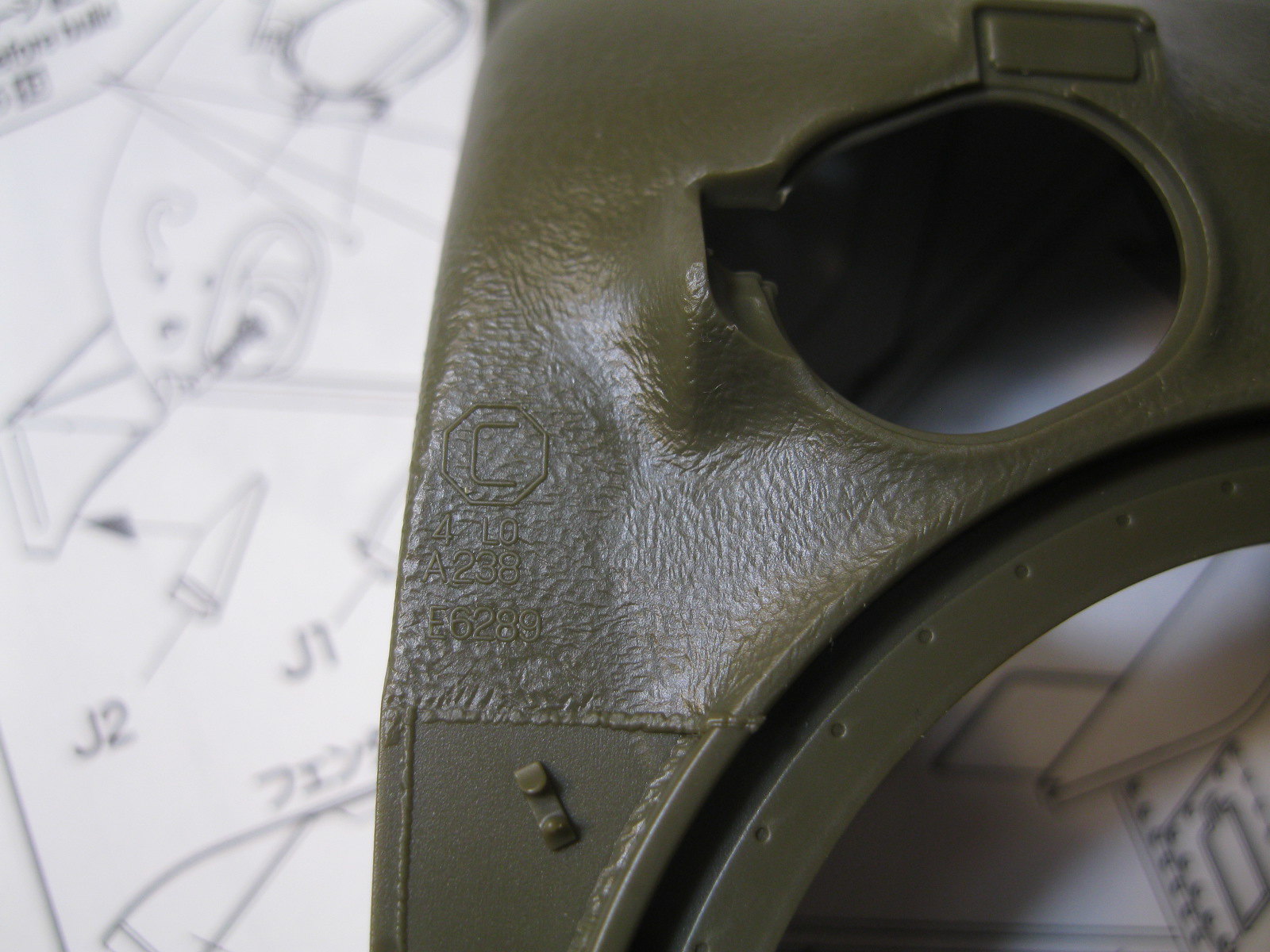

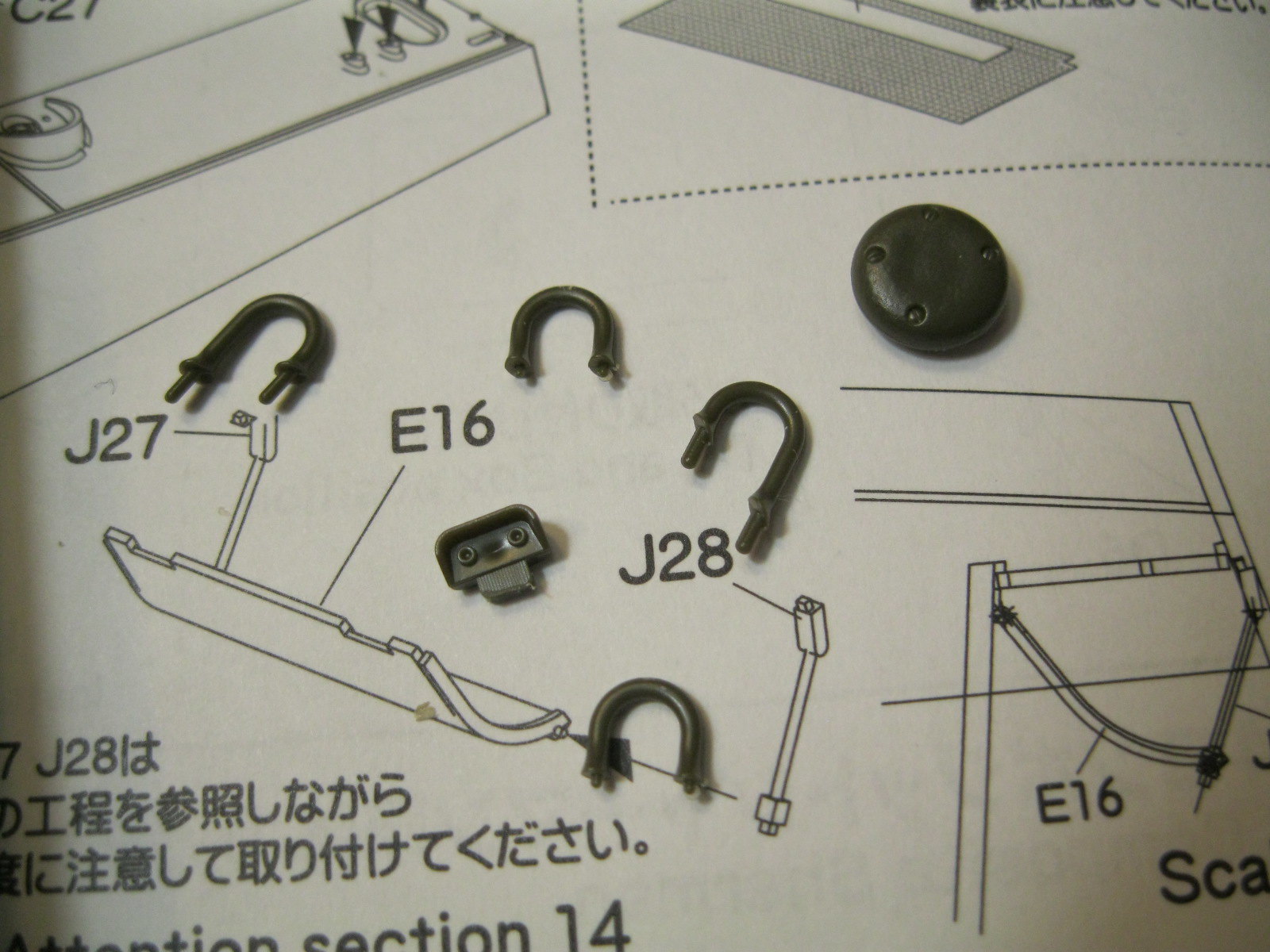

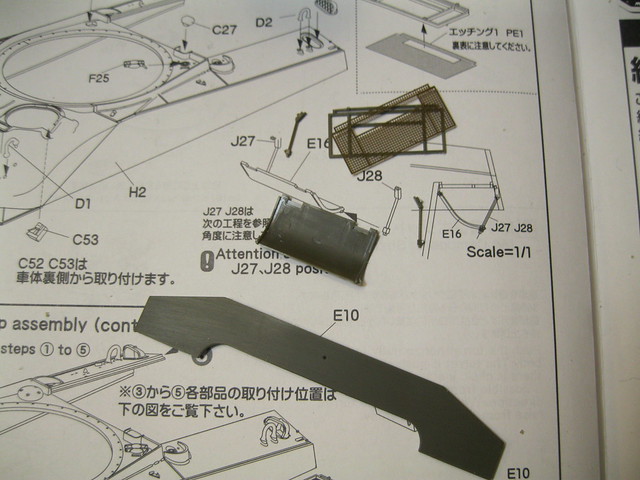

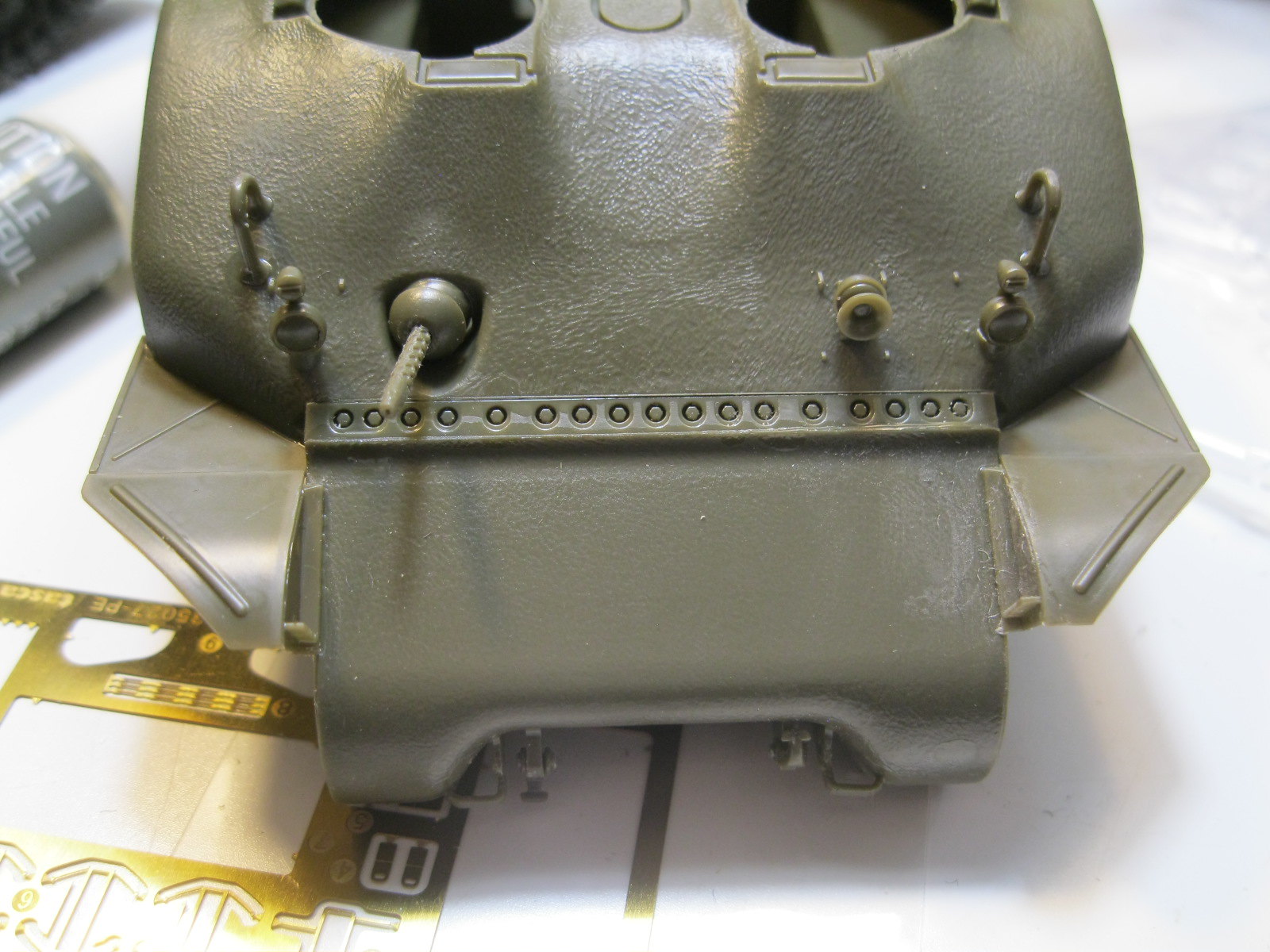

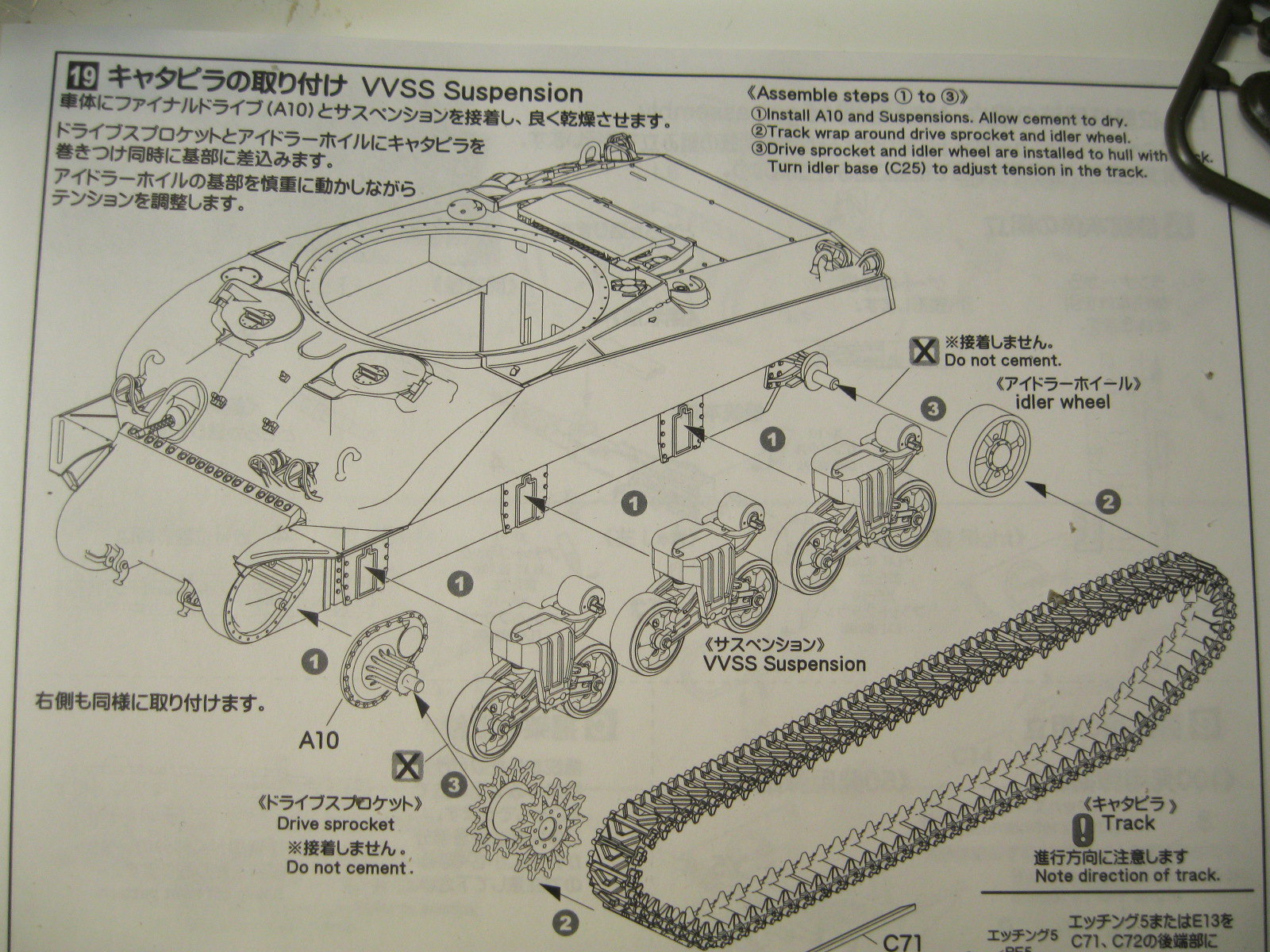

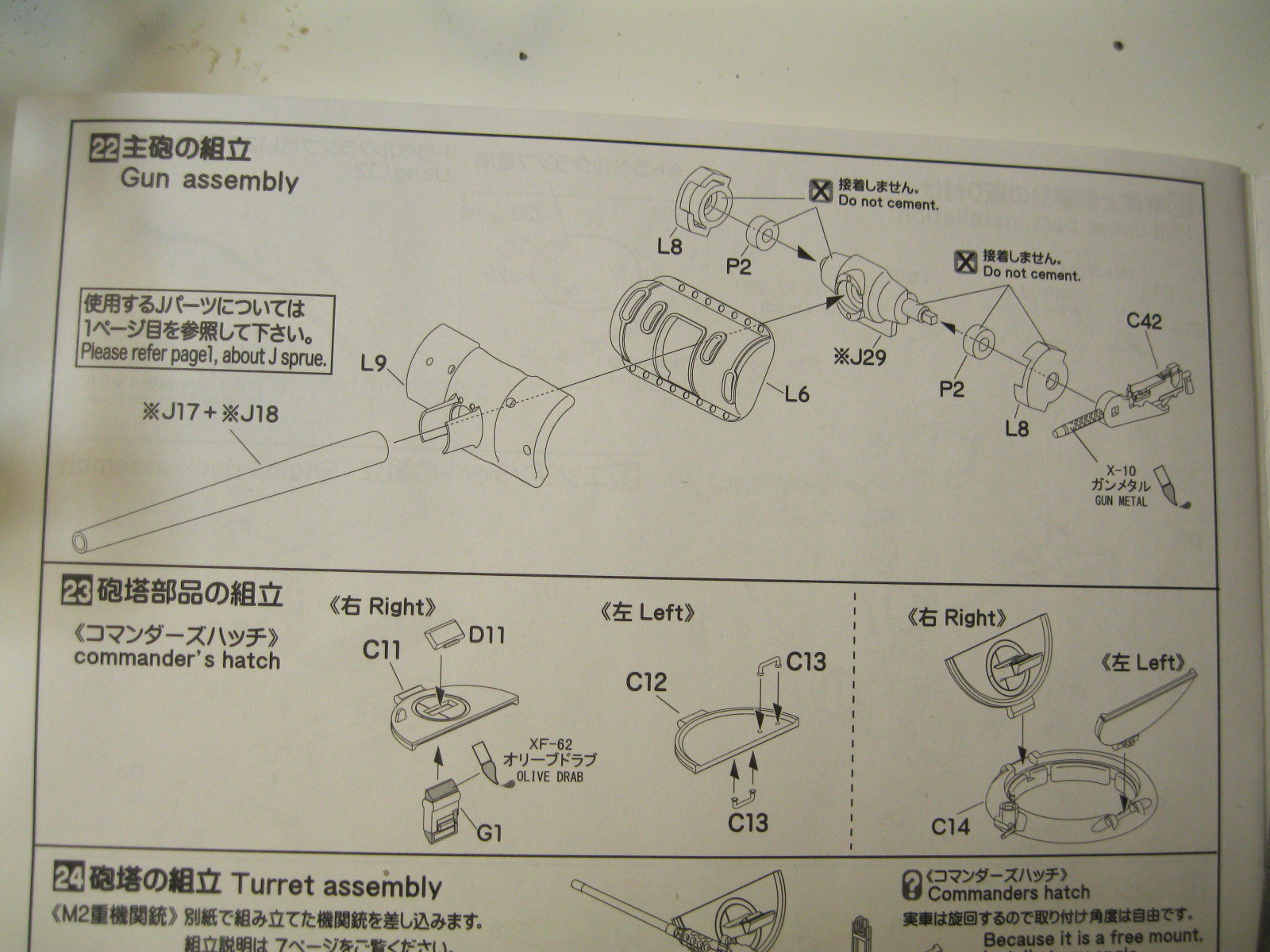

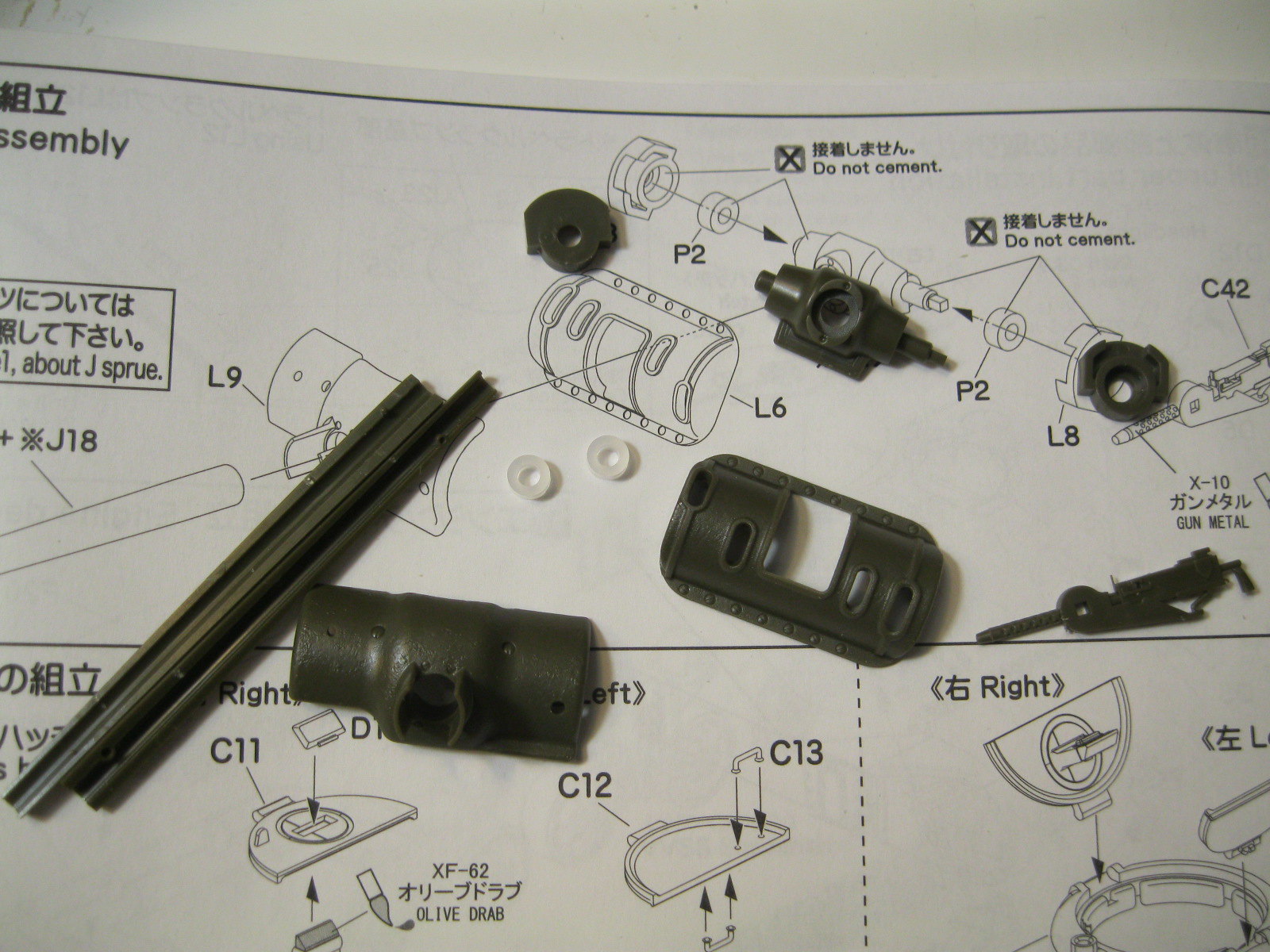

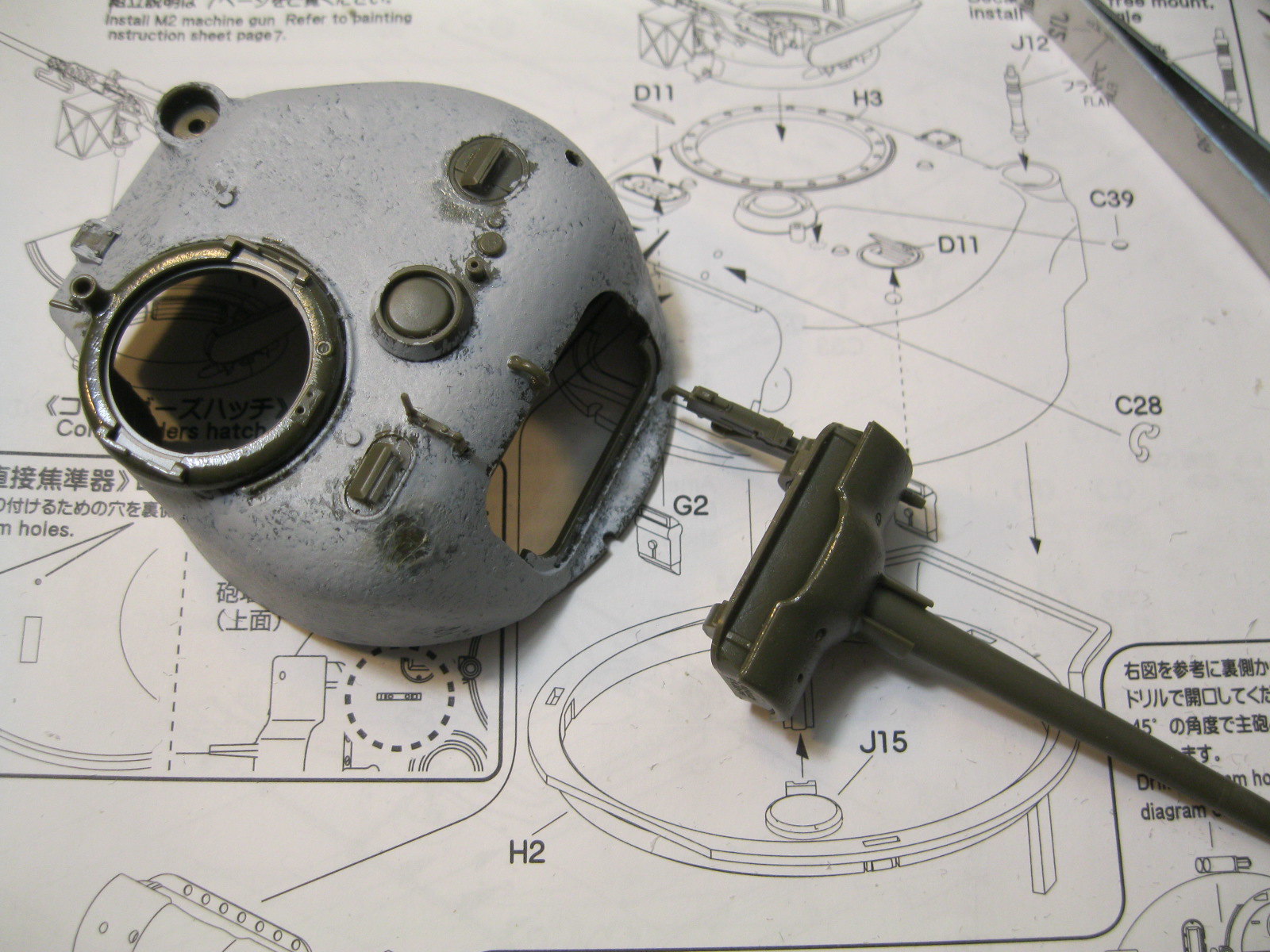

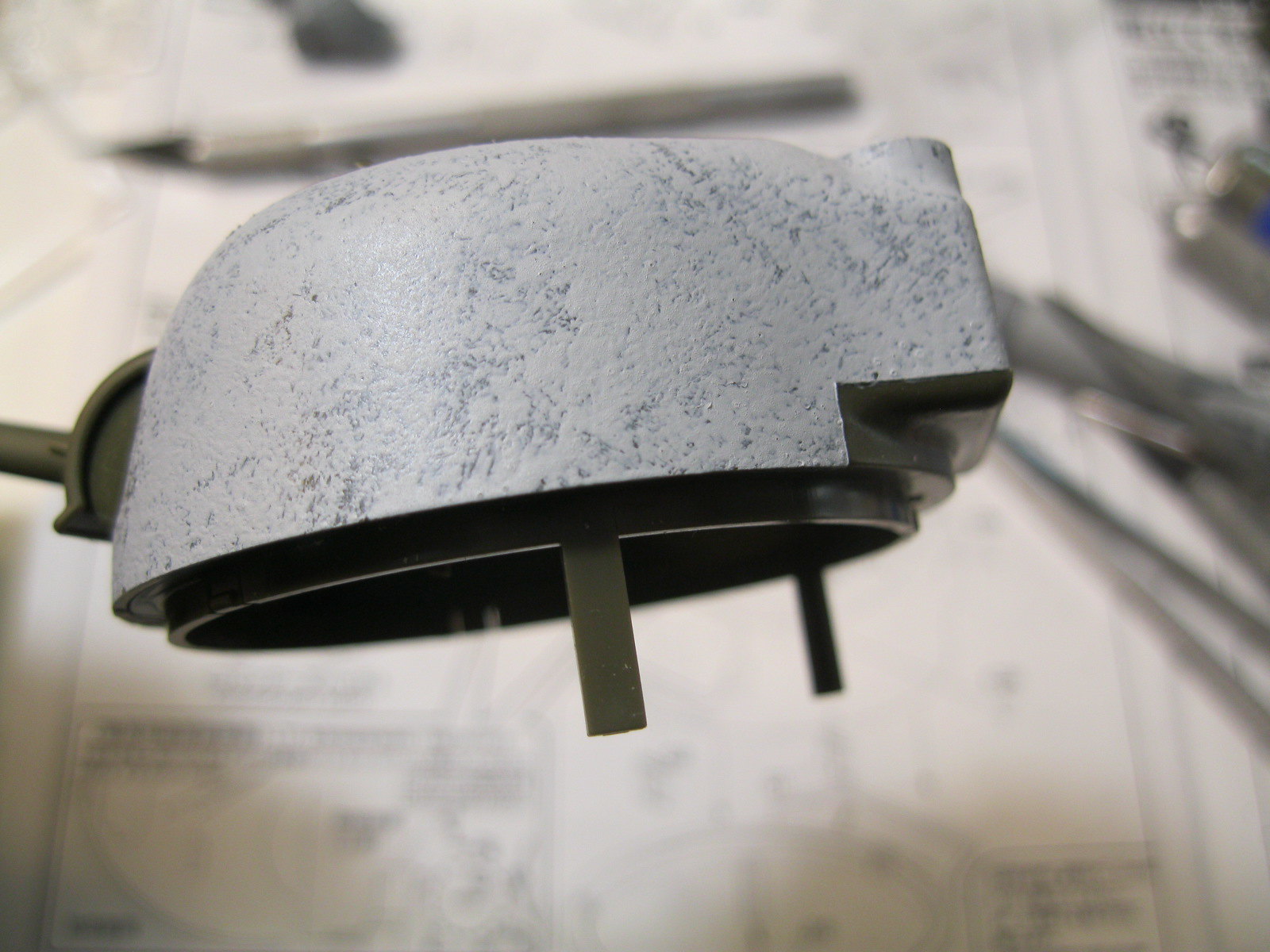

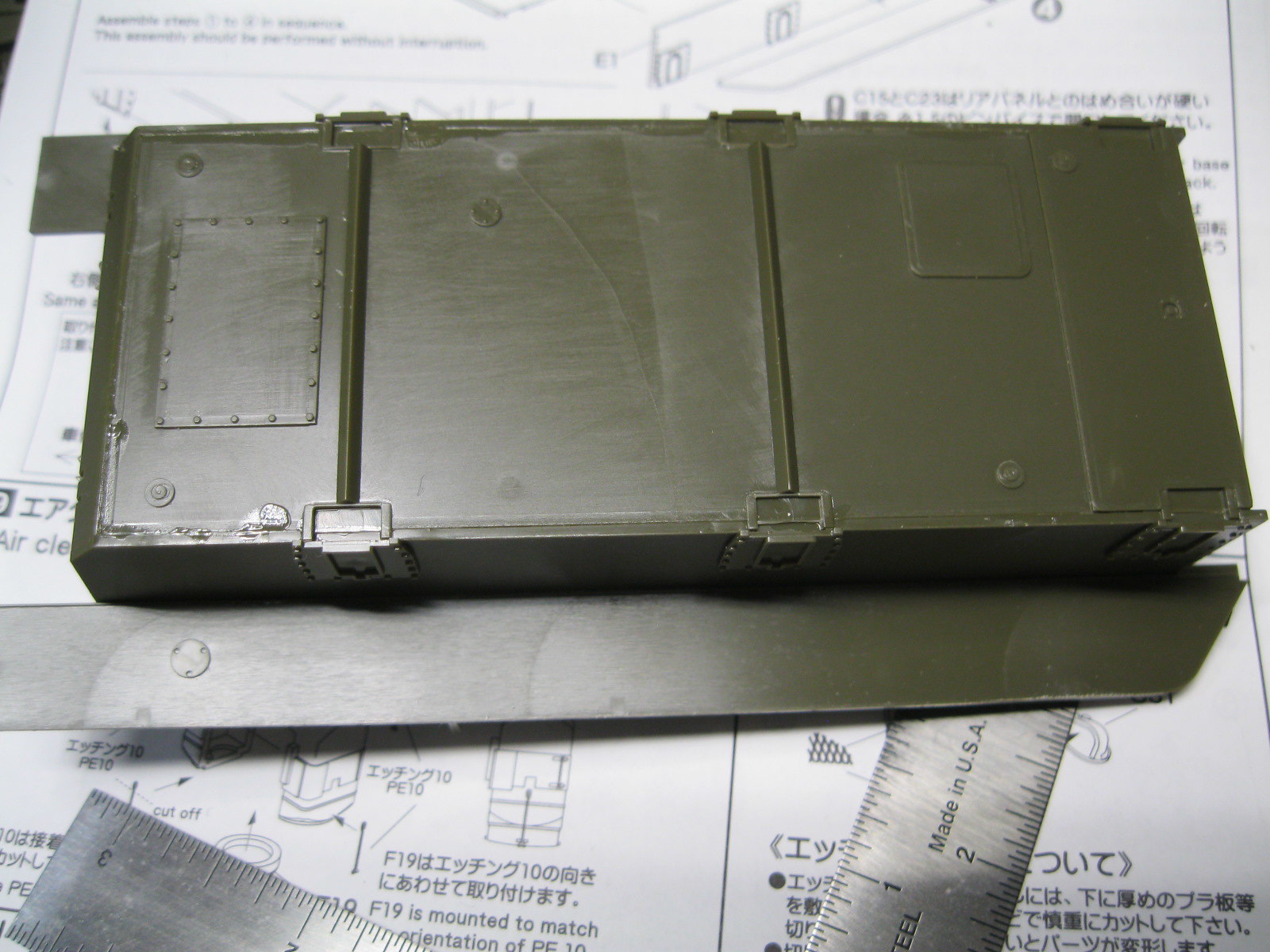

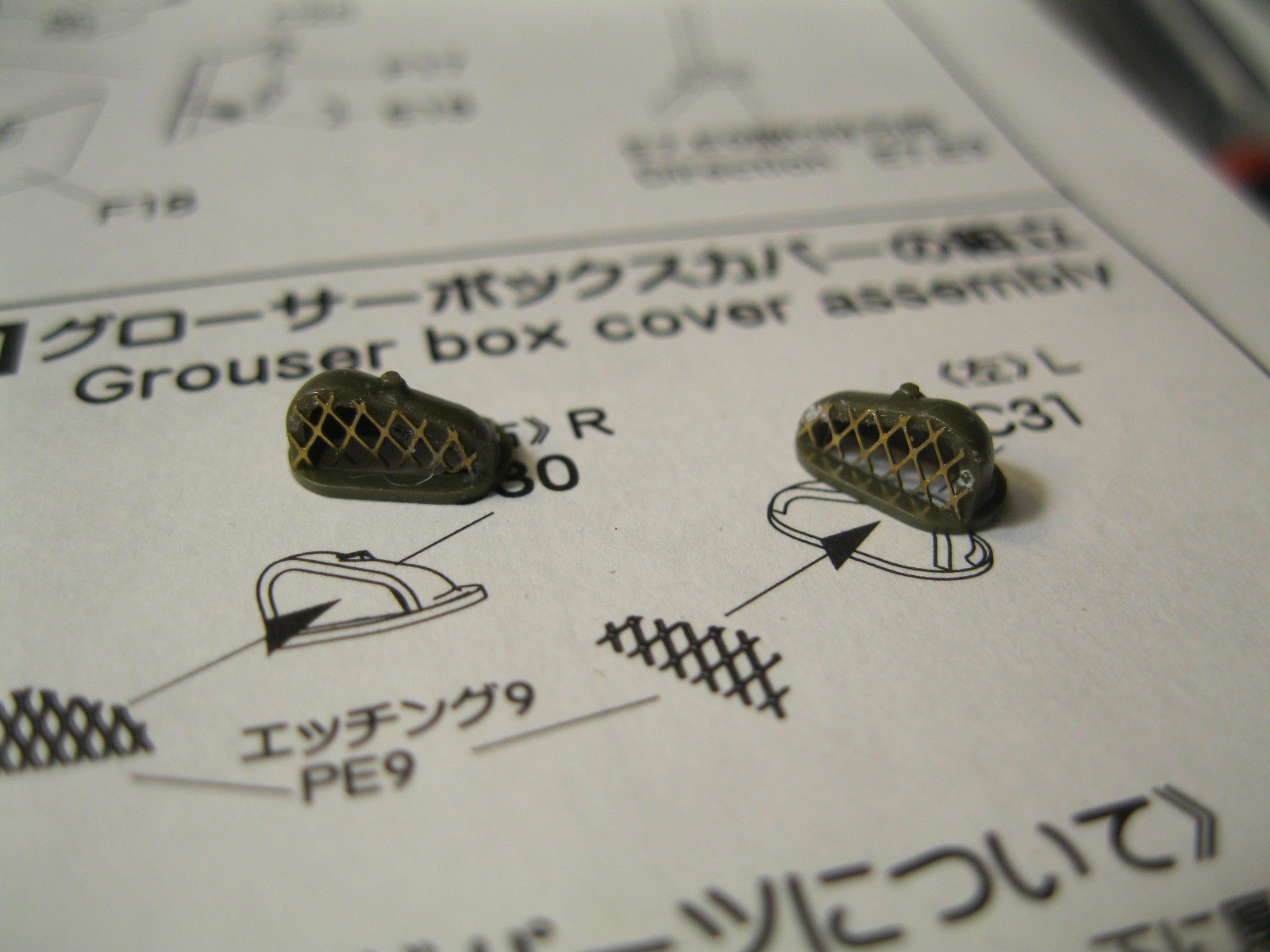

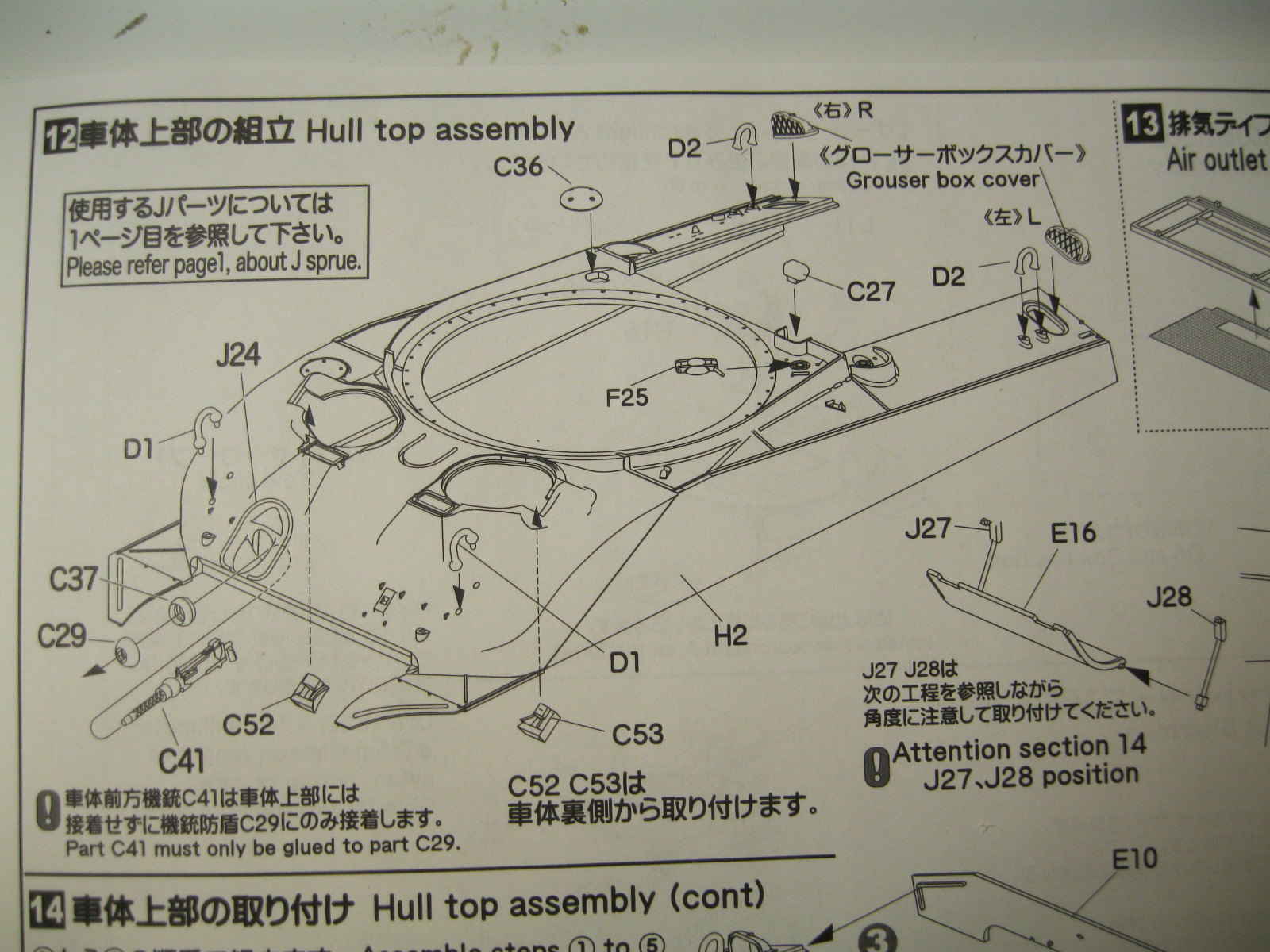

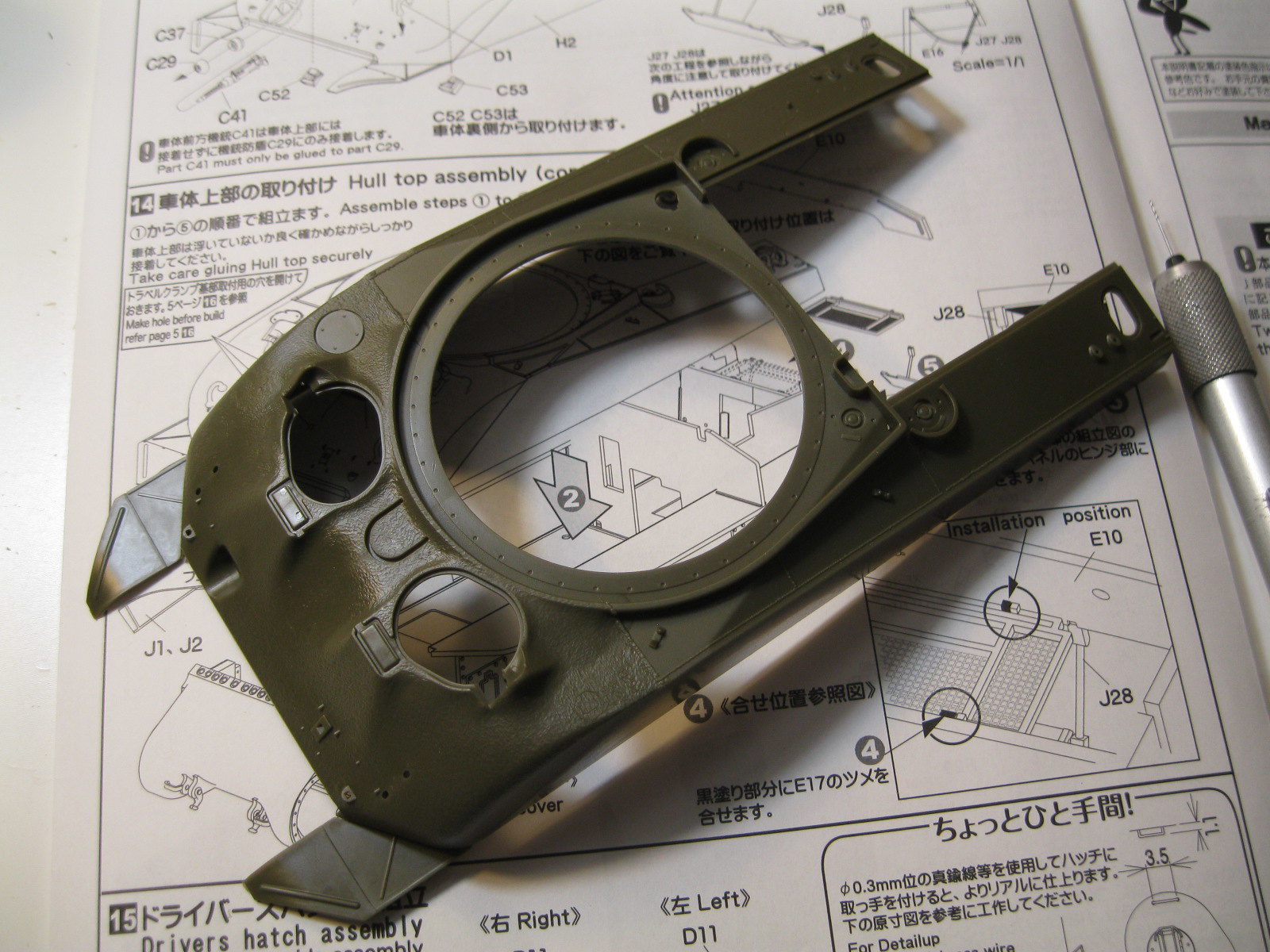

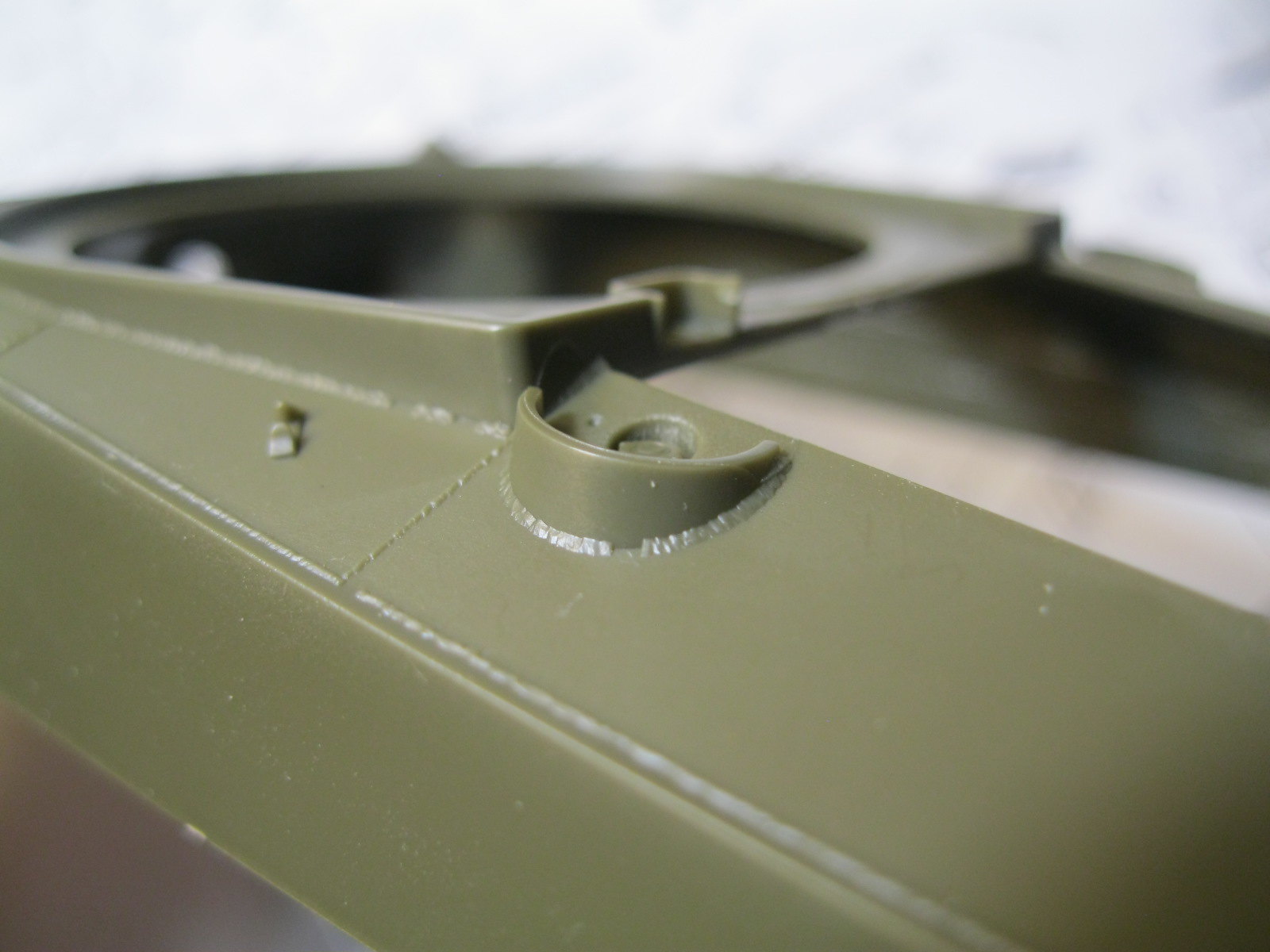

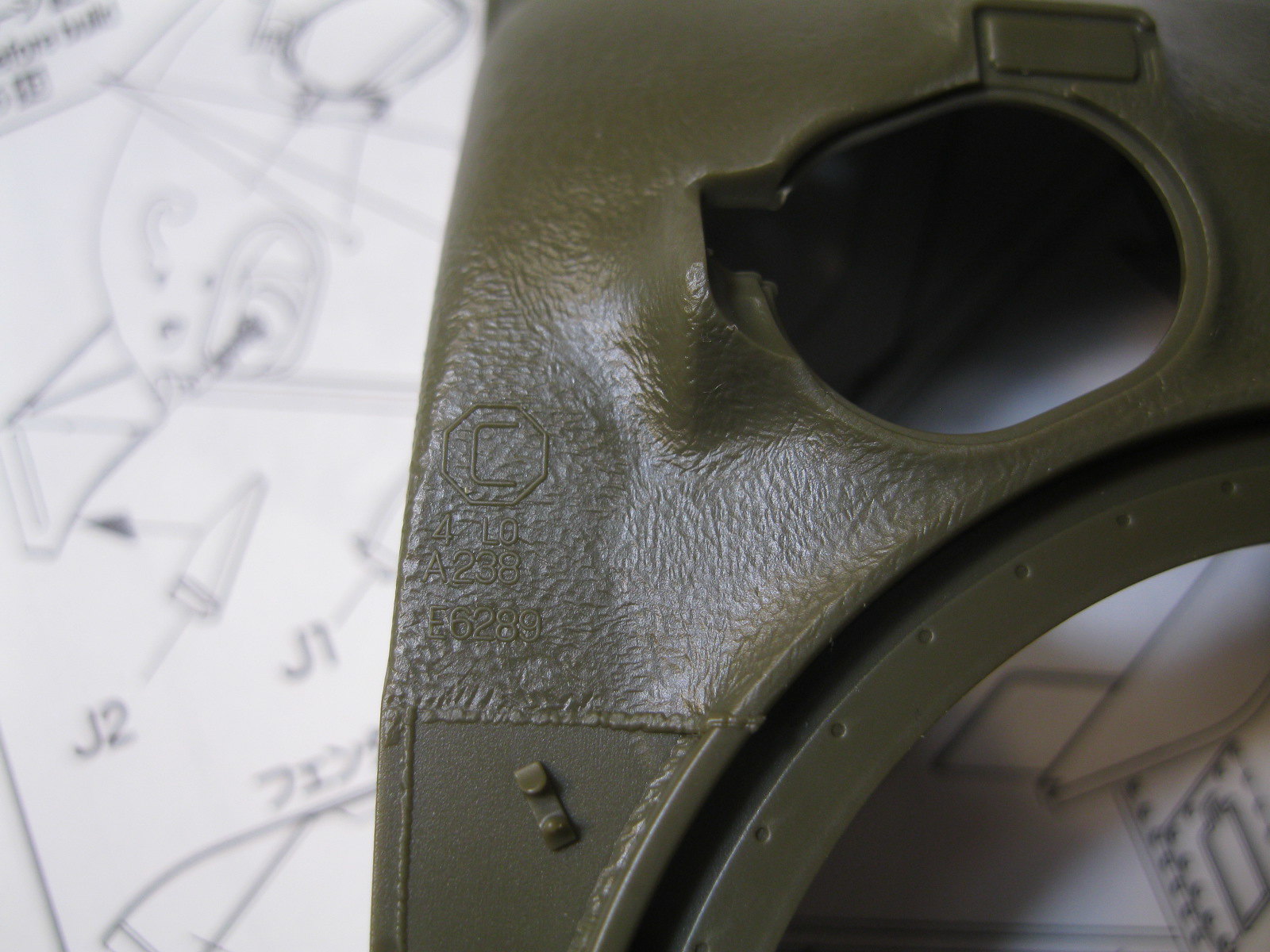

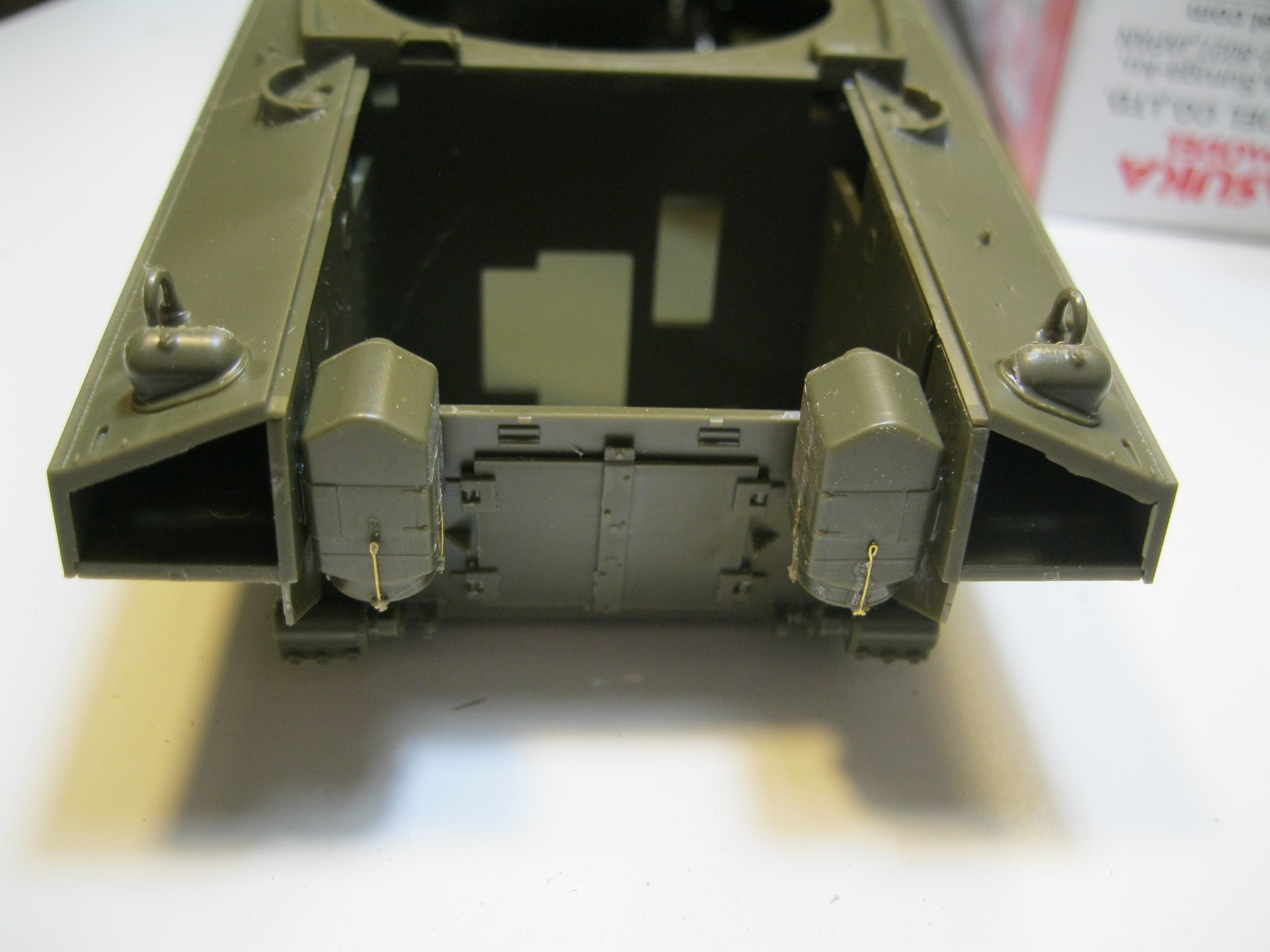

The grouser covers also get small etch screens. This is called out before the upper hull is shown but it will go right on, along with other small parts, so it is just a preparatory step. The hull is nicely done, with good casting texture on the front, a horizontal top edge where the side plates meet the engine deck and nice weld seam detail. There are small gaps in the weld bead around the turret and fuel cap splash guards for drain holes that you can add on your own. In comparing with the Dragon composite hull the only differences I can see are that the Dragon kit has softer contours around the hatches and includes the small bump on the glacis and the drain hole for the ventilator between the hatches. The foundry marks on the Tasca hull are facing opposite the Dragon marks. The Tasca kit includes a full, moveable hull MG, which I was happy to see just because it is there. German armor kits always have a highly detailed gun, even with no other interior. Allied kits usually just have a gun barrel that glues to the outside.

IMG_9666

IMG_9666 by

russell amott, on Flickr

IMG_9667

IMG_9667 by

russell amott, on Flickr

IMG_9668

IMG_9668 by

russell amott, on Flickr

IMG_9669

IMG_9669 by

russell amott, on Flickr

IMG_9670

IMG_9670 by

russell amott, on Flickr

IMG_9671

IMG_9671 by

russell amott, on Flickr

IMG_9672

IMG_9672 by

russell amott, on Flickr

IMG_9673

IMG_9673 by

russell amott, on Flickr

IMG_9674

IMG_9674 by

russell amott, on Flickr

IMG_9675

IMG_9675 by

russell amott, on Flickr

IMG_9677

IMG_9677 by

russell amott, on Flickr

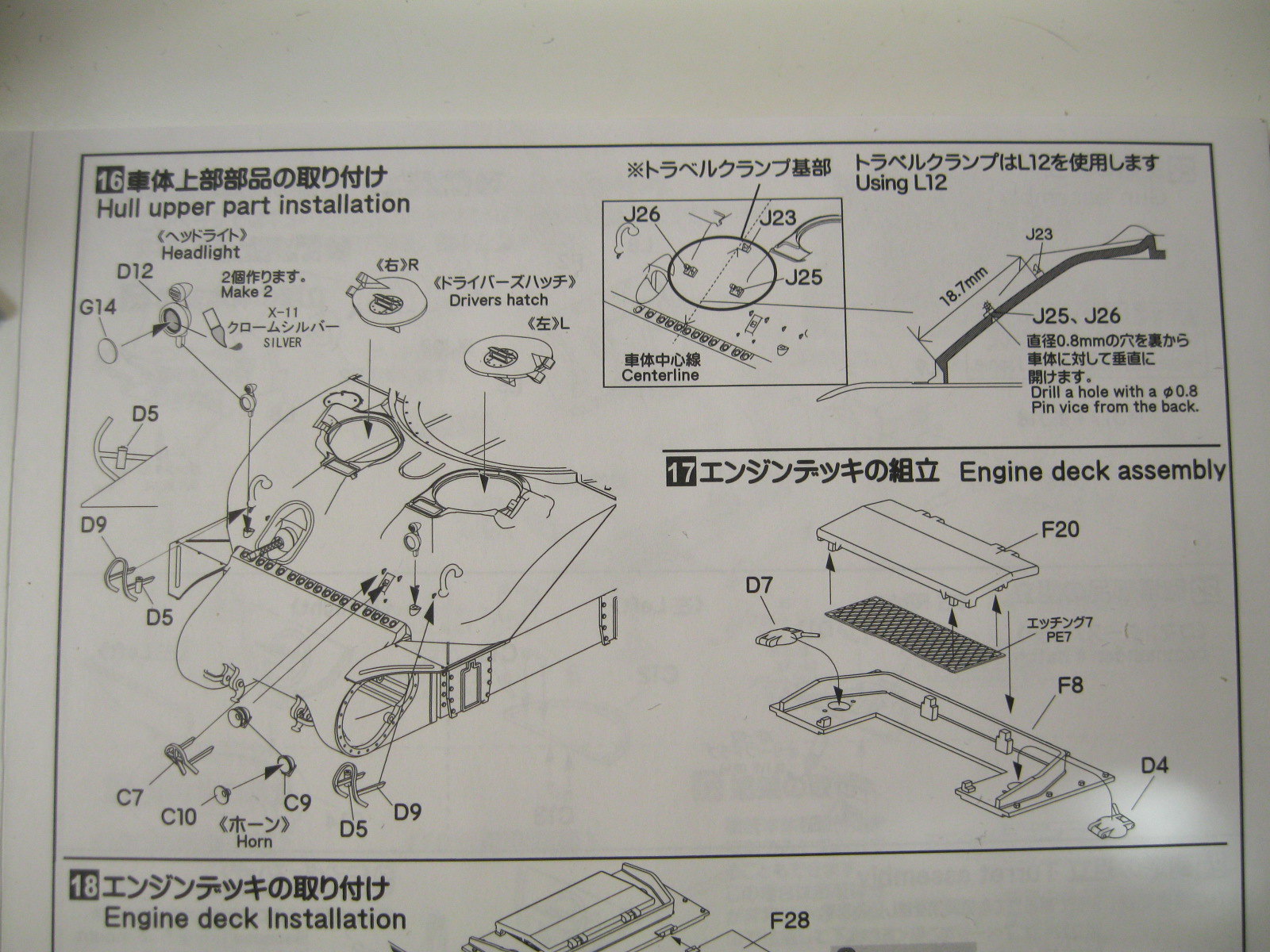

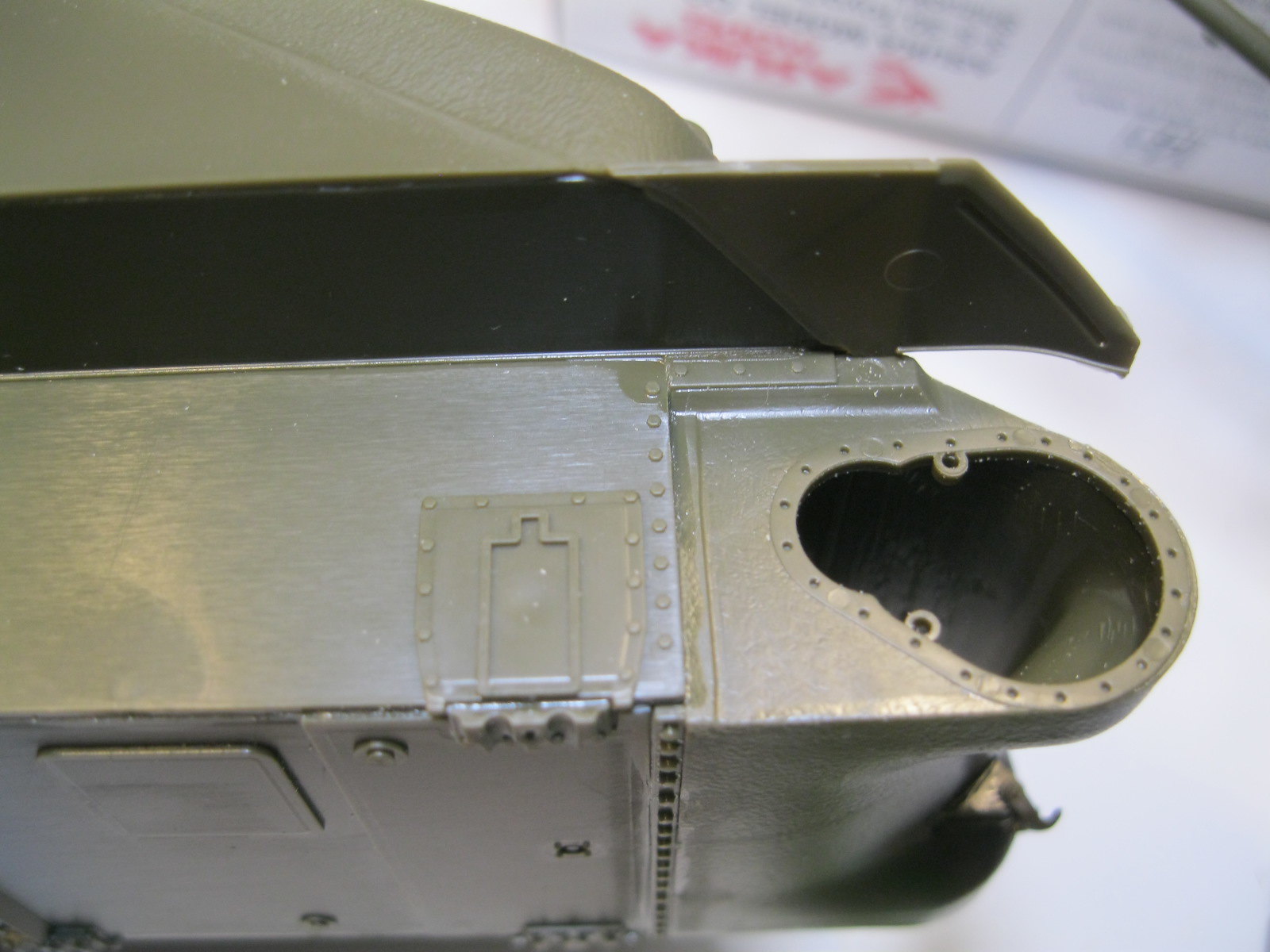

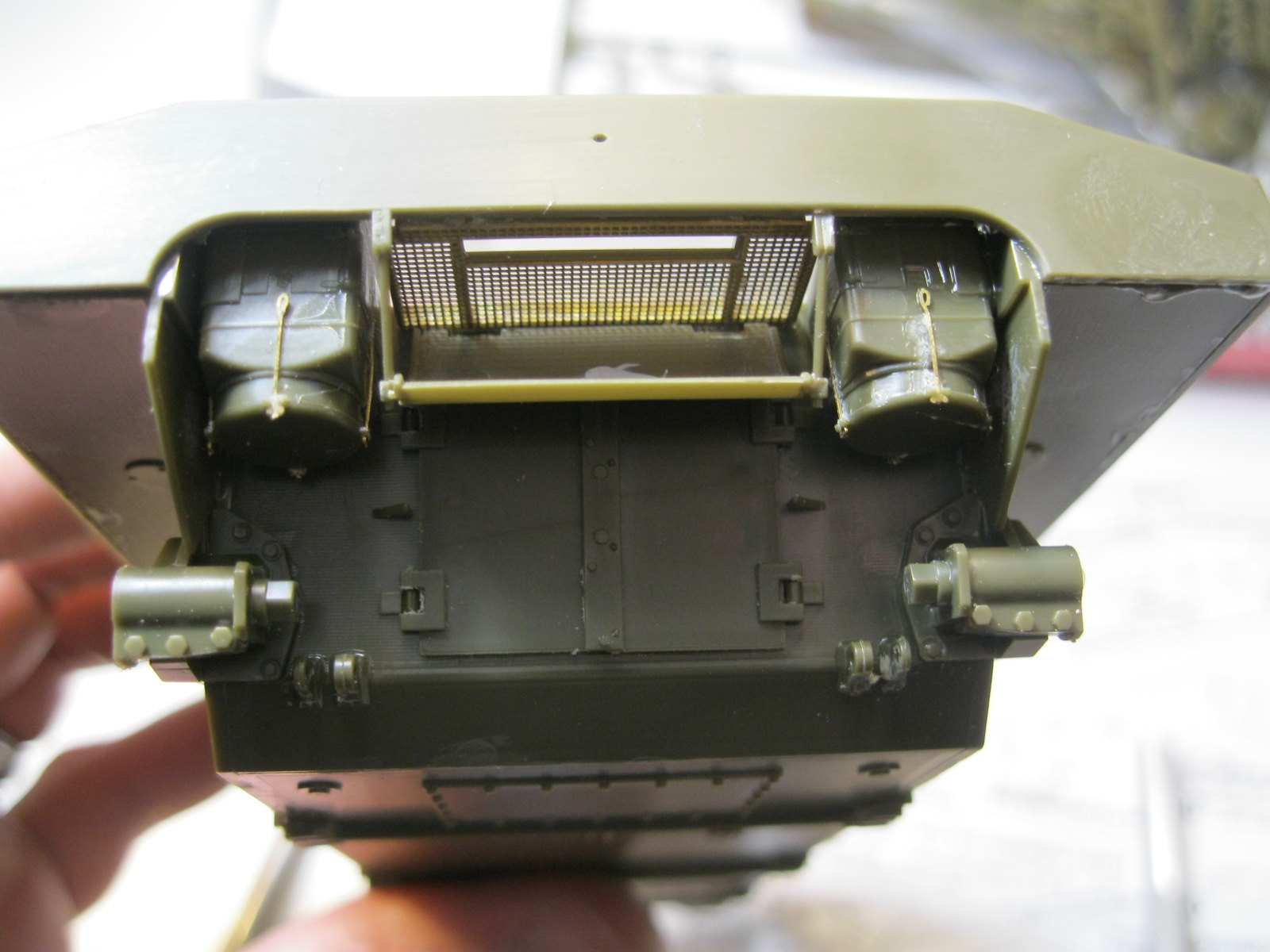

At this point the upper and lower hull sections can be joined. For me it was easier to start with the differential housing and then place the upper hull. Test fitting showed a couple of areas that needed some careful filing to get a nice fit, and then everything was glued, working around the edges slowly. Of note, the instructions say to drill three holes in the glacis to place the brackets for the barrel lock. The travel lock isn't present in the photo of China Clipper, but the locking clip is and I suspect the foot mounts are under the stowage.

IMG_9680

IMG_9680 by

russell amott, on Flickr

IMG_9681

IMG_9681 by

russell amott, on Flickr

IMG_9682

IMG_9682 by

russell amott, on Flickr

IMG_9683

IMG_9683 by

russell amott, on Flickr

IMG_9684

IMG_9684 by

russell amott, on Flickr

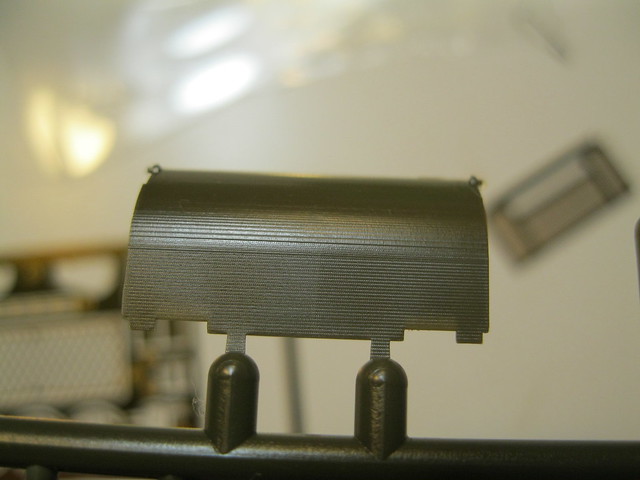

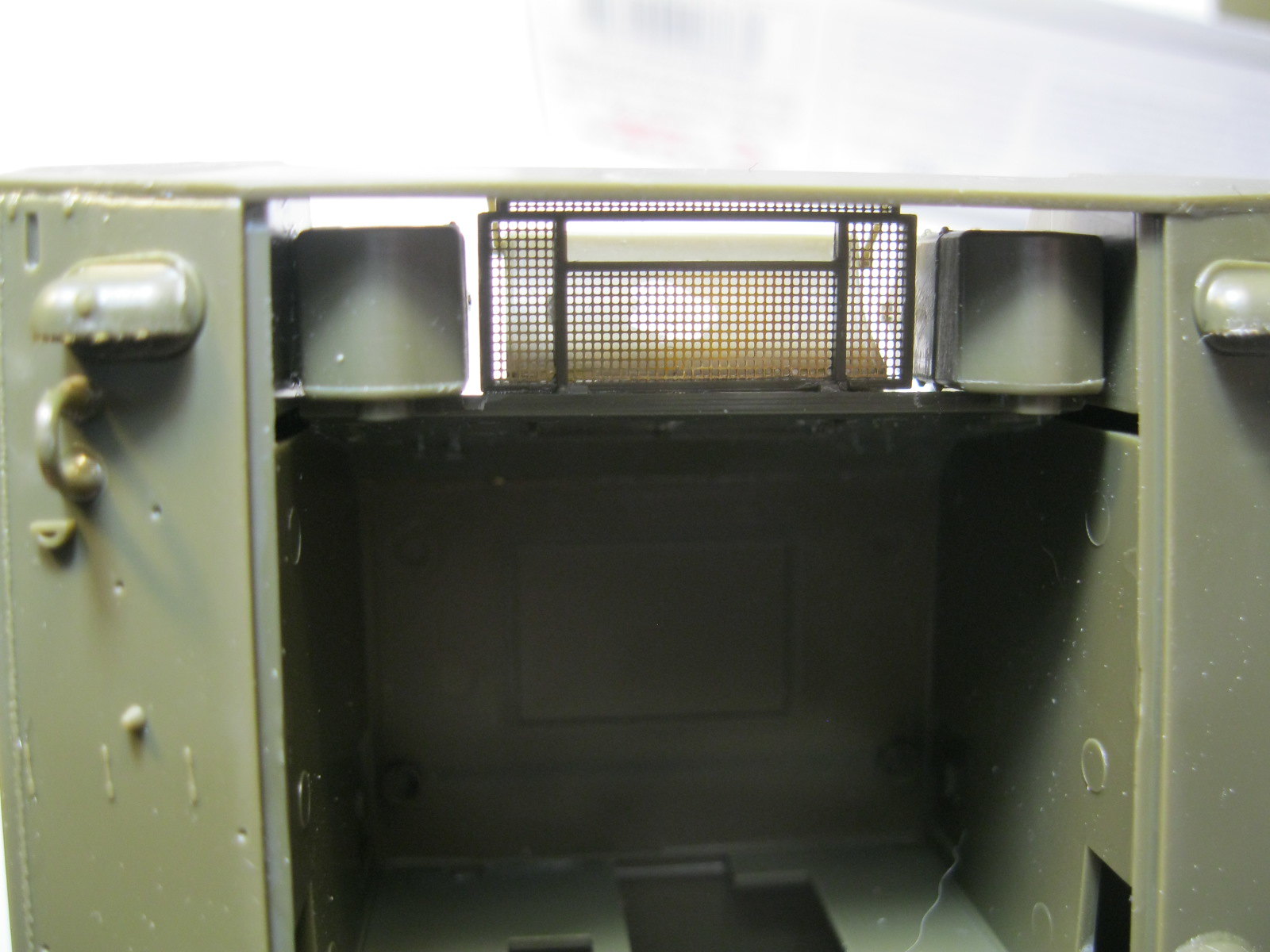

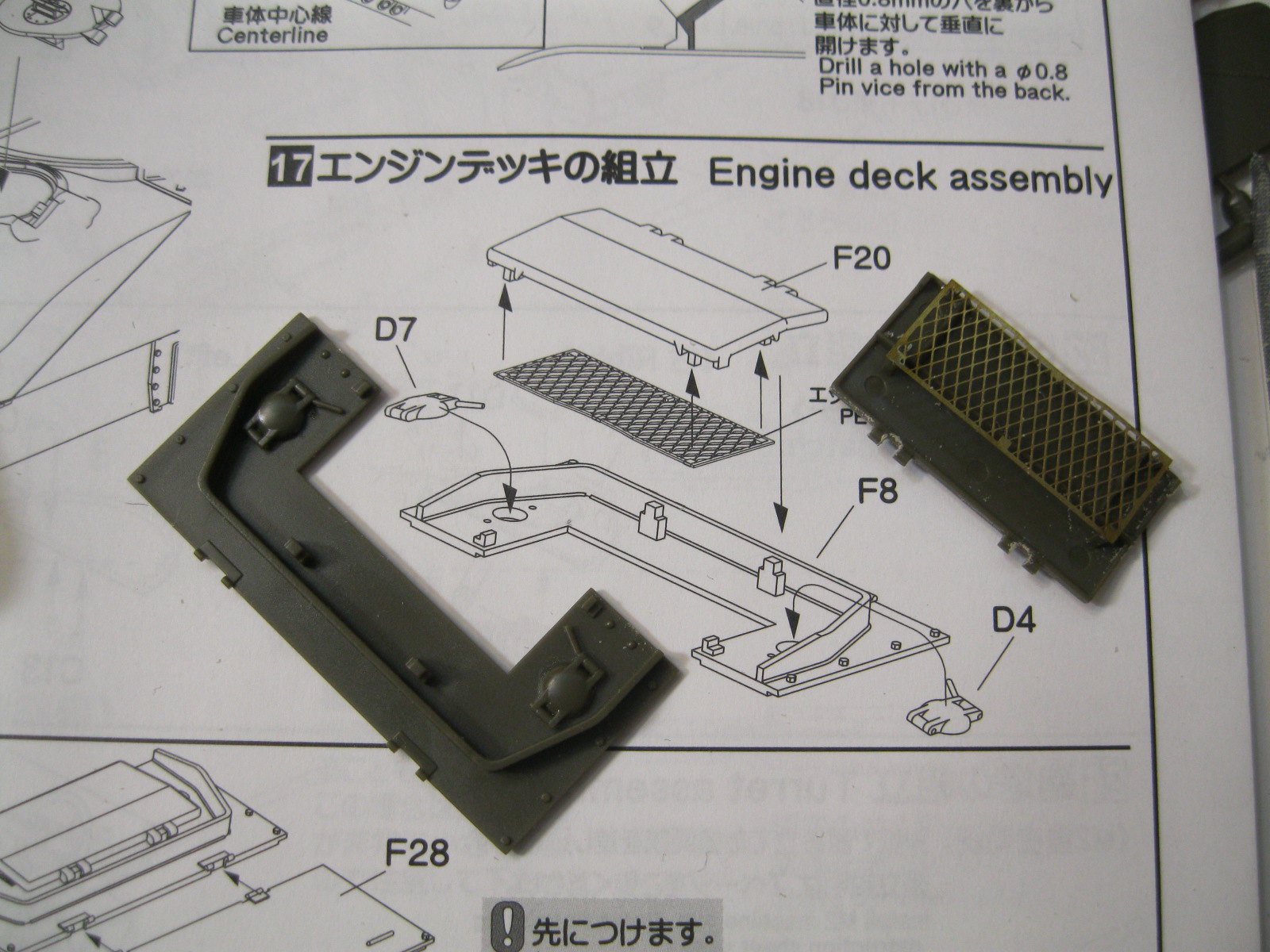

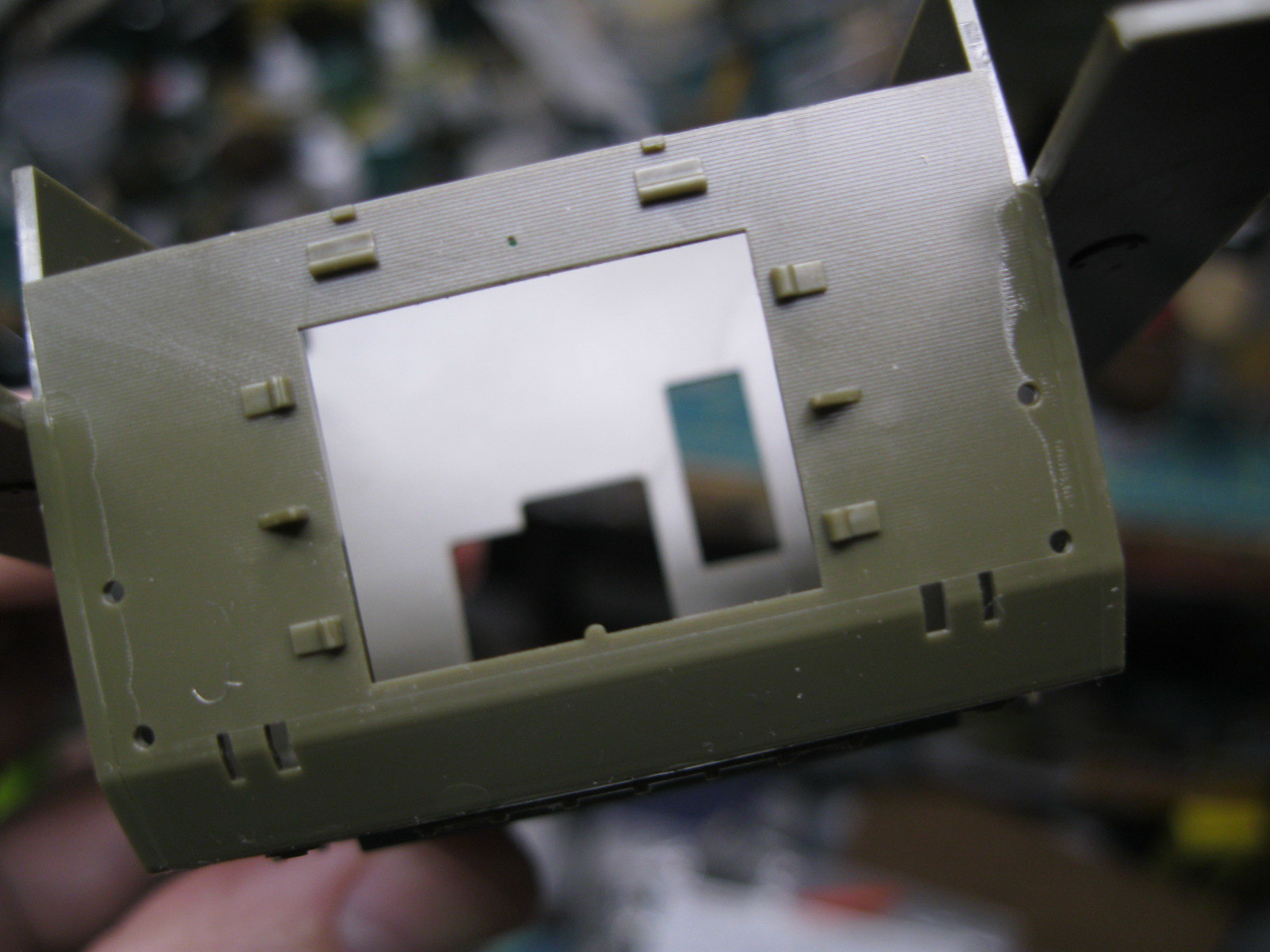

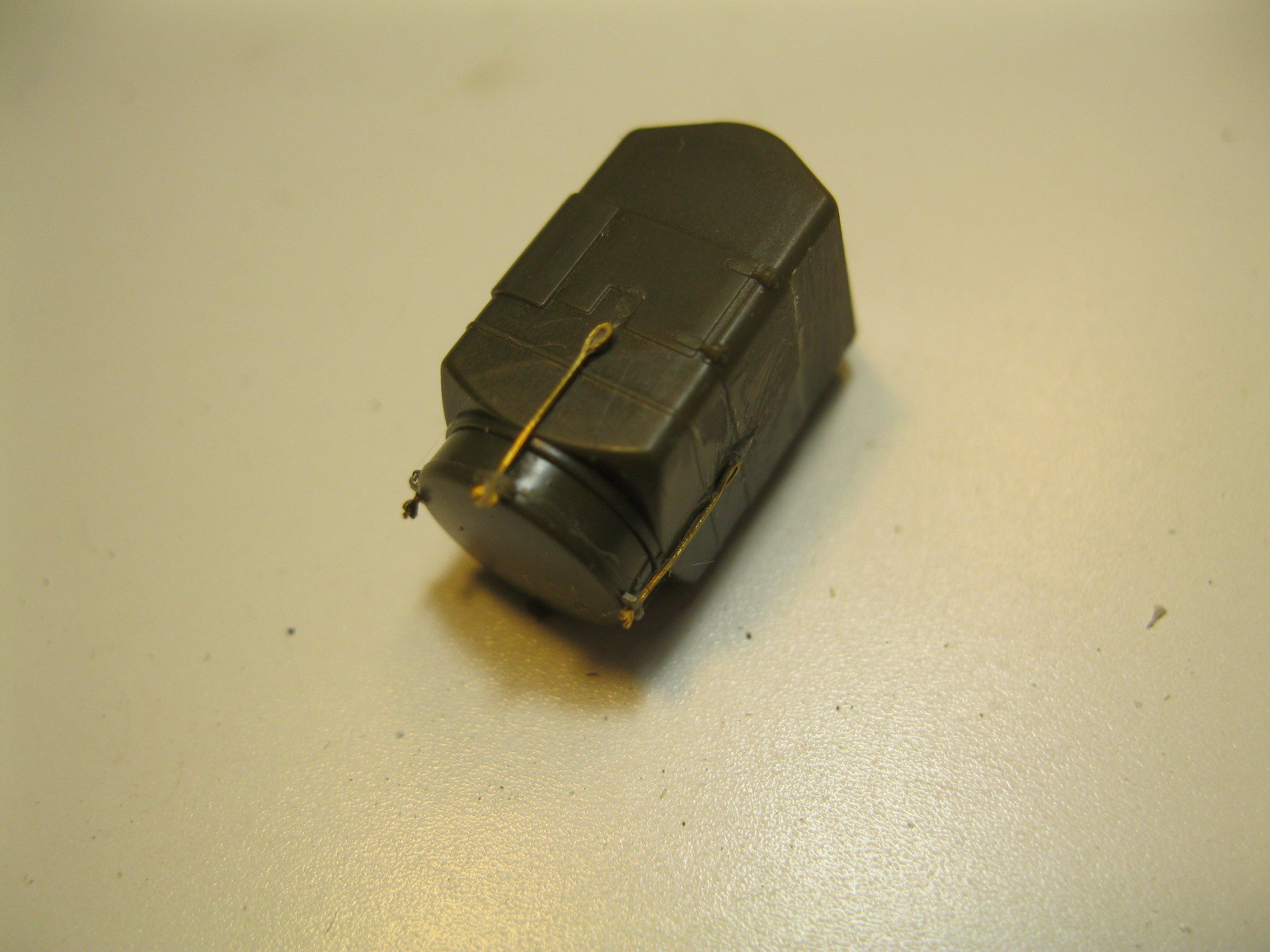

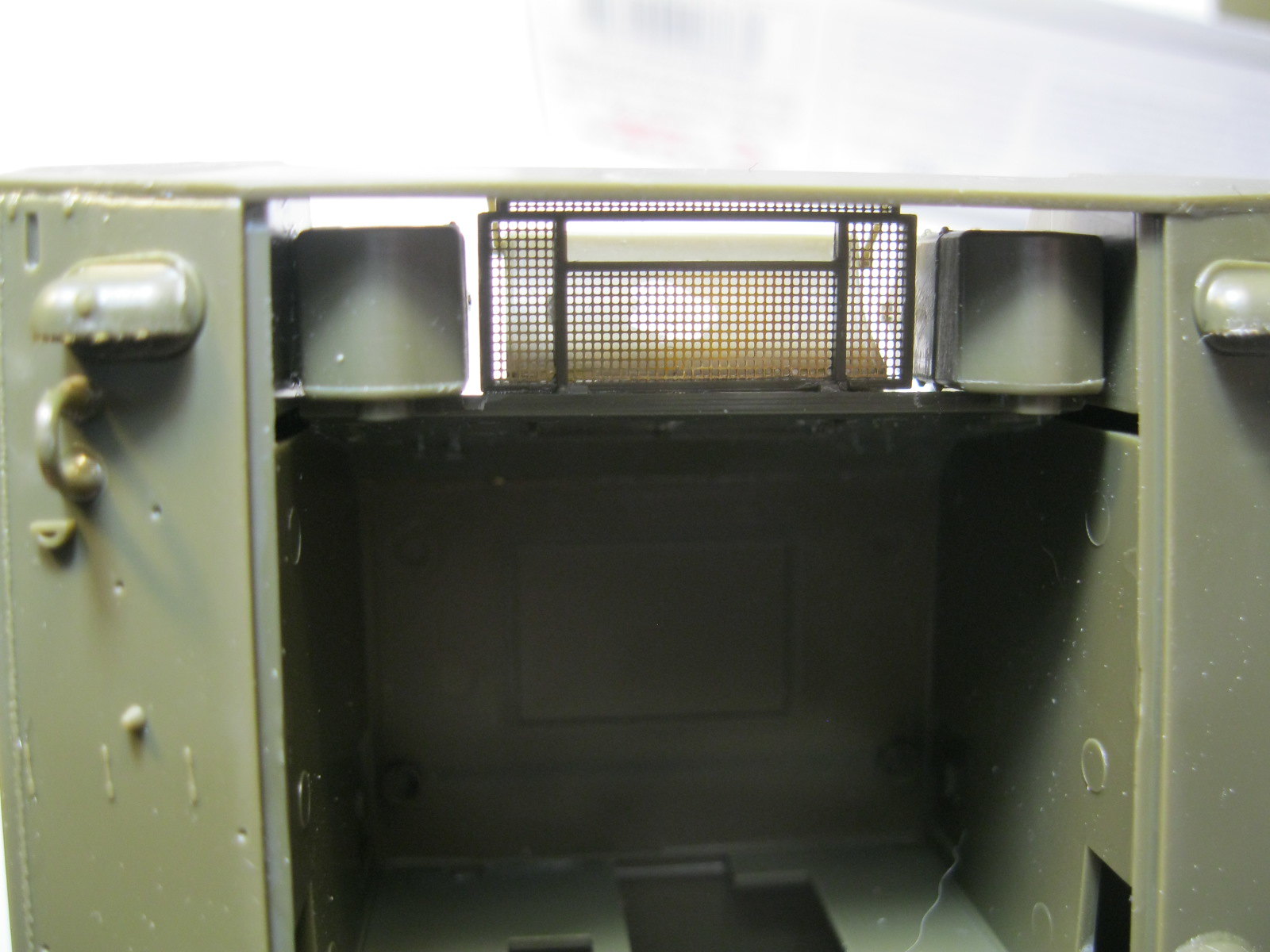

Next up is the exhaust deflector and rear plate. These parts also have the finely lined surface. I pulled out some steel wool and went over the parts carefully. The deflector is textured this way on the back surface. The front has three ejector pin marks that I worked to smooth out. The middle one received a dab of filler and was then smoothed. The etch screen rests on a plastic frame that has tiny attachment points. I placed the rear plate and then added these small details.

IMG_9678

IMG_9678 by

russell amott, on Flickr

IMG_9679

IMG_9679 by

russell amott, on Flickr

IMG_9685

IMG_9685 by

russell amott, on Flickr

IMG_9690

IMG_9690 by

russell amott, on Flickr

IMG_9691

IMG_9691 by

russell amott, on Flickr

I was just about to start on the hull hatches but was given a gentle reminder to take a break and play with someone.

IMG_9692

IMG_9692 by

russell amott, on Flickr

IMG_9695

IMG_9695 by

russell amott, on Flickr

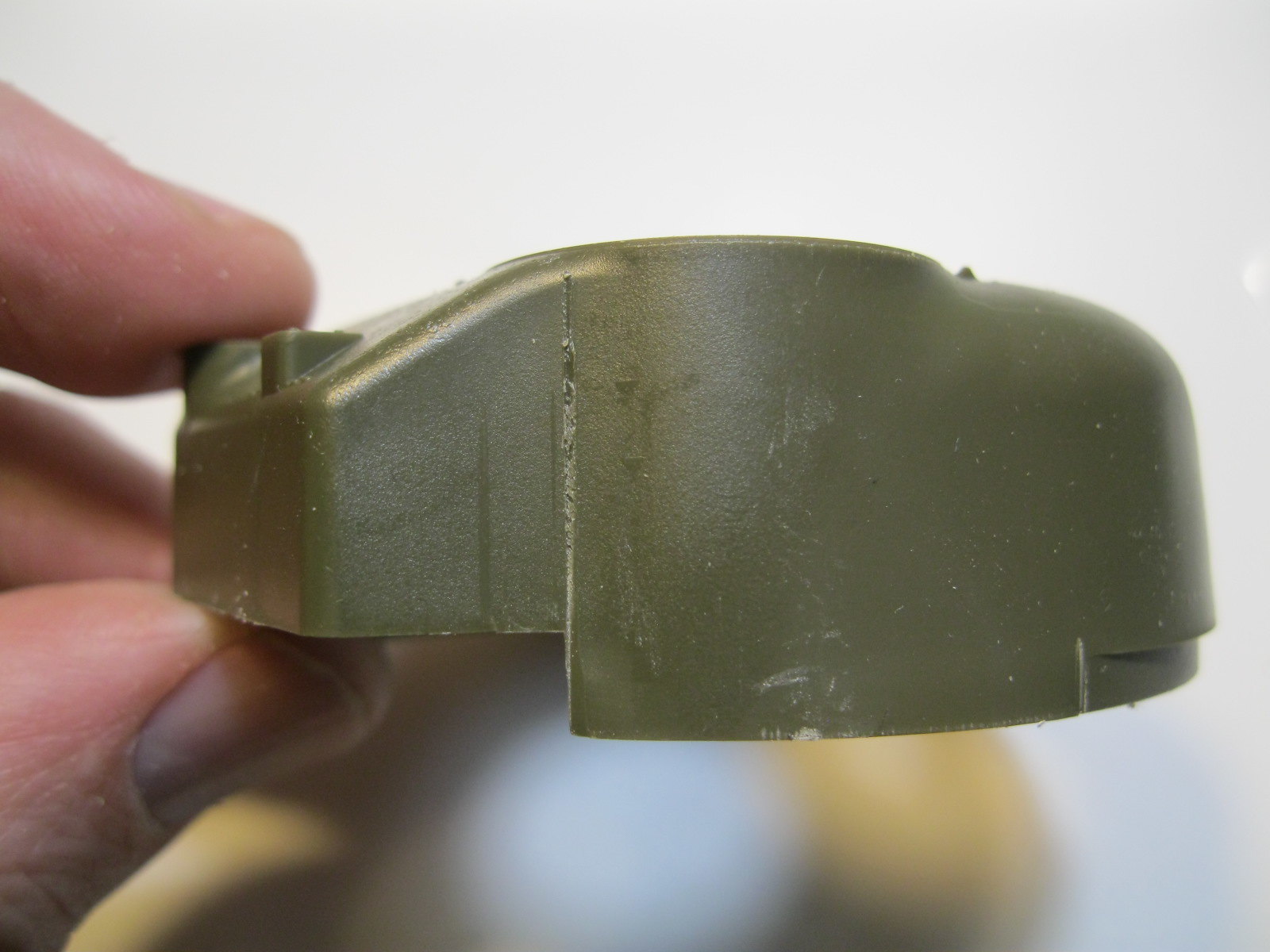

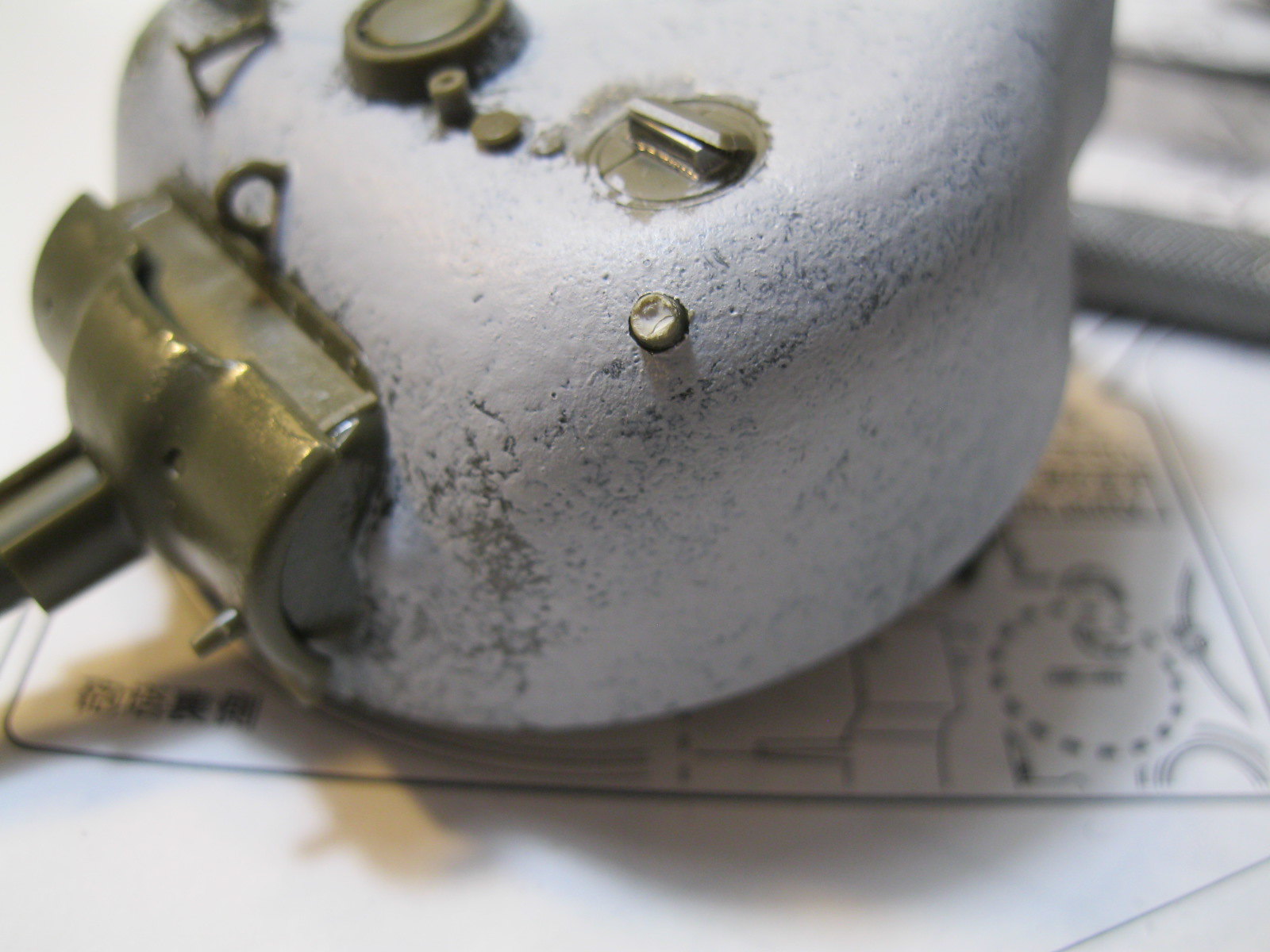

That is all for now. After playtime I will get back to the hatches. I also did some texturing on the turret to give it time to set. Still lots of things to do but life has priorities.

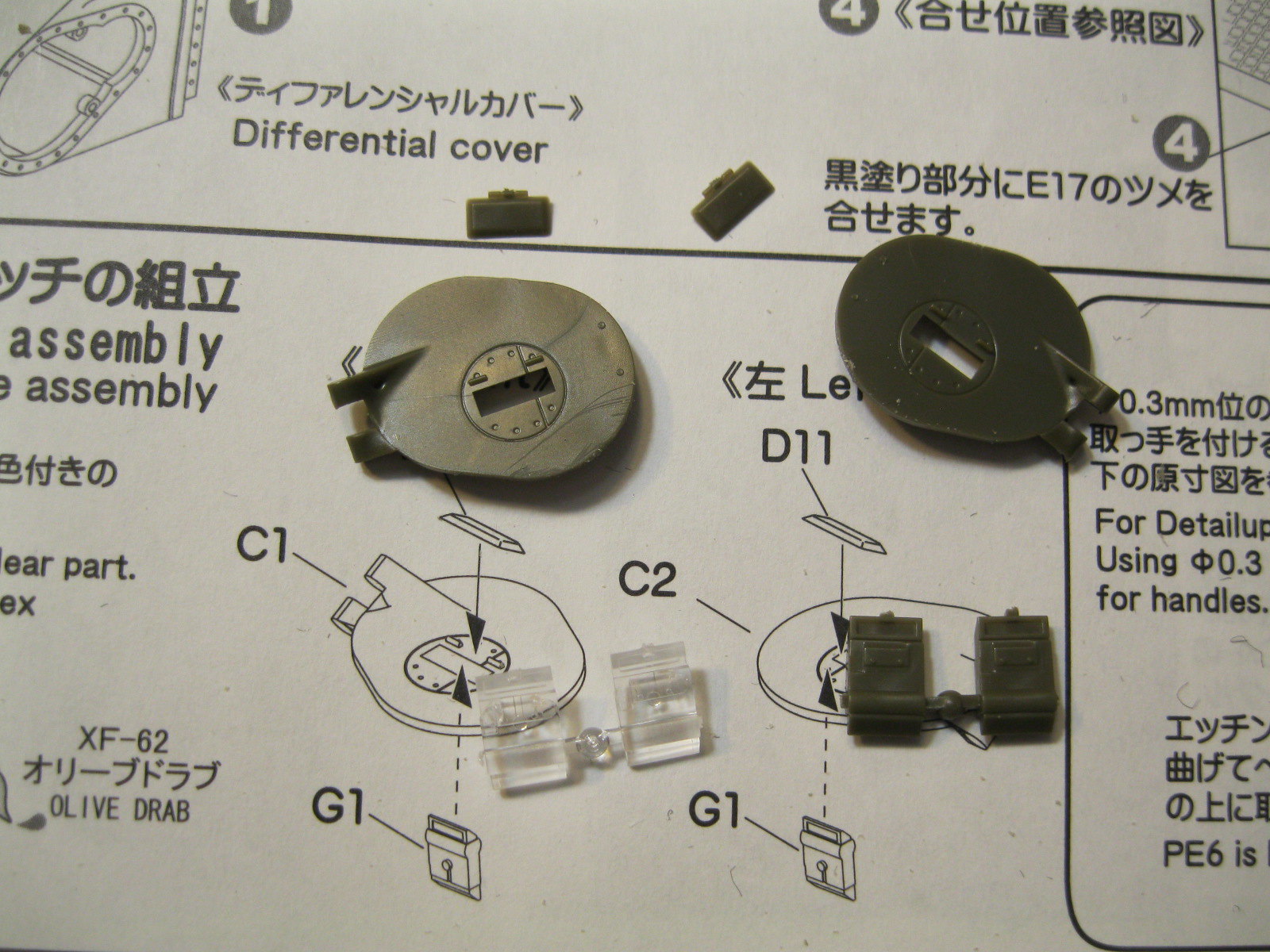

China Clipper by russell amott, on Flickr

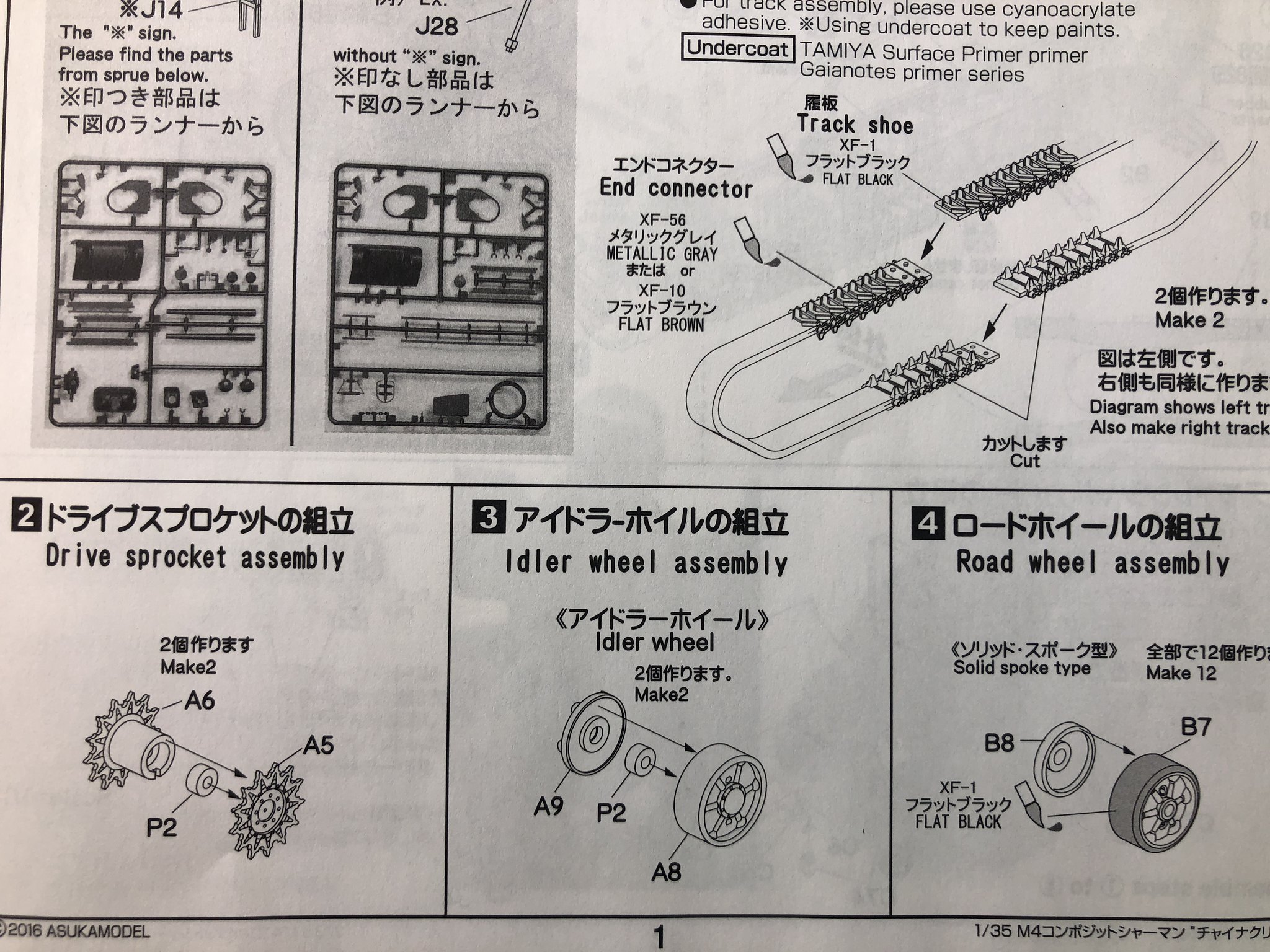

China Clipper by russell amott, on Flickr China clipper step 1 by russell amott, on Flickr

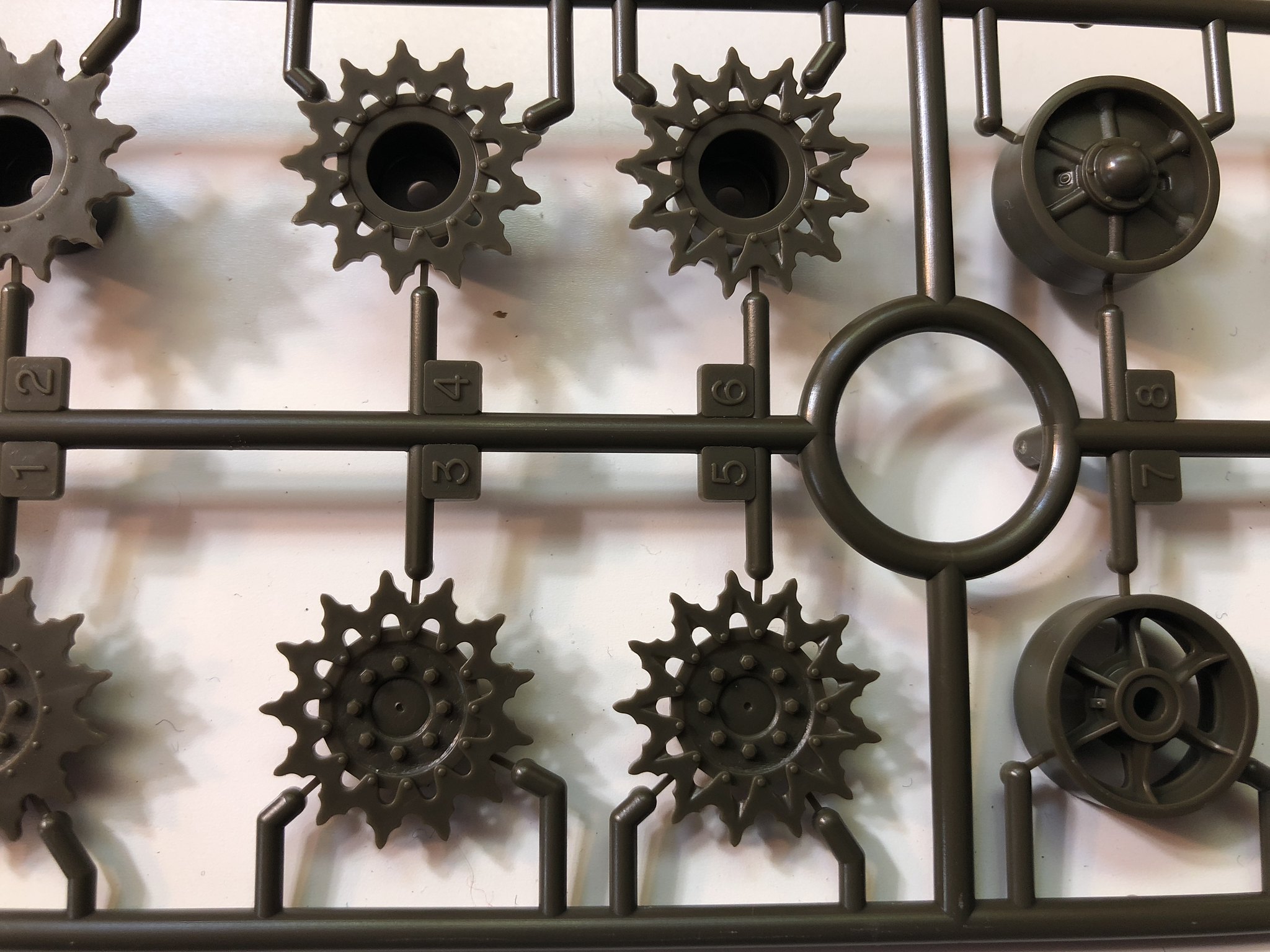

China clipper step 1 by russell amott, on Flickr China Clipper fancy drive sprocket by russell amott, on Flickr

China Clipper fancy drive sprocket by russell amott, on Flickr China clipper drive and idler by russell amott, on Flickr

China clipper drive and idler by russell amott, on Flickr