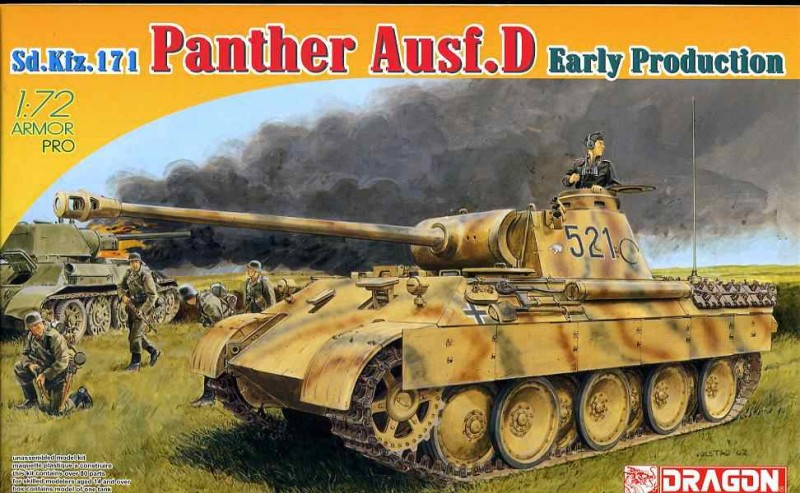

Jan Etal provides an in-depth review and build of the newly released Dragon 1/72 Panther Ausf D.

Link to Item

If you have comments or questions please post them here.

Thanks!

Armor/AFV

For discussions on tanks, artillery, jeeps, etc.

For discussions on tanks, artillery, jeeps, etc.

Hosted by Darren Baker, Mario Matijasic

REVIEW

Dragon 1/72 Panther Ausf D

BigSmitty

Joined: October 01, 2008

KitMaker: 597 posts

Armorama: 439 posts

Posted: Sunday, September 02, 2012 - 12:13 PM UTC

tread_geek

Joined: March 23, 2008

KitMaker: 2,847 posts

Armorama: 2,667 posts

Posted: Monday, September 03, 2012 - 05:06 AM UTC

Thanks for getting this one up, Matt.

As the kit was not 100% finished I'd like to invite any viewers to visit the Panther D Blog. While some of the same images appear in the review, the pictures have more detailed explanations appended with them.

Cheers,

Jan

As the kit was not 100% finished I'd like to invite any viewers to visit the Panther D Blog. While some of the same images appear in the review, the pictures have more detailed explanations appended with them.

Cheers,

Jan

weathering_one

Joined: April 04, 2009

KitMaker: 458 posts

Armorama: 456 posts

Posted: Monday, September 03, 2012 - 01:29 PM UTC

Hey Jan,

Finally! Good review and the sprue detail pics are what I wanted to see. I have a few questions but didn't know if to ask them here or in the blog?

Regards,

AJ

Finally! Good review and the sprue detail pics are what I wanted to see. I have a few questions but didn't know if to ask them here or in the blog?

Regards,

AJ

firstcircle

Joined: November 19, 2008

KitMaker: 2,249 posts

Armorama: 2,007 posts

Posted: Tuesday, September 04, 2012 - 12:43 AM UTC

Jan, you wrote:

In my SdKfz263 review, I wrote:

The detailing on the wheel guards mystifies in terms of how decisions were made as to which details are moulded on and which are separate parts; that big storage box on the right hand front fender, for example, is just a piece of additional stowage, but is moulded on, as are the fire extinguisher and shovel, both items that you might want to paint separately and which should be cylindrical in section, while B10 and 20, thin flat boxes, standard to this vehicle type, are pointlessly presented as separate parts.

In your Panzer III N review you wrote:

While an interesting subject and in many ways a beautifully detailed kit, this offering from Dragon is rather perplexing. It is as if two separate minds or purposes designed this kit, with one opting for the minute ďDragon detailĒ pieces of the past, and another introducing attempts to limit parts-count and speed assembly. To this reviewer it seems that we end up with a compromise between the two schools of thought that may not satisfy the majority of builders who prefer one or the other.

Something of a pattern developing in Dragon's recent 1/72 scale offerings. I was wondering how much of it is connected with their desire to get more than one version from the same parts, and thus decisions are more driven by being able to use sprues again in different boxes rather than the immediate consideration of the specific subject. That makes sense in some instances, but not sure about all.

Then there are the enigmas of the instructions; it's almost as if the authors of the instructions haven't built the kit... which knowing the nature of business practice sounds entirely plausible, yet totally non-sensical.

Quoted Text

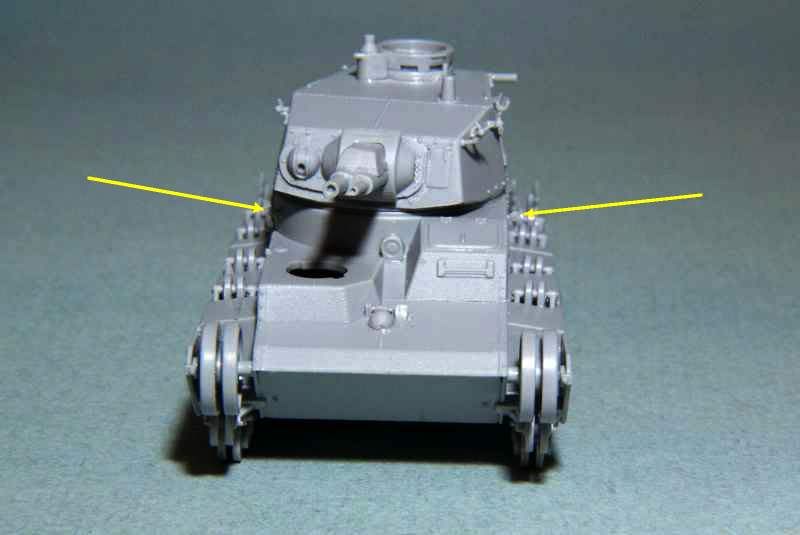

To this reviewer this kit appears to be contradictory in terms of its components/engineering. It leaves one wondering as to why some smaller parts, in some cases tiny, are provided separately whilst others that could be provided separately are moulded integrally into larger parts.

In my SdKfz263 review, I wrote:

The detailing on the wheel guards mystifies in terms of how decisions were made as to which details are moulded on and which are separate parts; that big storage box on the right hand front fender, for example, is just a piece of additional stowage, but is moulded on, as are the fire extinguisher and shovel, both items that you might want to paint separately and which should be cylindrical in section, while B10 and 20, thin flat boxes, standard to this vehicle type, are pointlessly presented as separate parts.

In your Panzer III N review you wrote:

While an interesting subject and in many ways a beautifully detailed kit, this offering from Dragon is rather perplexing. It is as if two separate minds or purposes designed this kit, with one opting for the minute ďDragon detailĒ pieces of the past, and another introducing attempts to limit parts-count and speed assembly. To this reviewer it seems that we end up with a compromise between the two schools of thought that may not satisfy the majority of builders who prefer one or the other.

Something of a pattern developing in Dragon's recent 1/72 scale offerings. I was wondering how much of it is connected with their desire to get more than one version from the same parts, and thus decisions are more driven by being able to use sprues again in different boxes rather than the immediate consideration of the specific subject. That makes sense in some instances, but not sure about all.

Then there are the enigmas of the instructions; it's almost as if the authors of the instructions haven't built the kit... which knowing the nature of business practice sounds entirely plausible, yet totally non-sensical.

tread_geek

Joined: March 23, 2008

KitMaker: 2,847 posts

Armorama: 2,667 posts

Posted: Tuesday, September 04, 2012 - 04:31 AM UTC

Quoted Text

Something of a pattern developing in Dragon's recent 1/72 scale offerings. I was wondering how much of it is connected with their desire to get more than one version from the same parts, and thus decisions are more driven by being able to use sprues again in different boxes rather than the immediate consideration of the specific subject. That makes sense in some instances, but not sure about all.

There is considerable speculation on this subject and unfortunately no consensus. Dragon is definitely reusing sprues to save mould production costs but they have pretty much done this in the past, hence their notoriety for marking unused parts in a kit. However, this appears to be being taken to some extreme. In a new kit that I am reviewing (one of a series of three variants) a sprue containing 27 parts has all but 7 marked as unused. Another sprue of this kit has 17 unused parts out of 54 present. Several of these parts are quite large and consume quite a bit of plastic. Obviously, starting with the initial release of the first variant limited forethought had been given to this by engineering.

From some information that I have come across many believe that Dragon is placing more emphasis on "ready made" or pre-assembled models. I have read that the market for these in the far east is vibrant, to say the least. Simplification means faster assembly time and therefore reduced labour costs. Yet with many of these recent kits there are parts provided that are nearing infinitesimal in size. Example is the tiny lights that reside just below the turret on the Neubau-Fahrzeug.

My finest tweezers were barely capable of holding these in a useful manner.

Quoted Text

Then there are the enigmas of the instructions; it's almost as if the authors of the instructions haven't built the kit... which knowing the nature of business practice sounds entirely plausible, yet totally non-sensical.

I have a friend that was a pattern-maker (created moulds for aerospace components) who is also an avid Braille modeller. According to him it is blatantly evident that there is a lack of communication between parties in the mould making process and yes, he states with certainty, nobody is building the thing or in some cases has a clue of what they are designing or working on.

Thanks for dropping in and commenting.

Dragon kits still rank near the top of the industry but some may turn away from them if the frustration factor contines.

Dragon kits still rank near the top of the industry but some may turn away from them if the frustration factor contines.Cheers,

Jan

Posted: Thursday, September 06, 2012 - 08:26 PM UTC

@tread_geek Ė Jan,

Youíve done a super job on this review. The photographs are of excellent quality and shows off the kits parts to good advantage. This review along with the build log that Iíve been following will compliment and complete this project leaving no issues unturned. Iím happy you mentioned about the lack of spare track links for the storage racks along the hulls sides, a horrible omission by Dragon as these items are quite the fixture in photographs of these tanks and a much needed item in the field! This is the same equivalent as anyone having to walk through Californiaís Death Valley desert for a day without any water to drink.

I noticed in your close up photographs that Dragon decided to go for a molded on idler wheel shaft. It will be interesting to see how you will fit the DS tracks on the kit without any means of adjustment for tension? Some of their kits do require some adjustment in order to accommodate for too long or too short on the track length and in some case Dragon has supplied the modeler with separate idler shafts for just this purpose. Donít misunderstand me Iím just observing and wondering what I will be contenting with when I do get this kit in my hands.

I often wonder whatís around the corner? There is always room for improvement and the competition for the mighty dollar is king in any business. You may be on top today but not tomorrow Ė that is a certainty!

~ Eddy

Youíve done a super job on this review. The photographs are of excellent quality and shows off the kits parts to good advantage. This review along with the build log that Iíve been following will compliment and complete this project leaving no issues unturned. Iím happy you mentioned about the lack of spare track links for the storage racks along the hulls sides, a horrible omission by Dragon as these items are quite the fixture in photographs of these tanks and a much needed item in the field! This is the same equivalent as anyone having to walk through Californiaís Death Valley desert for a day without any water to drink.

I noticed in your close up photographs that Dragon decided to go for a molded on idler wheel shaft. It will be interesting to see how you will fit the DS tracks on the kit without any means of adjustment for tension? Some of their kits do require some adjustment in order to accommodate for too long or too short on the track length and in some case Dragon has supplied the modeler with separate idler shafts for just this purpose. Donít misunderstand me Iím just observing and wondering what I will be contenting with when I do get this kit in my hands.

Quoted Text

Dragon kits still rank near the top of the industry but some may turn away from them if the frustration factor contines.

I often wonder whatís around the corner? There is always room for improvement and the competition for the mighty dollar is king in any business. You may be on top today but not tomorrow Ė that is a certainty!

~ Eddy

tread_geek

Joined: March 23, 2008

KitMaker: 2,847 posts

Armorama: 2,667 posts

Posted: Friday, September 07, 2012 - 07:01 AM UTC

@Braille -

I am very glad that you have found the review informative and potentially helpful.

I've worked with the DS tracks a fair amount recently and so far they live up to the best expectations most of the time. When too short I have found that they can and do stretch quite well but one needs to take care when doing so. The finer the track the more delicate you must be in the process. I have broken and even deliberately cut the tracks (to shorten them) and have had minimal issues using regular glue to cement the pieces. I am currently working on the suspension of the Panther and how it works out will definitely be an entry in its Blog.

IMHO, it seems that several companies are "experimenting" to find the "next great thing" that will propel them to the forefront. An example is the recent kits from Airfix and Trumpeter that have most of their tracked suspension moulded as one piece, including the tracks with sag. This is surprising as Pegasus has been doing this for quite some time.

When I first started reviewing Dragon kits I noted that as time went by the parts count and intricacy of the moulding kept on increasing with each release. Over the last dozen or so kits I see the parts count diminishing yet more detail that used to be separate items being moulded on. As I've mentioned, this seems to be opposite to what we have seen in the past. Could it be that these companies are trying to find a "happy medium" between a regular kit and those meant for the wargaming crowd?

Cheers,

Jan

I am very glad that you have found the review informative and potentially helpful.

Quoted Text

I noticed in your close up photographs that Dragon decided to go for a molded on idler wheel shaft. It will be interesting to see how you will fit the DS tracks on the kit without any means of adjustment for tension? Some of their kits do require some adjustment in order to accommodate for too long or too short on the track length and in some case Dragon has supplied the modeler with separate idler shafts for just this purpose. Donít misunderstand me Iím just observing and wondering what I will be contenting with when I do get this kit in my hands.

I've worked with the DS tracks a fair amount recently and so far they live up to the best expectations most of the time. When too short I have found that they can and do stretch quite well but one needs to take care when doing so. The finer the track the more delicate you must be in the process. I have broken and even deliberately cut the tracks (to shorten them) and have had minimal issues using regular glue to cement the pieces. I am currently working on the suspension of the Panther and how it works out will definitely be an entry in its Blog.

Quoted Text

I often wonder whatís around the corner? There is always room for improvement and the competition for the mighty dollar is king in any business. You may be on top today but not tomorrow Ė that is a certainty!

IMHO, it seems that several companies are "experimenting" to find the "next great thing" that will propel them to the forefront. An example is the recent kits from Airfix and Trumpeter that have most of their tracked suspension moulded as one piece, including the tracks with sag. This is surprising as Pegasus has been doing this for quite some time.

When I first started reviewing Dragon kits I noted that as time went by the parts count and intricacy of the moulding kept on increasing with each release. Over the last dozen or so kits I see the parts count diminishing yet more detail that used to be separate items being moulded on. As I've mentioned, this seems to be opposite to what we have seen in the past. Could it be that these companies are trying to find a "happy medium" between a regular kit and those meant for the wargaming crowd?

Cheers,

Jan

woltersk

Joined: May 27, 2003

KitMaker: 1,026 posts

Armorama: 654 posts

Posted: Wednesday, September 12, 2012 - 05:43 AM UTC

Quoted Text

I've worked with the DS tracks a fair amount recently and so far they live up to the best expectations most of the time. When too short I have found that they can and do stretch quite well but one needs to take care when doing so. The finer the track the more delicate you must be in the process. I have broken and even deliberately cut the tracks (to shorten them) and have had minimal issues using regular glue to cement the pieces. I am currently working on the suspension of the Panther and how it works out will definitely be an entry in its Blog.

Jan,

To stretch the tracks do you heat them in water or hot sand? Does stretching effect how they fit on the teeth of the drive sprockets? Can you get enough to achieve the sag on non-return roller style running gear? Do I sound like an inquisitive 6 year old or what?

Keep up the good work,

Keith

tread_geek

Joined: March 23, 2008

KitMaker: 2,847 posts

Armorama: 2,667 posts

Posted: Friday, September 21, 2012 - 05:34 AM UTC

Quoted Text

Jan,

To stretch the tracks do you heat them in water or hot sand? Does stretching effect how they fit on the teeth of the drive sprockets? Can you get enough to achieve the sag on non-return roller style running gear? Do I sound like an inquisitive 6 year old or what?

Keep up the good work,

Keith

Thanks for the the comments and questions and sorry to have taken so long to answer.

Stretching - So far I have stretched these type of tracks at basically room temperature and dry. With the exception of the first (Late Production) Chi Ha tracks, I've had no issues and those tracks were only a problem because they are so delicate and I was a little too forceful. That track broke at least three times but standard Testors tube glue joined the broken pieces with no issues. With the second tracks of this type (Early Production) I was more careful and had no mishaps.

Effect on Drive Sprocket Teeth - I usually use an unstretched portion around the sprockets.

Achieving Track Sag - I don't believe that this will be a problem with DS tracks. Just stretch them along the longest straight run sections between the sprocket and idler. In the case of this kit and ones like it, it might not be so necessary as the skirts will pretty much hide the area in question. However, I have seen more than a handful of modellers here achieve quite nice looking track sag even between return roller type suspensions.

In some cases where the track is only a bit tight, just place the track over the sprocket first and then tease it around the other suspension components as the DS tracks have a nice natural elasticity. With too long tracks, just cut off a few links and then re-glue the sections with your favourite cement.

In most cases these tracks are quite forgiving but you do need to be gentle in the stretching process. As for you questions, the only inappropriate question is usually the one not asked.

Cheers,

Jan

|